Novel multibarrel tube-confined concrete pier column

A concrete-filled steel tube and concrete technology, which is applied to piers, columns, pillars, etc., can solve the problems of poor restraint performance and can not ensure the three-dimensional stress state of concrete, achieve high anti-collapse ability, reduce engineering costs, and be economical. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

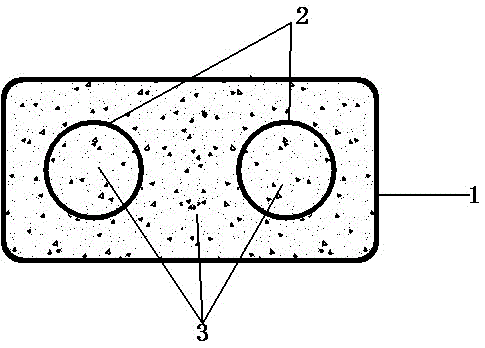

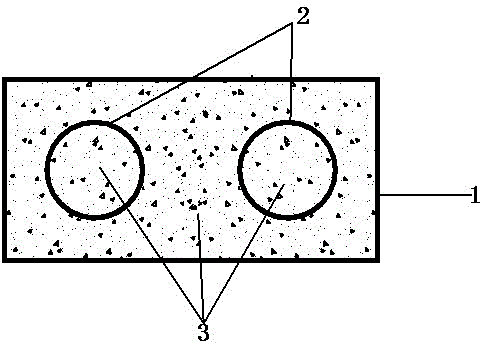

[0012] The present invention will be described in detail below with reference to the accompanying drawings. The compound concrete-filled steel pipe pier of the present invention is a cross-sectional form of double-circular steel pipes inside a rectangular concrete-filled steel pipe, including two layers of steel pipes inside and outside, the outer steel pipe 1 is a rectangular steel pipe, the inner steel pipe 2 is two round steel pipes, and the steel pipes are filled with concrete 3. Such as figure 1 , 2 Shown is the plan view of the composite steel pipe concrete pier.

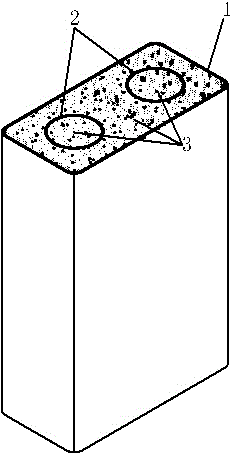

[0013] Such as image 3 , 4 It is the elevation view of the composite steel pipe concrete pier structure. Two round steel pipes are symmetrically arranged at both ends of the rectangular steel pipe in the longitudinal direction, which can improve the compression, bending and shear resistance of the pier.

[0014] In the novel composite steel pipe concrete pier column, the outer steel pipe is a rounded rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com