Reinforced graphene modified PVDF hollow fiber membrane and production method thereof

A technology of graphene modification and fiber membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. It can solve the problems of poor mechanical strength, easy to break, and brittle membrane filaments, and improve the sewage treatment effect , Improve anti-pollution performance, improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of preparation method of reinforced graphene modified PVDF hollow fiber membrane, its specific steps are:

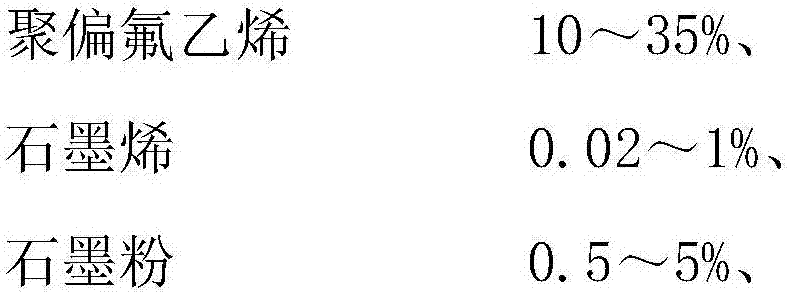

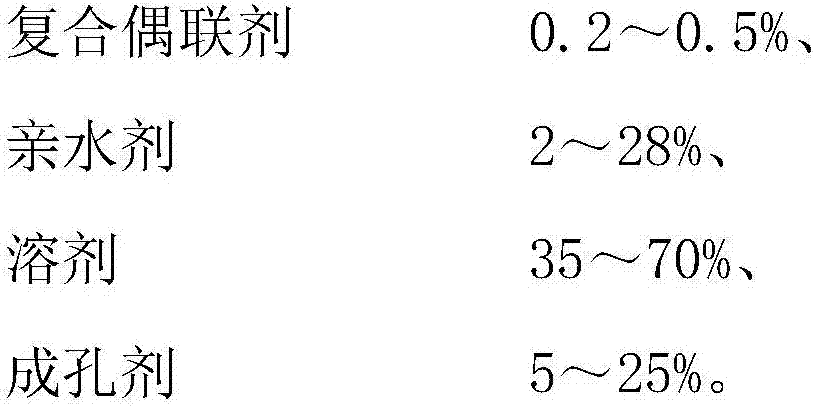

[0022] In order to effectively disperse graphene in polyvinylidene fluoride and to reduce costs, firstly, 0.02-1% graphene and 0.5-5% graphite powder are pre-mixed and microwave-dried, and then 0.2-0.5 % composite coupling agent and 10-35% polyvinylidene fluoride for high-speed mixing;

[0023] Add 2 to 28% of hydrophilic agent, 5 to 25% of pore forming agent and 35 to 70% of solvent to the ingredients after high-speed mixing, and mix again to make a film-making material; use high-temperature solvent phase inversion The graphene-modified PVDF hollow fiber membrane reinforced by the hook-woven mesh tube is prepared with the hook-woven mesh tube lamination process (temperature is 120-150°C); in this way, the graphene can be effectively and evenly dispersed in the polyvinylidene fluoride, It will not cause graphene to agglomerate and fail or reduce its effect...

Embodiment 1

[0033] Pre-mix 0.3% graphene and 3% graphite powder and then microwave dry, then add 0.3% composite coupling agent and 26.4% polyvinylidene fluoride for high-speed mixing; Add 20% hydrophilic agent, 15% pore-forming agent and 35% solvent, and mix again to make a film-making material; filter the film-making material into the spinning tank for defoaming, and control the defoaming temperature to 120°C ; Then pressurize the hollow fiber membrane composite die mouth and the hook-woven mesh tube to be combined and then separated and shaped by the solidification water tank to complete the preparation of the graphene-modified PVDF hollow fiber membrane reinforced by the hook-woven mesh tube.

[0034] The outer diameter of the hollow fiber membrane obtained in this example is 1.9 mm, the inner diameter is 0.9 mm, the porosity is 61%, and the membrane separation pore diameter is 0.08 micron, under the test conditions of 0.1 MPa and 25 ° C (detection reference standard: People's Republic ...

Embodiment 2

[0036] Pre-mix 1% graphene and 2% graphite powder and then microwave dry, then add 0.2% composite coupling agent and 35% polyvinylidene fluoride for high-speed mixing; Add 5% hydrophilic agent, 10% pore forming agent and 46.8% solvent, and mix again to make film-making material; filter the film-making material into the spinning tank for defoaming, and control the defoaming temperature to 150°C ; Then pressurize the hollow fiber membrane composite die mouth and the hook-woven mesh tube to be combined and then separated and shaped by the solidification water tank to complete the preparation of the graphene-modified PVDF hollow fiber membrane reinforced by the hook-woven mesh tube.

[0037] The hollow fiber membrane obtained in this example has an outer diameter of 1.9mm, an inner diameter of 0.9mm, a porosity of 68%, a membrane separation pore diameter of 0.1 micron, and a pure water flow rate of 850L under the test conditions of 0.1MPa and 25°C. / m 2 *hr; In the normal operati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com