Hoistway inner hoisting frame for core tube elevator shaft steel beam installation and steel beam construction method

A lifting frame and core tube technology, which is applied in the direction of vertical pipelines, transportation and packaging, and load hanging components, can solve the problems of high construction risk, cumbersome construction, and low construction efficiency, so as to reduce the risk of object strikes, reduce the The cost of construction measures and the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

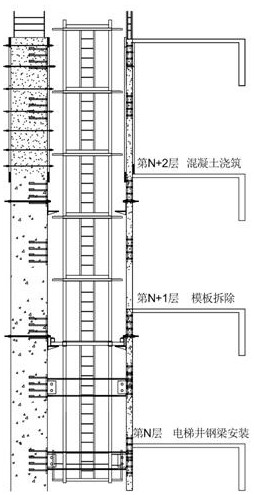

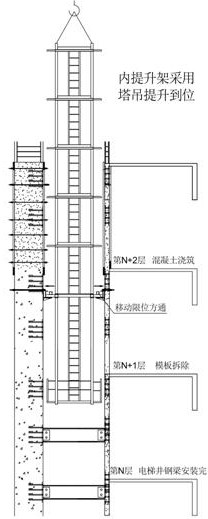

[0027] Such as Figure 1-9 Shown: a lifting frame in the hoistway for installing steel beams in a core tube elevator shaft. The lifting frame body is arranged in the elevator shaft 10 of the core tube shear wall 11. The lifting frame body is a rectangular frame, which includes six floors, and the bottom layer is a The first floor is for the installation of elevator steel beam 8, and its floor height is the building standard floor height. The upper five floors are for concrete structure construction. From top to bottom, they are: steel bar binding, formwork removal, and their floor height is the floor height half.

[0028] The fixing method of the lifting frame body and the core tube shear wall is as follows: the core tube shear wall is pre-embedded with plastic sleeves, and holes are reserved; the diameter of 28mm round steel is used as the wall-penetrating screw, and the two ends of the screw are tapped. The nut fixes the attached wall fitting, the attached wall fitting is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com