Method for using stainless steel sleeve to coat large-diameter cylinder body

A technology with stainless steel sleeves and large diameters, which is applied in the field of surface repair equipment for hydraulic support columns used in coal mines. It can solve the problems of easy failure and scrapped steel sleeves, and achieve the effects of not easy peeling, high reliability, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in further detail below.

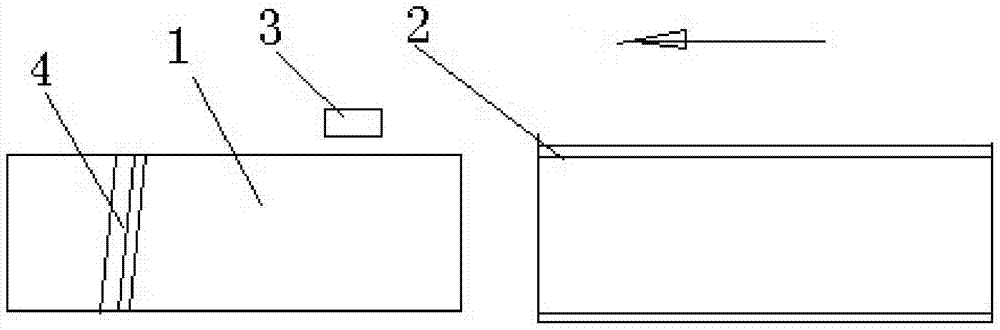

[0016] The method for outsourcing a stainless steel sleeve for a large-diameter cylinder of the present invention, its preferred specific embodiment is as follows: figure 1 shown:

[0017] Include steps:

[0018] First, lathe the outer wall of the large-diameter cylinder, make a stainless steel sleeve according to the size of the outer wall of the large-diameter cylinder, and process triangular threads on the outer wall of the large-diameter cylinder;

[0019] Then, under normal temperature, the stainless steel is sleeved outside the large-diameter cylinder;

[0020] After that, the stainless steel sleeve is rolled while being heated.

[0021] The heating temperature of the stainless steel sleeve is above 723°.

[0022] The wall thickness of the stainless steel sleeve is 1 mm to 2 mm, and the inner wall of the stainless steel sleeve and the outer wall of the large-diameter cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com