Cable tensioning device

A tensioning device and power device technology, applied in the processing of building materials, construction, bridge construction, etc., can solve problems such as the danger of high-altitude work, large tensioning construction force, and workers unable to construct, and reduce the impact of heavy objects. Risk, hazard reduction, labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

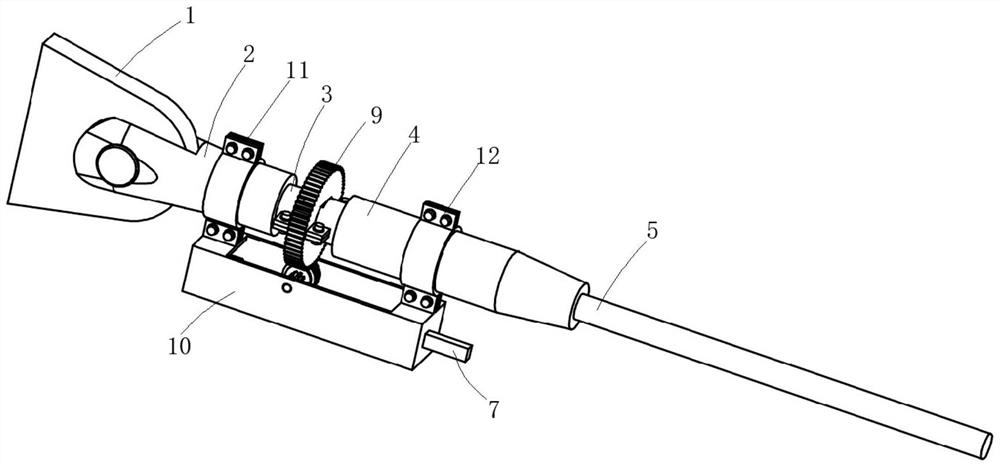

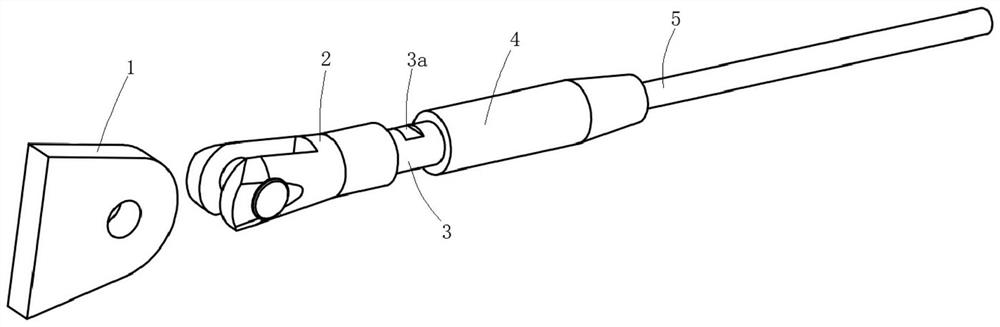

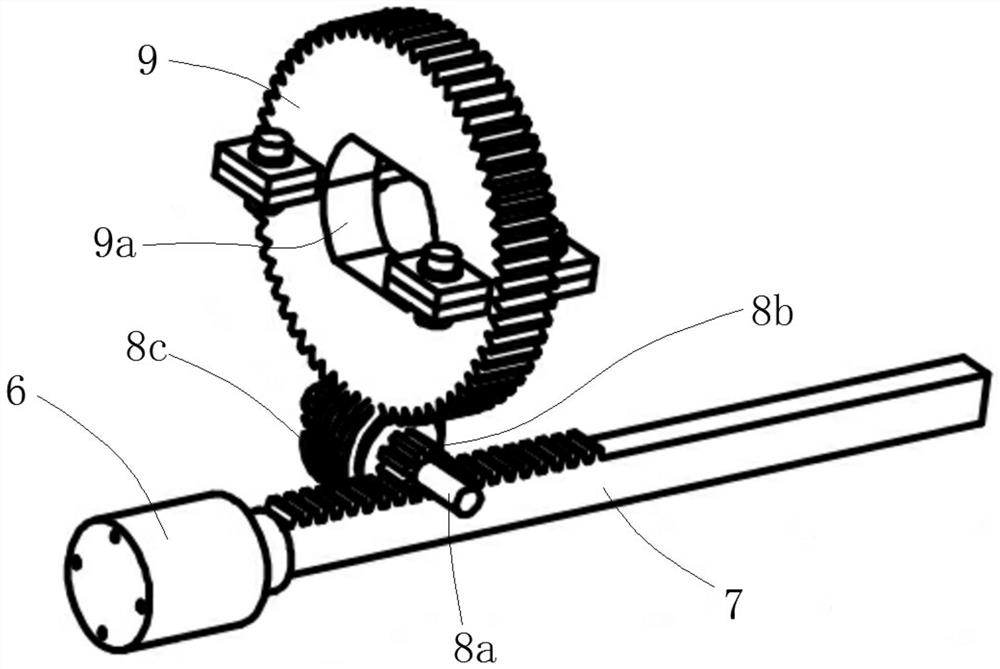

[0049] The cable tensioning device has the advantages of low labor intensity, high reliability, suitable for extreme environments, and safe use, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, specifically set to the following structure:

[0050] The gusset plate 1, the fork lug anchorage 2, the connection nut 3 and the connection anchorage 4 are sequentially connected along the length direction of the cable 5; The anchor 2 is connected to the gusset plate 1 through a pin shaft, and the connecting anchor 4 is fixedly connected with a stay cable 5 .

[0051] A power device is provided on the cable tensioning device, the input end of the power device is used to connect with a remote control device to realize the purpose of remotely controlling the rotation of the connecting nut 3, and the output end of the power device is connected to the connecting nut 3 And it is used to drive the connecting nut 3 to rotate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com