Cooling and energy saving type electrolytic aluminum imaging information layer paint and preparation method thereof

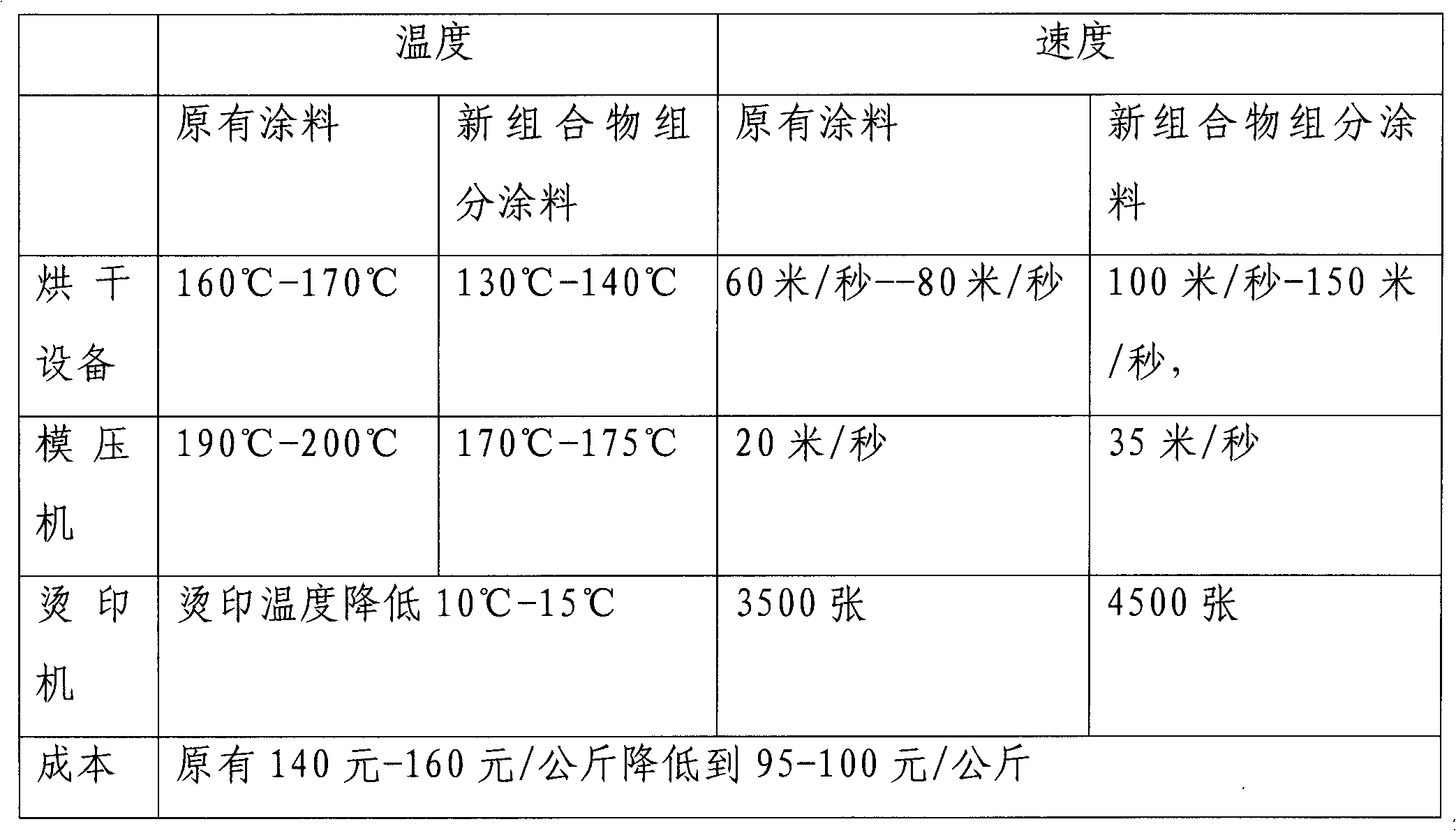

An anodized aluminum and energy-saving technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of lower product qualification rate, high cost, and large energy consumption, so as to reduce equipment processing temperature, reduce production and use costs, The effect of increasing the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: When taking 30 parts of acrylic resin, other components and parts by weight remain unchanged, that is: 20 parts of polyurethane, 1 part of organic silicon additive, 50 parts of methyl ethyl ketone, 30 parts of butyl ester, and its solid content is 35 parts %, the result is: the purpose of the invention is basically realized, the inclusion solubility of the toner is not good, some particles appear, and the uniformity of the layer is not good.

Embodiment 2

[0024] Embodiment 2: When taking 40 parts of acrylic resin, other components and parts by weight have not changed, that is: 20 parts of polyurethane, 1 part of organic silicon additive, 50 parts of methyl ethyl ketone, 30 parts of butyl ester, and its solid content is 40 parts %, the result is: the purpose of the invention is achieved, the toner has good encapsulation, good uniformity of the layer, and no dot-like particle phenomenon, so the preferred acrylic resin gets 40 parts.

Embodiment 3

[0025] Example 3: In the case of no change in other components and parts by weight, add 30 parts of polyurethane to the above reaction kettle, that is: 40 parts of acrylic resin, 1 part of silicone additive, 50 parts of methyl ethyl ketone, 30 parts of butyl ester, Its solid content is 35-40%, and as a result, the purpose of the invention is basically achieved, but it is prone to peeling, the stability of the molded layer is poor, and the phenomenon of plate sticking often occurs, and the follow-up molding temperature is required to be high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com