Construction method of multi-line long span inverted trapezoidal space truss roof system

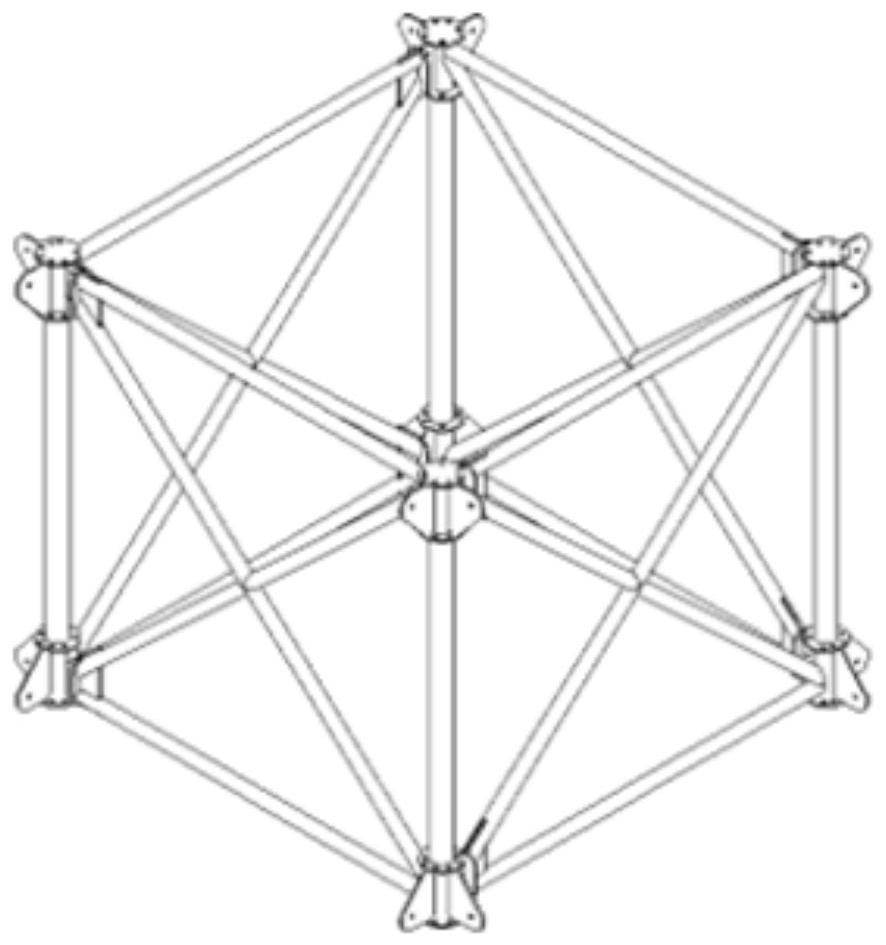

A technology of space truss and construction method, applied in the direction of roofs, building components, buildings, etc., can solve the problems of complex inverted trapezoidal roof structure, high precision requirements for processing and construction, construction and installation, and irregular shapes, so as to achieve reasonable stress, The effect of high stiffness and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

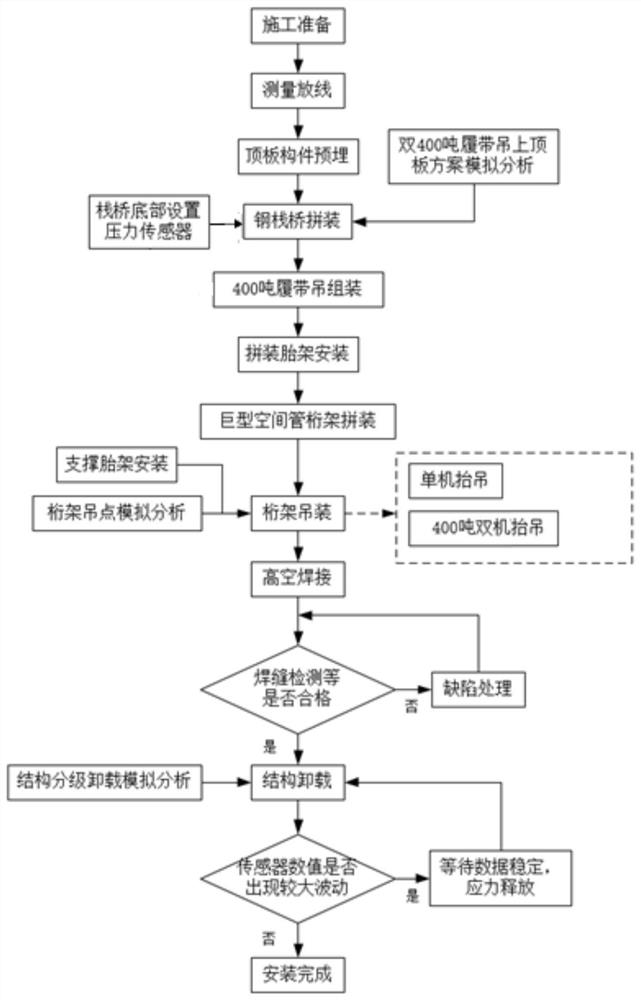

[0030] A construction method for a multi-line large-span inverted trapezoidal space truss roof system, such as figure 1 As shown, the construction method includes:

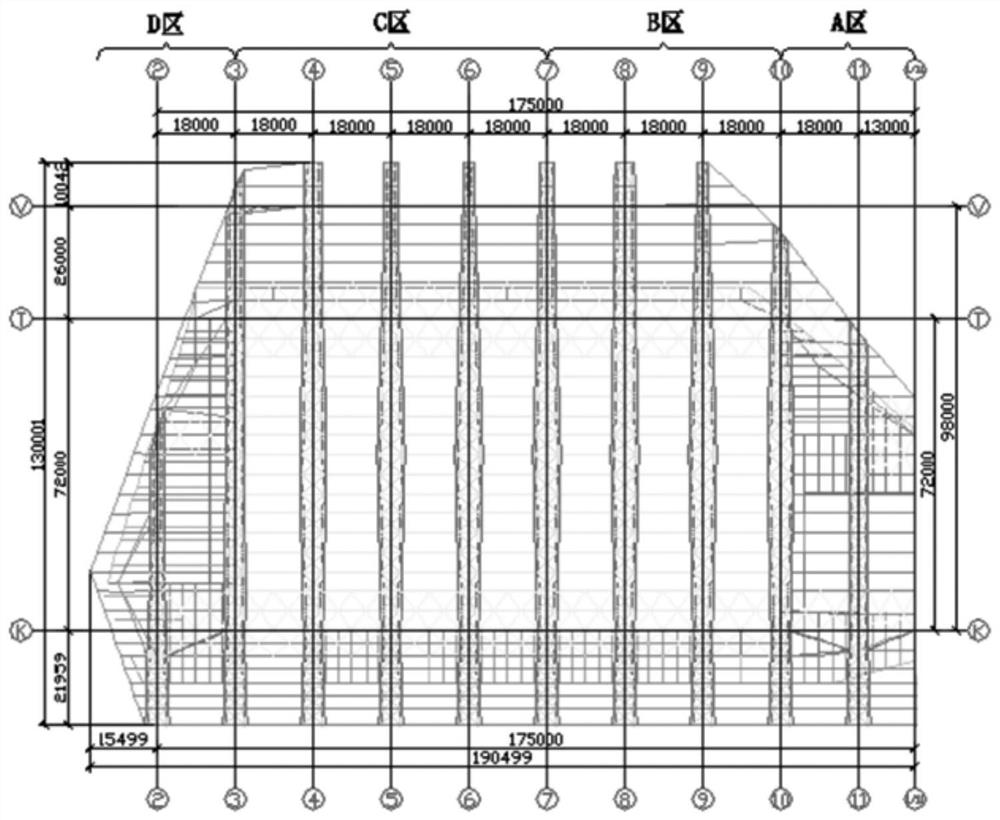

[0031] S1. Construction preparation: According to the design drawings, understand the design intent and depth, check the amount of materials and components, and review the specifications, models, and materials of the components to ensure that the design and specification requirements are met; according to the construction site, production schedule and structure Form, divide the truss into partitions, such as figure 2 Shown: The roof trusses are generally divided into four construction areas A, B, C, and D. The overall construction sequence is Area A → Area B → Area C → Area D; The hoisting sequence is as follows: install from north (12 axes) to south (1 axis); the hoisting machinery is: use two 400-ton crawler cranes for segmental hoisting; use 250-ton and 150-ton crawler cranes to assist truss assembly, bodile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com