Flexible texture coating and preparation method thereof

A texture coating and elastic technology, applied in the field of coatings, can solve the problems of cracking, fading and peeling, and can not solve the problem of wall cracking, and achieve the effect of obvious cost performance, simple process and outstanding construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

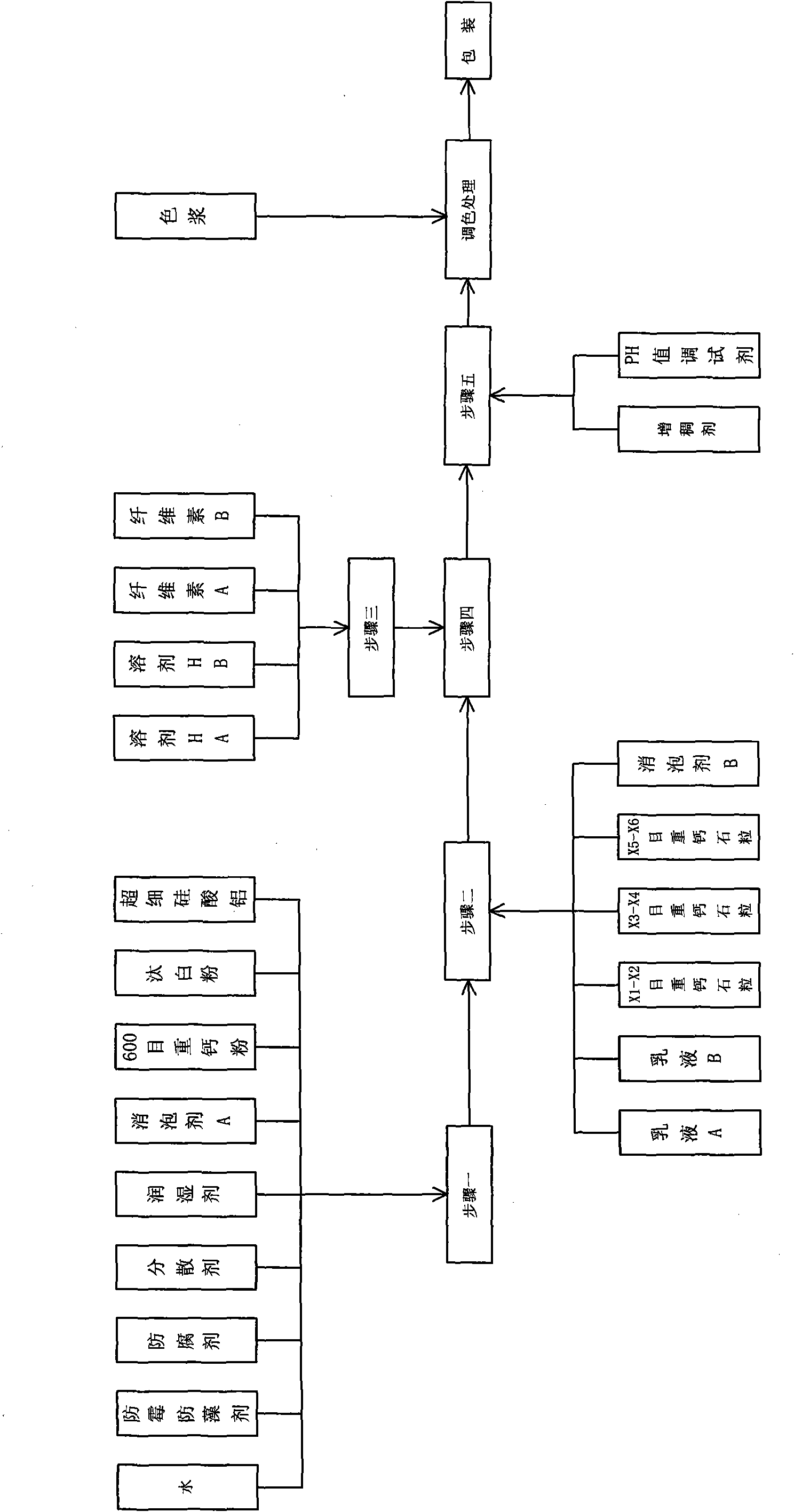

Image

Examples

Embodiment Construction

[0051]An elastic texture paint, the elastic texture paint comprises the following components and their mass percentages are: 5-10% of water, 0.1-0.3% of anti-mildew and anti-algae agents, 0.05-0.15% of preservatives, and 0.1-0.3% of dispersants %; wetting agent 0.05~0.15%, defoamer A 0.02~0.07%, 600 mesh heavy calcium powder 7.5~11.5%, titanium dioxide 10~15%, superfine aluminum silicate 1.5~3.0%, emulsion A 10~ 15%, emulsion B 15~20%, X1-X2 mesh heavy calcium stone 10~12%, X3-X4 mesh heavy calcium stone 10~12%, X5-X6 mesh heavy calcium stone 13~15%, Foaming agent B 0.05-0.15%, solvent HA 0.5-0.15%, solvent HB 1-3%, cellulose A 0.2-0.3%, cellulose B 0.1-0.2%, thickener 0.5-0.7%, pH adjustment agent 0.05~0.15%; during implementation, the concrete numerical value of above-mentioned each component, can select its intermediate value, as: water 7.25%, anti-mildew anti-algae agent 0.2% etc., no longer detailed description one by one here.

[0052] As a better embodiment, the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com