Light concrete internal and external corner structure in prefabricated building and installation method

A light-weight concrete and prefabricated technology, which is applied in the direction of building structure, construction, floor, etc., can solve the problems that the internal and external corners of concrete cannot be preset with household wires, etc., and achieve the effects of facilitating popularization and use, simple operation, and avoiding difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

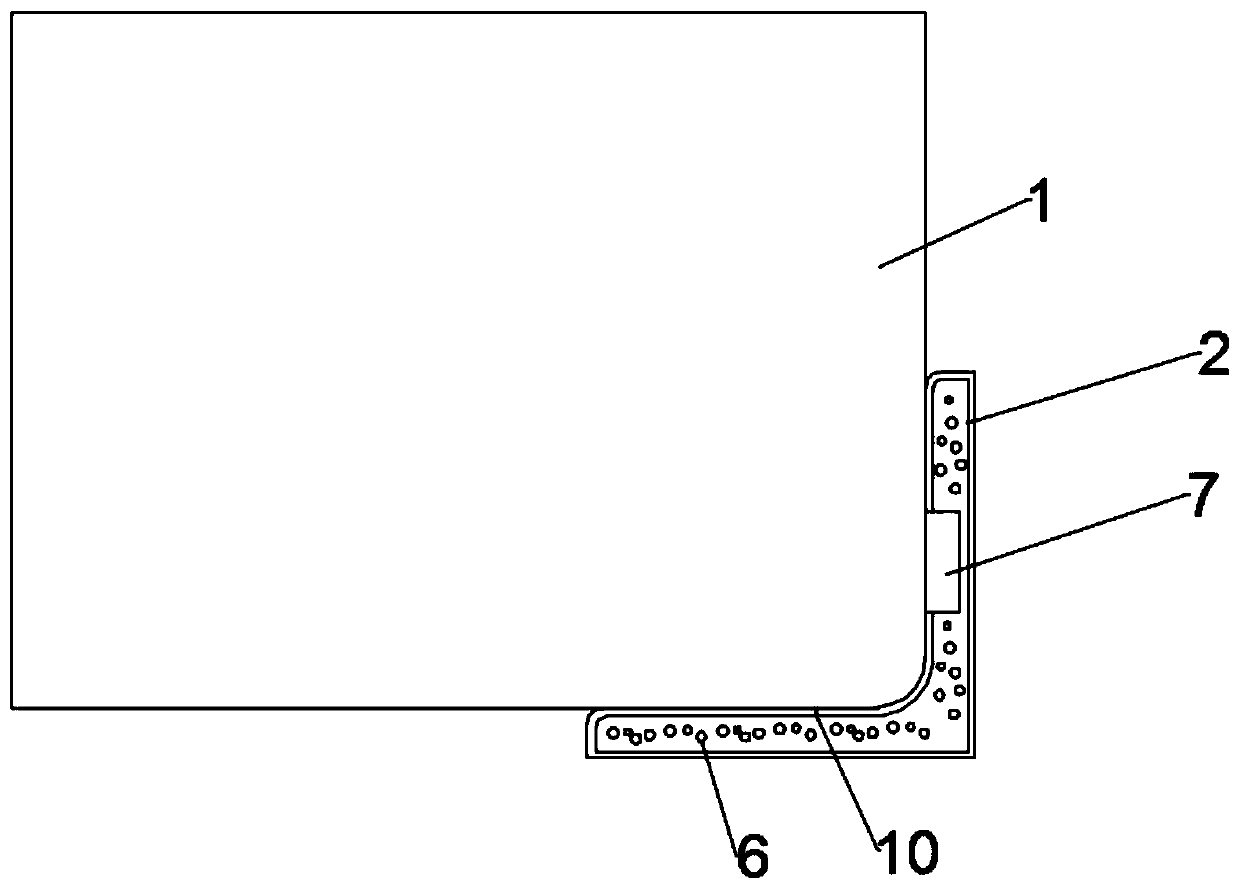

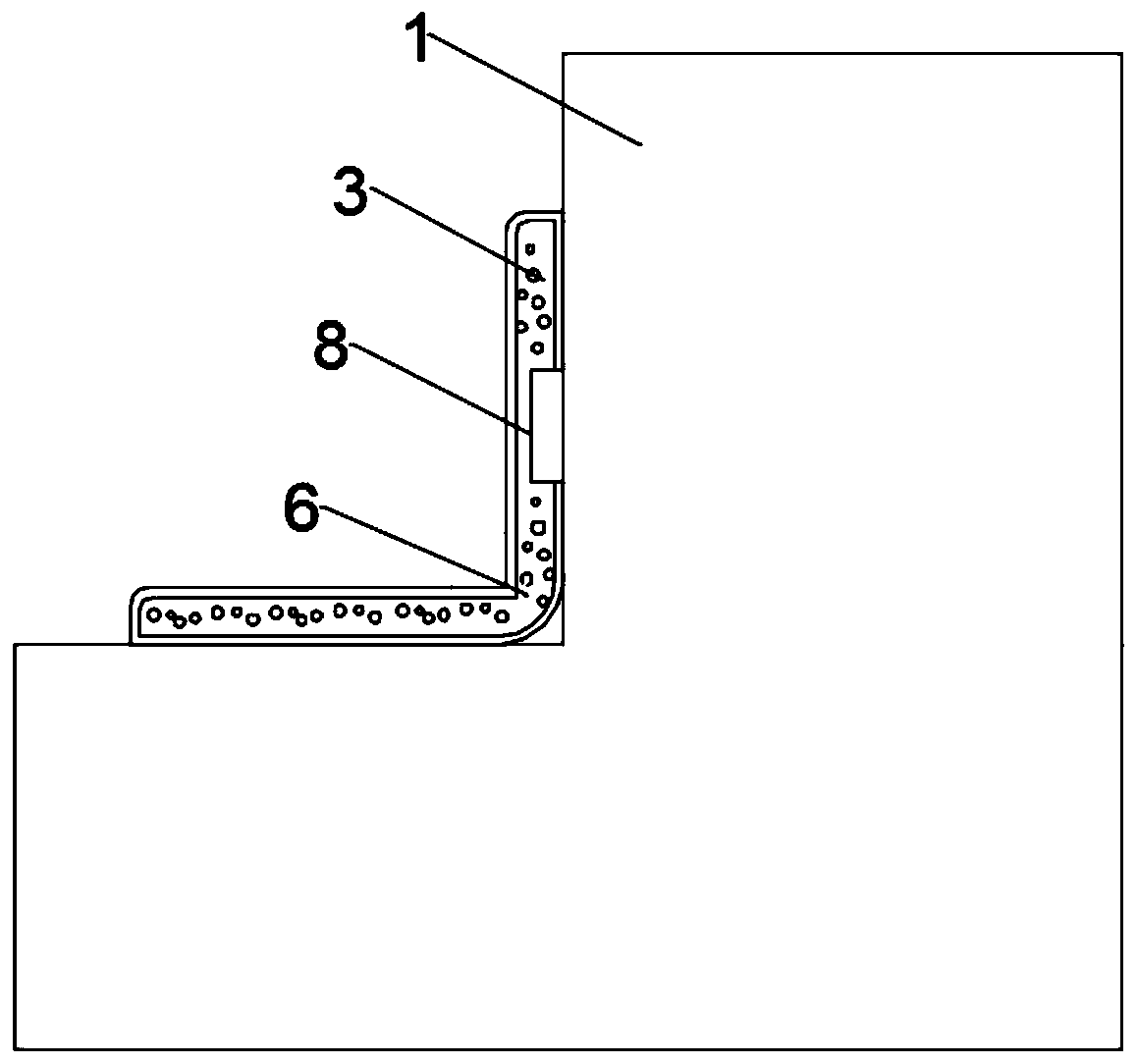

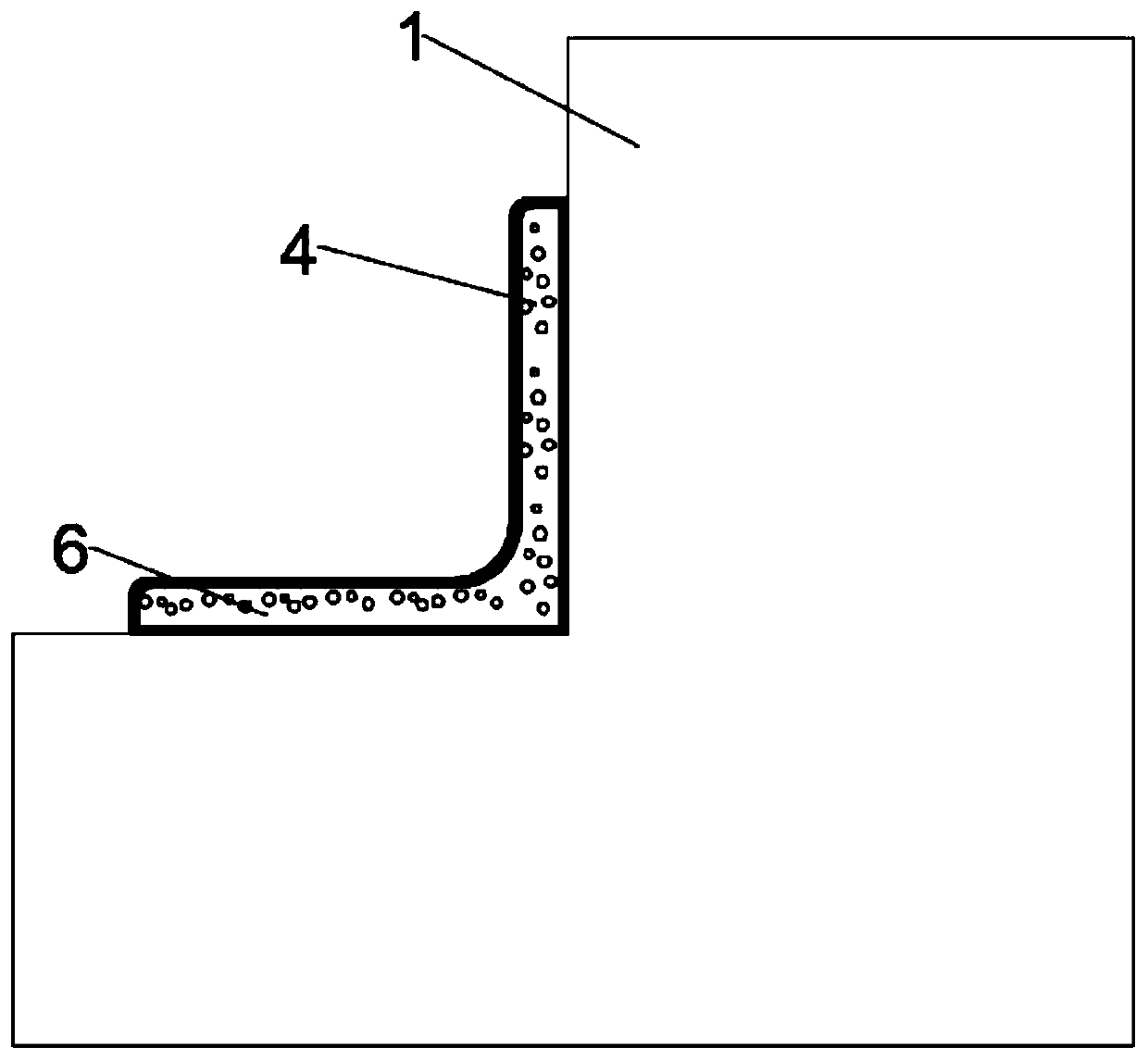

[0024] Depend on Figure 1~4 As shown, in the embodiment of the present invention, a light-weight concrete internal and external corner structure in a prefabricated building includes a wall body 1, an internal wall internal corner 2, an internal wall internal corner 3, an external wall external corner 4 and an external wall internal angle 5 , the inner wall corner 2 and the inner wall corner 3 are installed on the inner wall of the wall 1, the outer wall corner 4 and the outer wall corner 5 are installed on the outer wall of the wall 1, the inner wall corner 2, the inner corner The inner corner 3 of the wall, the outer corner 4 of the outer wall and the inner corner 5 of the outer wall are all fixed on the wall 1 through the expansion tube;

[0025] Filling area 6 is set in the inner cavity of the external corner 2 of the inner wall, the inner corner of the inner wall 3, the outer corner 4 of the outer wall and the inner corner of the outer wall 5, and the filling area 6 is fi...

Embodiment 2

[0034] A method for installing a lightweight concrete yin and yang corner structure in a prefabricated building based on the lightweight concrete yin and yang corner structure in the prefabricated building described in Embodiment 1, the steps are as follows:

[0035] S1. Fill the lightweight concrete in the filling area 6 in the mold and wait for solidification;

[0036] S2. After removing the formwork, use concrete hardener to treat the surface of the inner wall male corner 2, the inner wall female corner 3, the outer wall male corner 4 and the outer wall female corner 5 respectively to make a high-strength hard shell;

[0037] S3. During installation, the 20mm*15mm inner wall male corner wire slot 7 and the inner wall female corner wire slot are arranged on the walls at the male corner 2 of the inner wall, the female corner of the inner wall 3, the male corner 4 of the outer wall, and the female corner 5 of the outer wall. 8. After the wires are laid, cover the wire slot cov...

Embodiment 3

[0040] A prefabricated building wall, comprising the light-weight concrete yin and yang corner structures in the prefabricated building described in Example 1 and Example 2.

[0041] To sum up, the beneficial effects of the present invention are: the present invention has the advantages of energy saving, environmental protection, non-toxic and harmless, and can protect the electric wires in the room, avoiding the difficulty of overhauling the pre-embedded electric wires in the hidden piping, and exposing the open distribution wires to the outside The phenomenon that the service life of the wires is shortened, and the installation method is easy to operate, which is conducive to the promotion and use in prefabricated buildings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com