Steel circular tube single-column universal multi-dimensional special-shaped curtain wall construction structure and method

A construction method and multi-dimensional technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as short construction period, achieve the effect of ensuring the progress and quality of the project, simplifying the work process, and improving the construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

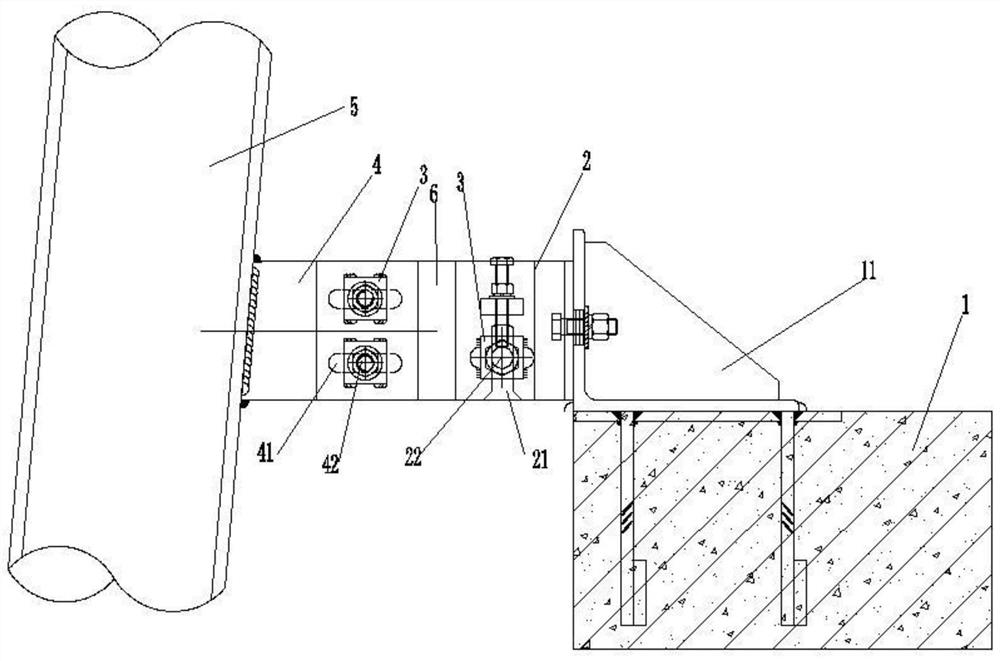

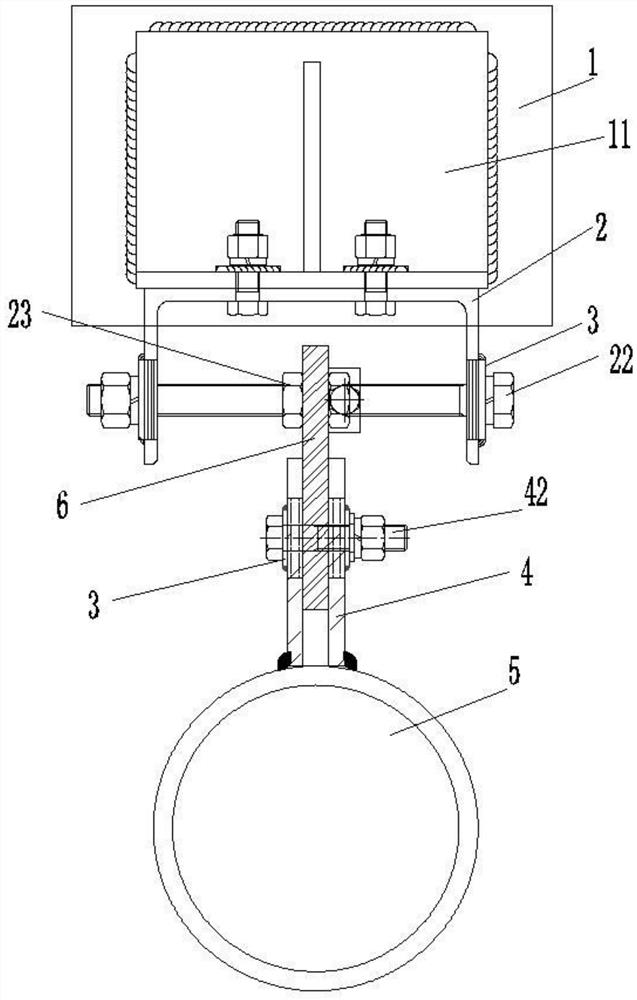

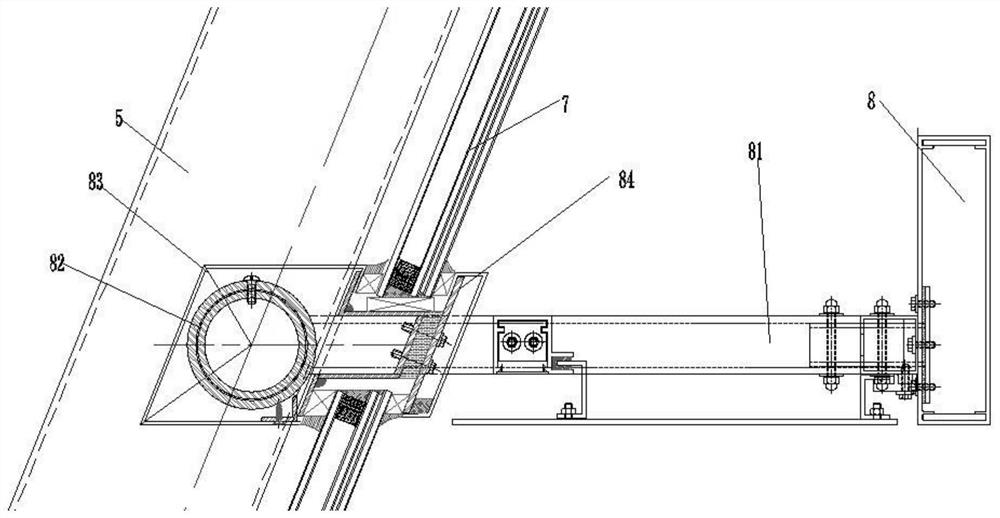

[0027] refer to Figure 1-4 As shown, a steel circular tube single-column universal multi-dimensional special-shaped curtain wall construction method, including

[0028] Step 1. Before the construction of the main structure of the civil works, import the drawings of the main structure of the civil works into the BIM 3D software for parametric modeling to obtain the BIM model;

[0029] Step 2: Based on the BIM model, obtain the multi-dimensional special-shaped curtain wall skin, keel, and connectors that are compatible with the main civil structure;

[0030] Step 3: Divide the multi-dimensional special-shaped curtain wall skin into several multi-dimensional special-shaped curtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com