Precast pile and bearing platform fabricated type foundation tenon type flange connecting structure and construction method

A connection structure and prefabricated technology, applied in infrastructure engineering, construction, etc., can solve the problems of occupying site space and large workload, and achieve the effect of accelerating construction speed, reasonable structure, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

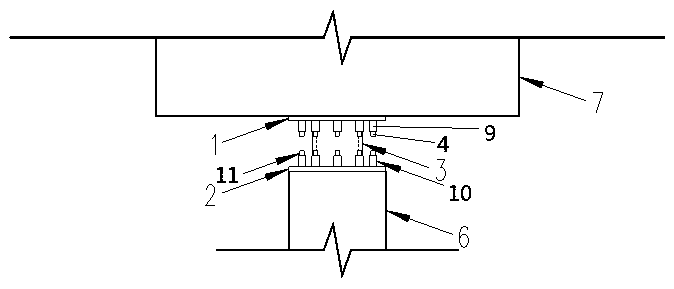

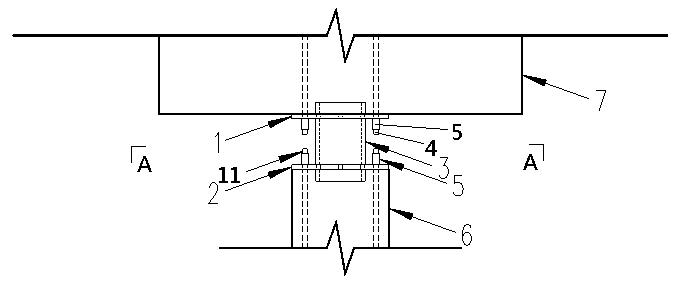

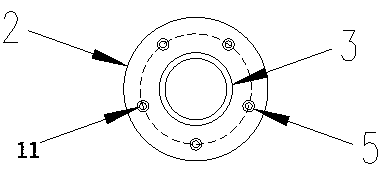

[0020] Such as Figure 1~5 As shown, a prefabricated pile-cap assembly foundation tenon-type flange connection structure includes pipe piles 6 and caps 7, a supporting steel pipe 3 is arranged between the pipe piles 6 and the cap 7, and the lower end of the supporting steel pipe 3 A lower flange 2 fitted to the end face of the pipe pile 6 is set, an upper flange 1 fitted to the end face of the cap 7 is set on the upper end of the supporting steel pipe 3, and an end is pierced on the upper flange 1 Insert the upper threaded steel 4 of the platform 7, the other end of the upper threaded steel 4 is provided with an upper fastening nut 5 for locking the upper flange 1 on the lower end surface of the platform 7, and the lower flange 2 is pierced One end is inserted into the upper fastening mechanism 9 of the pipe pile 6, and the other end of the lower threaded steel 11 is provided with a lower fastening mechanism 10 for locking the lower flange 2 on the end surface of the pipe pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com