Automatic piece coating machine

An automatic wrapping machine, swing arm technology, applied in sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve the problems of operator health impact, low efficiency, poor wrapping quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

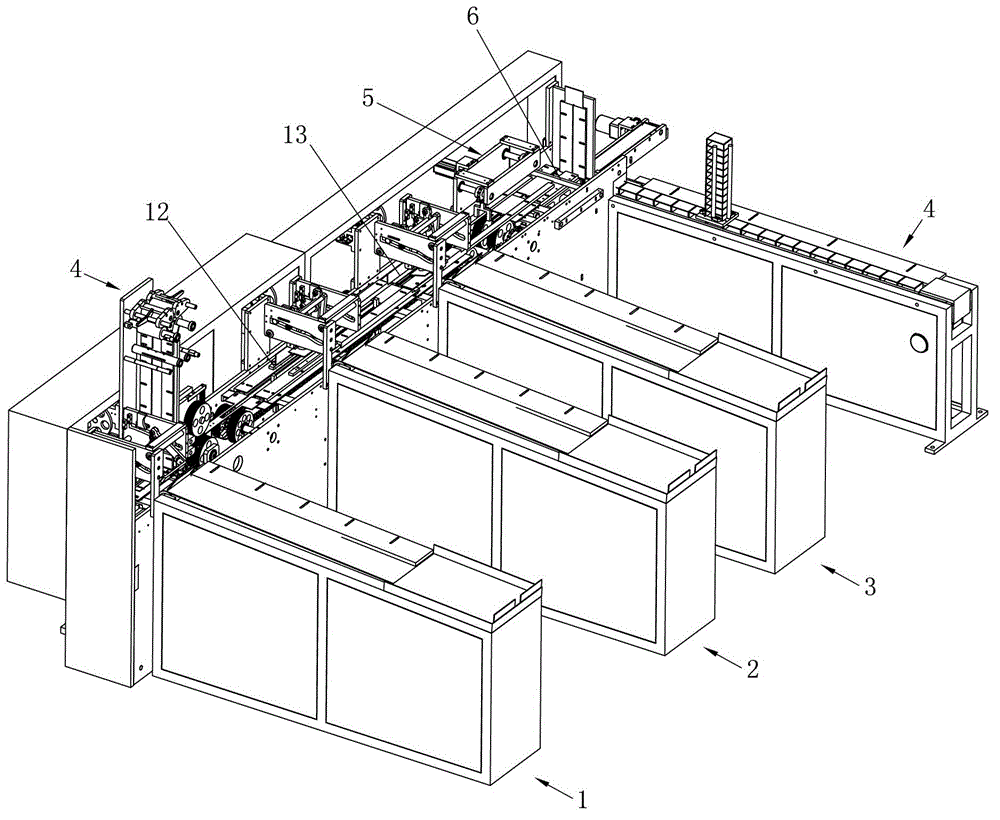

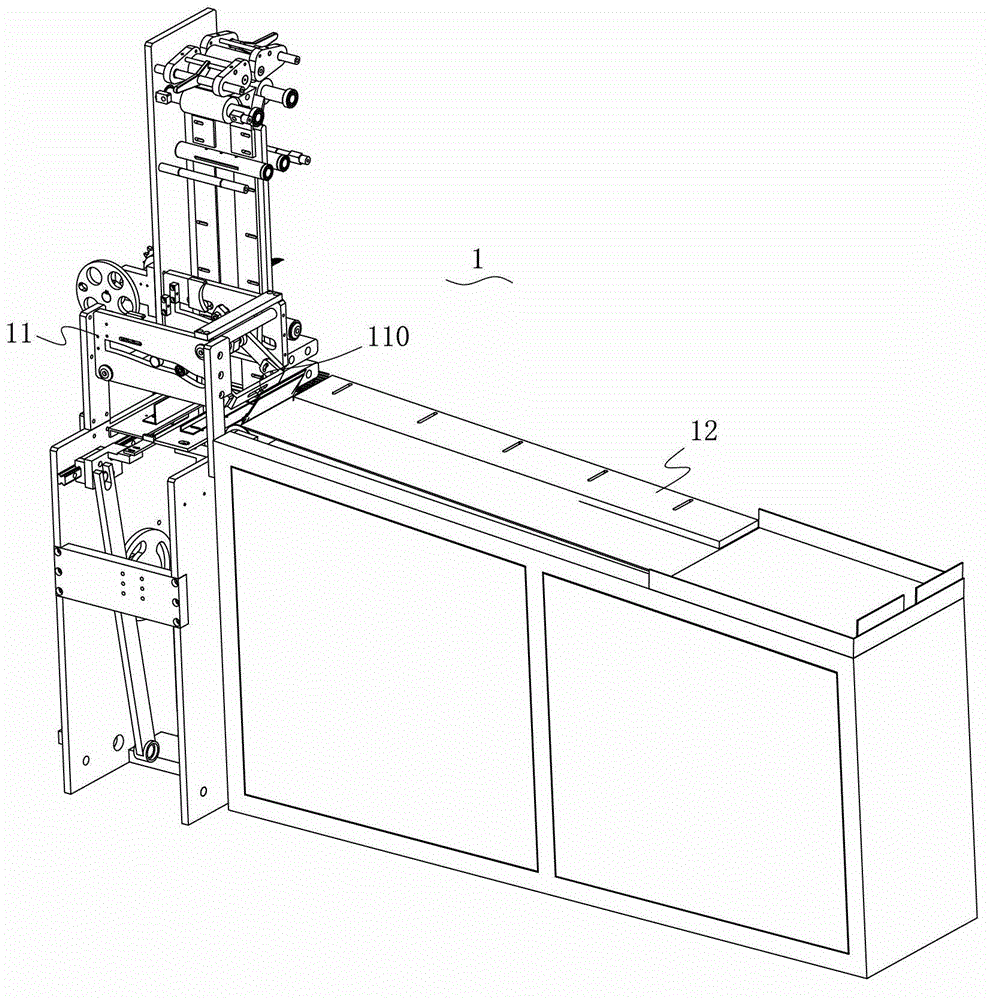

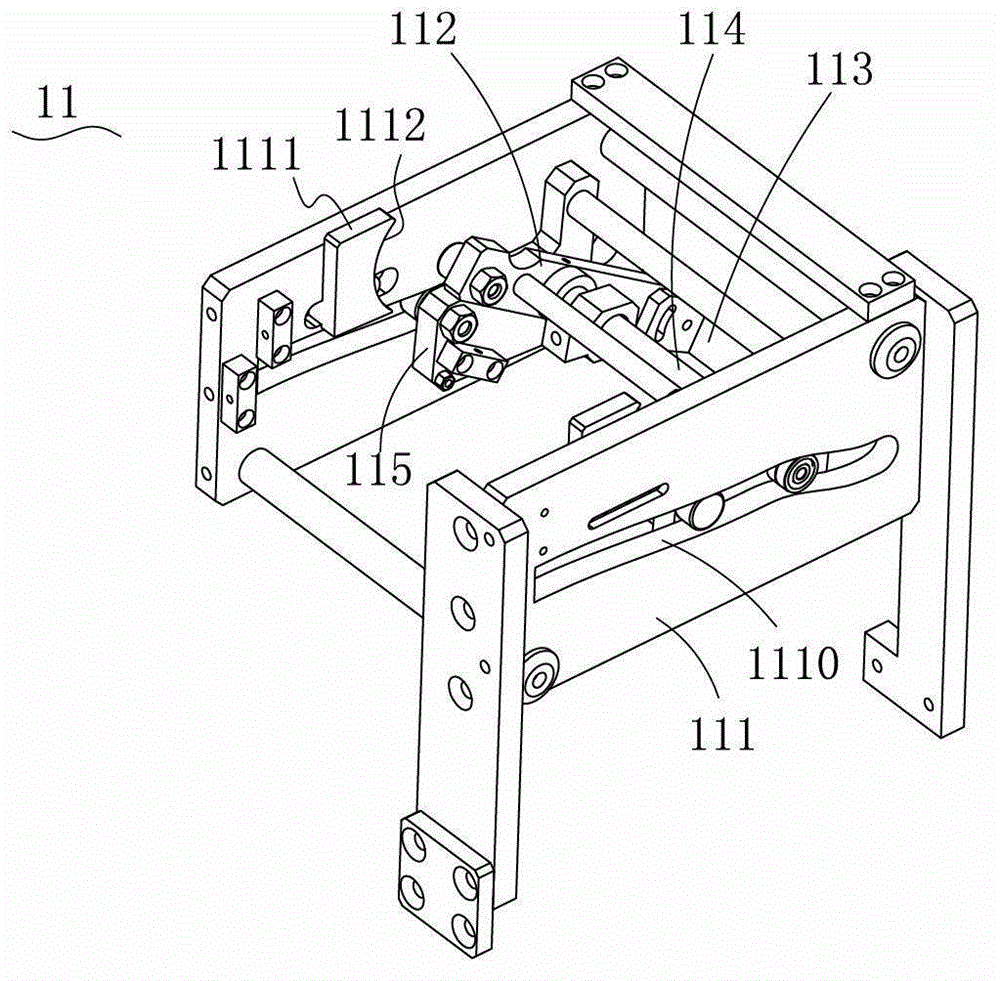

[0030] An automatic bagging machine provided by the present invention comprises a board feeding track, on which a first feeding station, a paper feeding station, a second feeding station, and a feeding station are sequentially arranged along the board feeding direction. position, material shifting device and limit block, a lifting mechanism is provided under the limit block, a material receiving plate supporting the pole plate is provided on the lifting mechanism, a box loading mechanism is provided at one end of the material receiving plate and a The box-loading mechanism transports the box-feeding mechanism of the battery box, and the box-loading mechanism is provided with a supporting plate connected with a material receiving plate. The polar plate sent out by the first feeding station is wrapped on the paper feeding station, and the wrapped polar plate is superimposed on the other polar plate on the second feeding station. Under the action, it is straightened and dropped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com