Structure of constraining faced wall for building

A technology for combined walls and buildings, applied in building components, building structures, buildings, etc., can solve the problems of large environmental pollution, difficult construction, high resource and energy consumption, and achieve high structural mechanical performance and seismic performance. The effect of low labor intensity and low resource and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

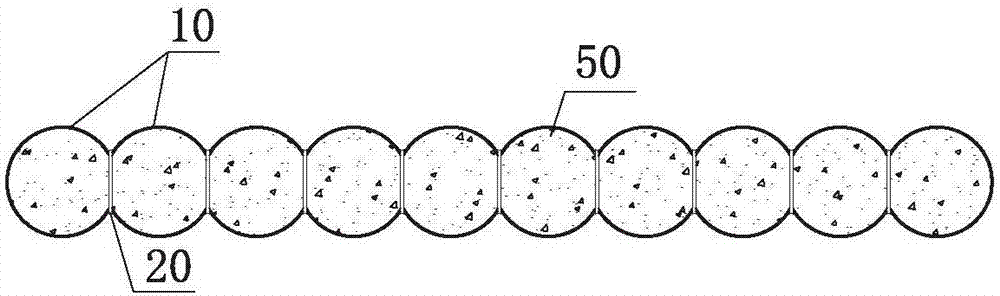

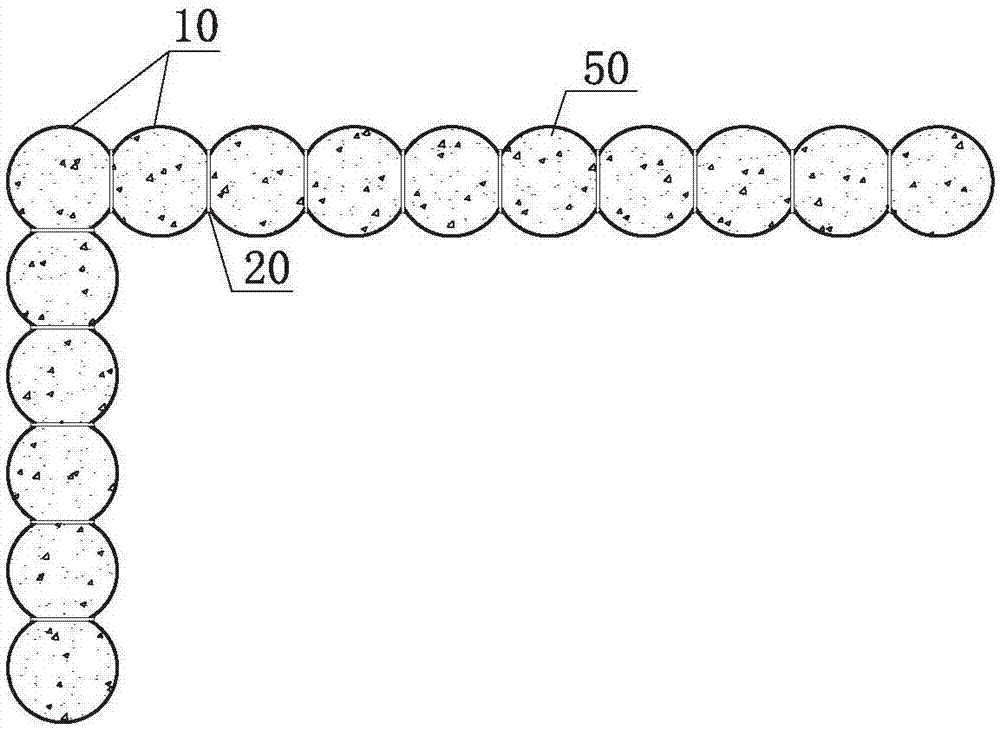

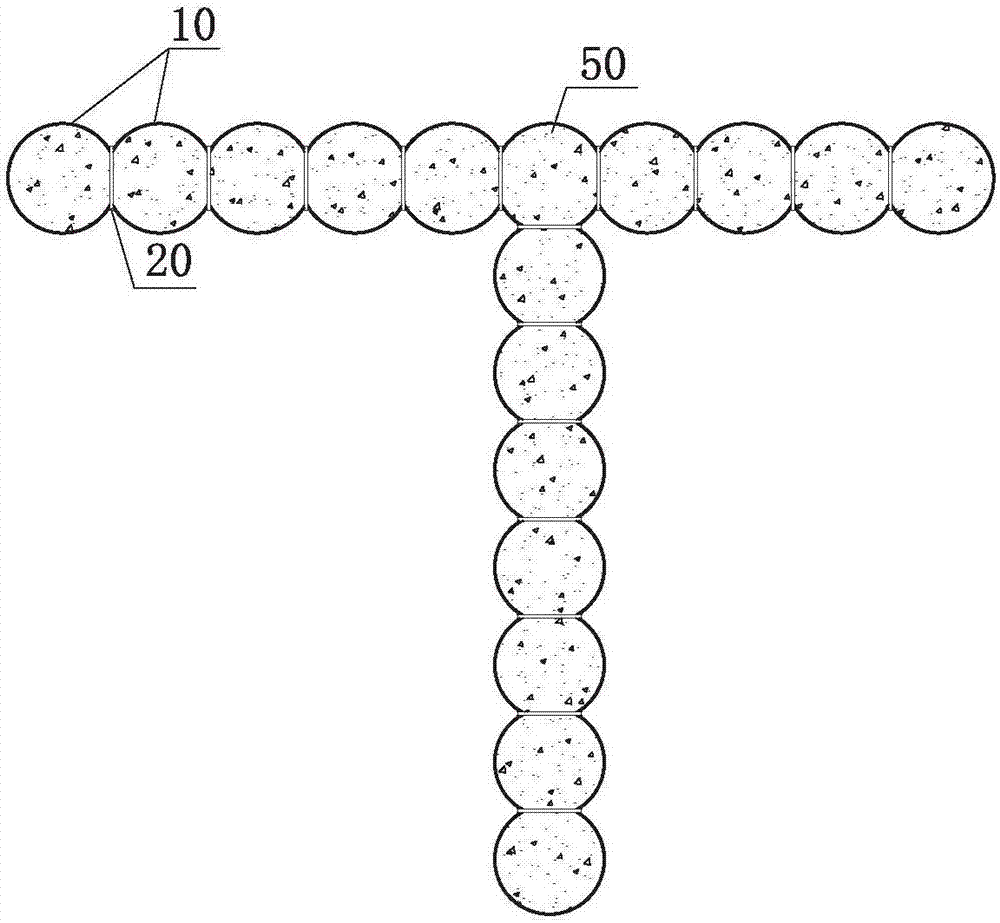

[0019] Such as Figure 1 to Figure 20 As shown, the constrained composite wall structure for construction of the present invention comprises several column units connected to each other to form a cross-section of a predetermined shape, and the aspect ratio of the cross-section is greater than 4; the column units at least include arc-shaped plates 10, and at least one column unit is filled with Filler 50, under normal circumstances, all column units should be filled with filler, but in special cases, a certain column unit or partial structure may not be filled with filler; the column unit is the first column unit, or the second and third columns A combination of units, or a combination of fourth and fifth column units, or a combination of first, second and sixth column units, or a combination of first, fourth and seventh column units, or a combination of second, third and A combination of the eighth column unit, or a combination of the first, second, sixth and eighth column uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com