Construction method of cast-in-place concrete curve surface inclined tube body structure

A construction method and concrete technology, which are applied in the construction of cast-in-place reinforced concrete structures and the construction of cast-in-place concrete curved inclined cylinder structures, can solve the problems of difficulty in supporting the curved formwork, difficult control of the appearance quality of finished products, etc., so as to achieve the appearance quality The effect of easy control, simple construction and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

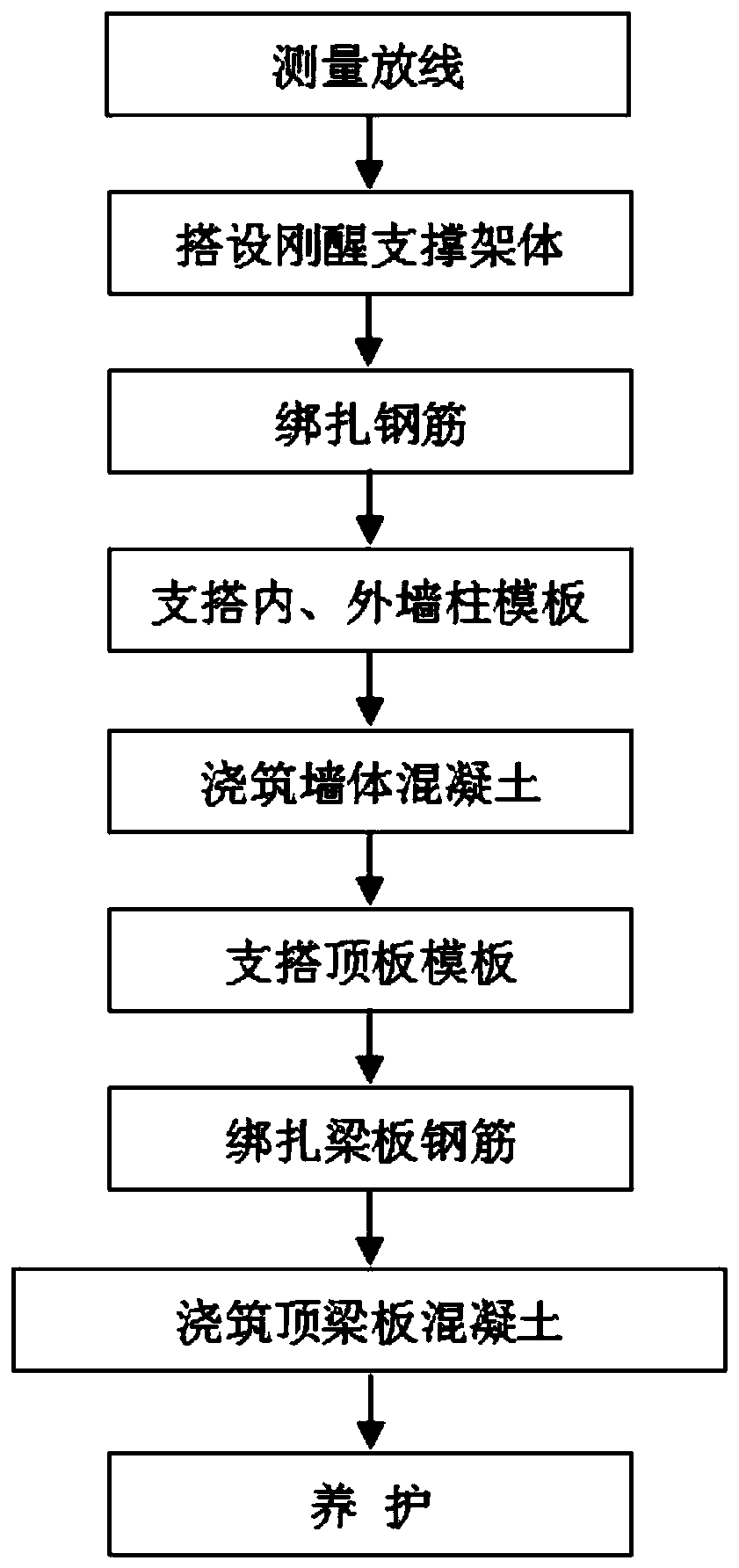

[0030] A kind of construction method of cast-in-place concrete curved inclined cylinder structure described in this embodiment, such as figure 1 ,Specific steps are as follows:

[0031] Step 1, measuring and setting out:

[0032] In the underground stage, according to the control points of the building outside the foundation, the control line is projected by the direction method or the straight line method of the front and back mirrors, and the distance between the adjacent axis and the adjacent axis is correct before use.

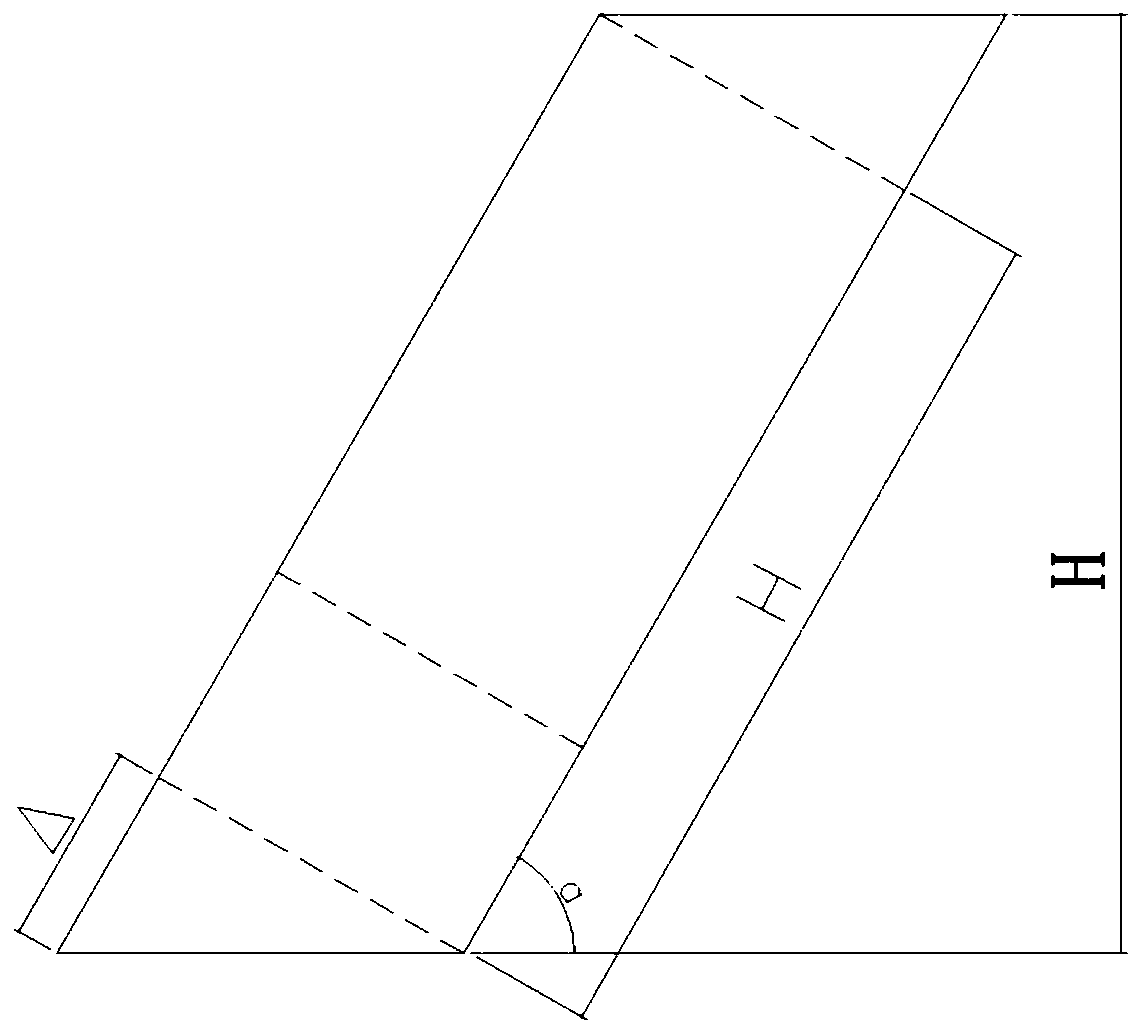

[0033] Since the starting line of the plane position of the inclined wall column is closely related to the elevation, before the floor is laid out, the floor elevation of the position to be set out is generally measured with a level, and the highest value is taken as the elevation of the plane position li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com