The nodes and construction method for concrete filled steel tubular column and in-situ reinforced concrete beam

A technology for concrete-filled steel tubular columns and reinforced concrete beams, which is applied to buildings and building structures, can solve the problems of complex node connection, unclear force transmission paths, and many on-site welding processes, and achieves convenient construction, less welding processes, The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

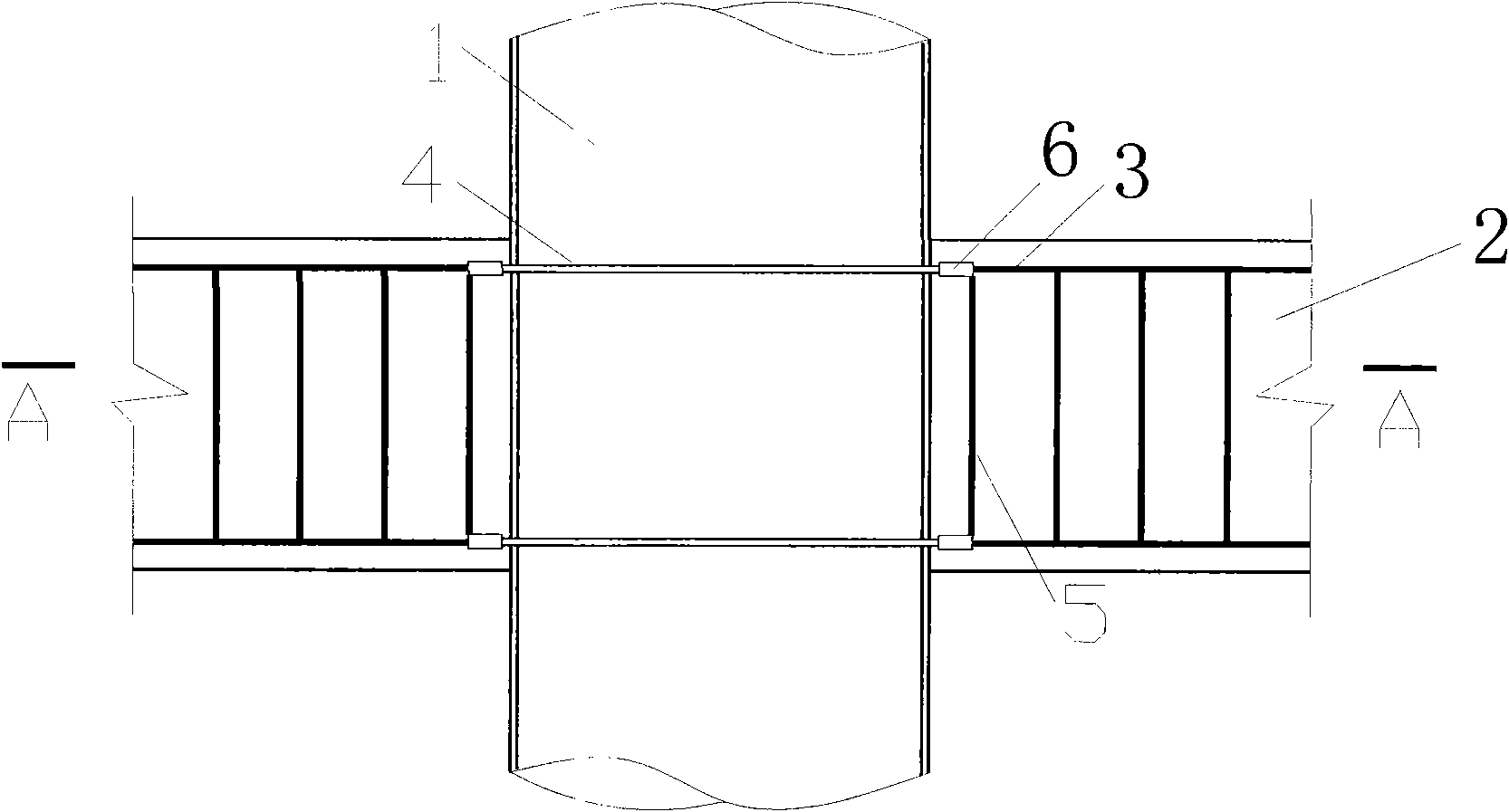

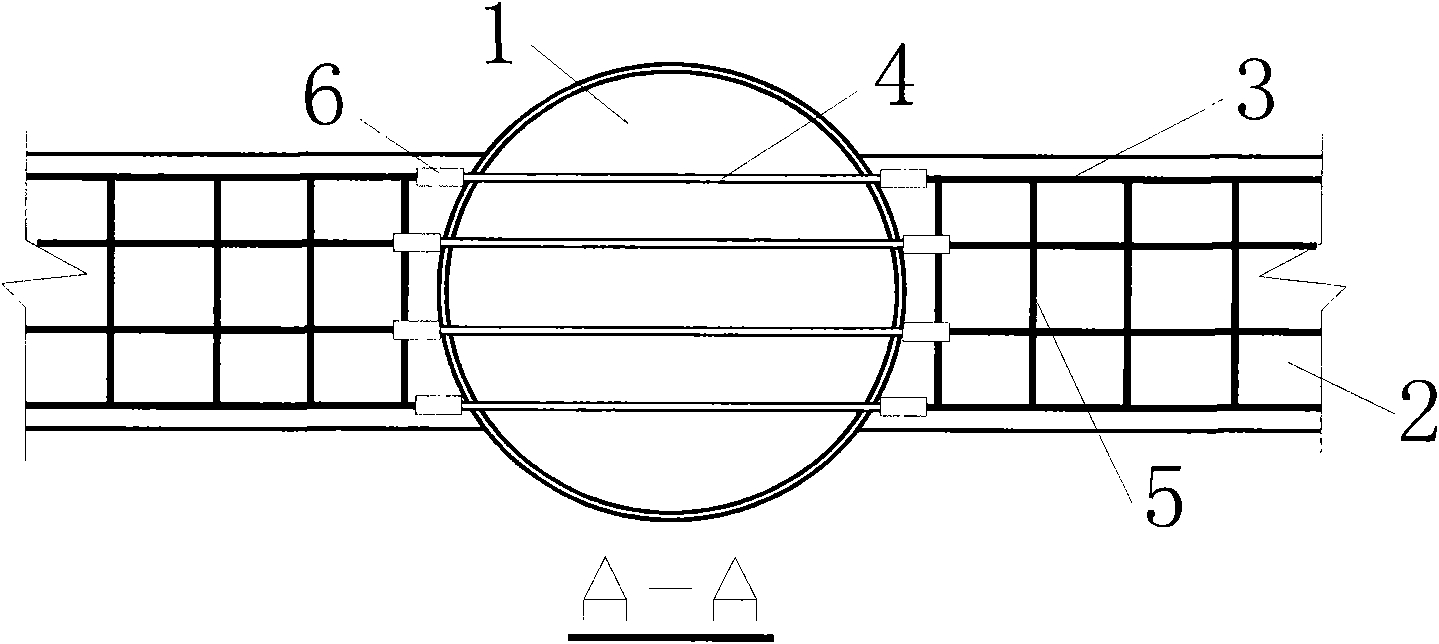

[0020] The joints between concrete filled steel tube columns and cast-in-place reinforced concrete beams are as follows: figure 1 Shown: the steel pipe in the steel tube concrete column 1 is drilled in the steel structure processing plant, and the threaded tie rod 4 and the steel casing 6 are threaded in advance, and the length of the threaded thread in the through tie rod 4 is greater than 100mm. Pass the center tie rod 4 through the upper hole of the steel tube concrete column 1, and put steel sleeves 6 on both ends. After the steel tube in the steel tube concrete column 1 is positioned, the longitudinal reinforcement 3 in the beam is threaded with the steel sleeve 6, and then the stirrup 5 is screwed together. Binding, the spacing is 50-80mm, after the steel bars in the beam are bound, pour the steel pipe and the concrete in the beam.

Embodiment 2

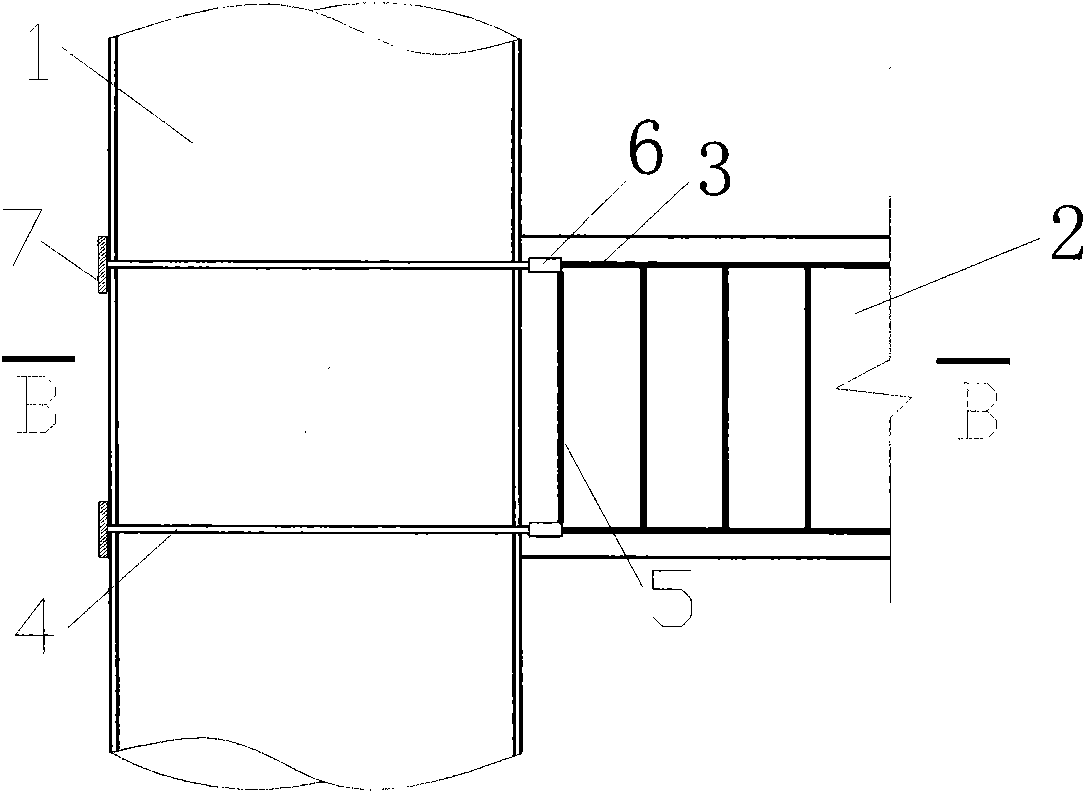

[0022] See when it is a side column node figure 2 , Other measures are the same as in Embodiment 1, except that the ring plate 7 is used at the end of the side column, and one end of the through-center tie rod 4 is welded to the ring plate to increase the anchoring performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com