Application of ribbed floors and wide flat beams in frame-core tube structure system

A core tube and floor slab technology, applied to floors, special structures, building components, etc., can solve the problems of increasing the amount of concrete and steel bars, resulting in small safety reserves, and large thickness of beamless floors, etc., to increase net height and shorten construction Period, the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

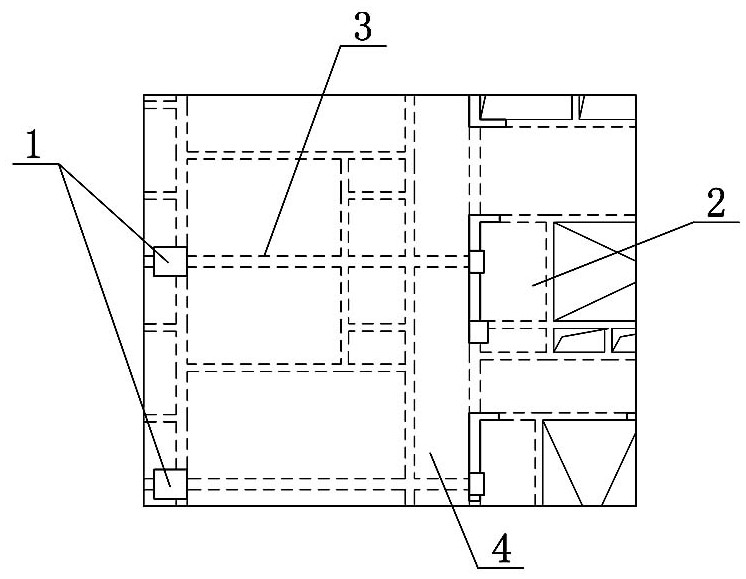

[0016] Such as figure 2 As shown, the densely ribbed floor slab and the wide flat beam described in the present invention are used as a connection structure in a high-rise building with a frame-core tube structure as a structural system. specifically:

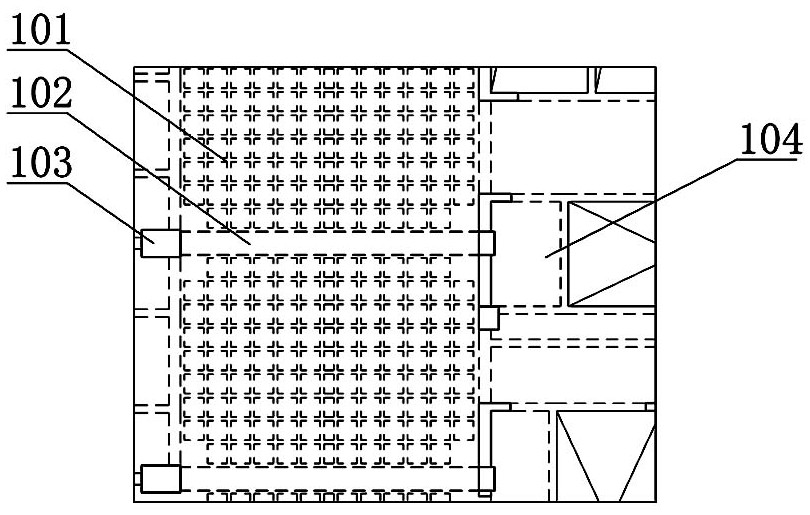

[0017] Such as figure 2 As shown, the present invention replaces traditional floor slabs with densely ribbed slabs 101, and replaces traditional frame beams with wide flat beams 102 to connect frame columns 103 and core tubes 104. The cross-sectional size of wide flat beams 102 is 600 mm×400 mm, and its height i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com