Wrapping assembly mechanism of storage battery wrapper

A technology of assembling mechanism and wrapping machine, applied in electrode manufacturing and other directions, can solve the problems of influence, poor wrapping quality, low efficiency, etc., and achieve the effect of compact overall structure, reasonable structural design, and reducing the chance of contacting the electrode plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

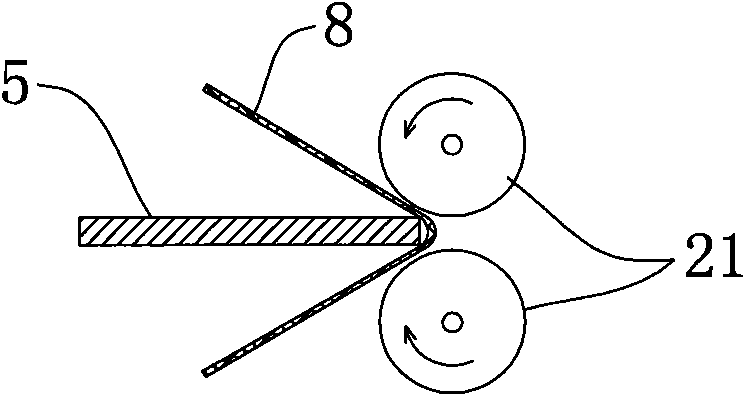

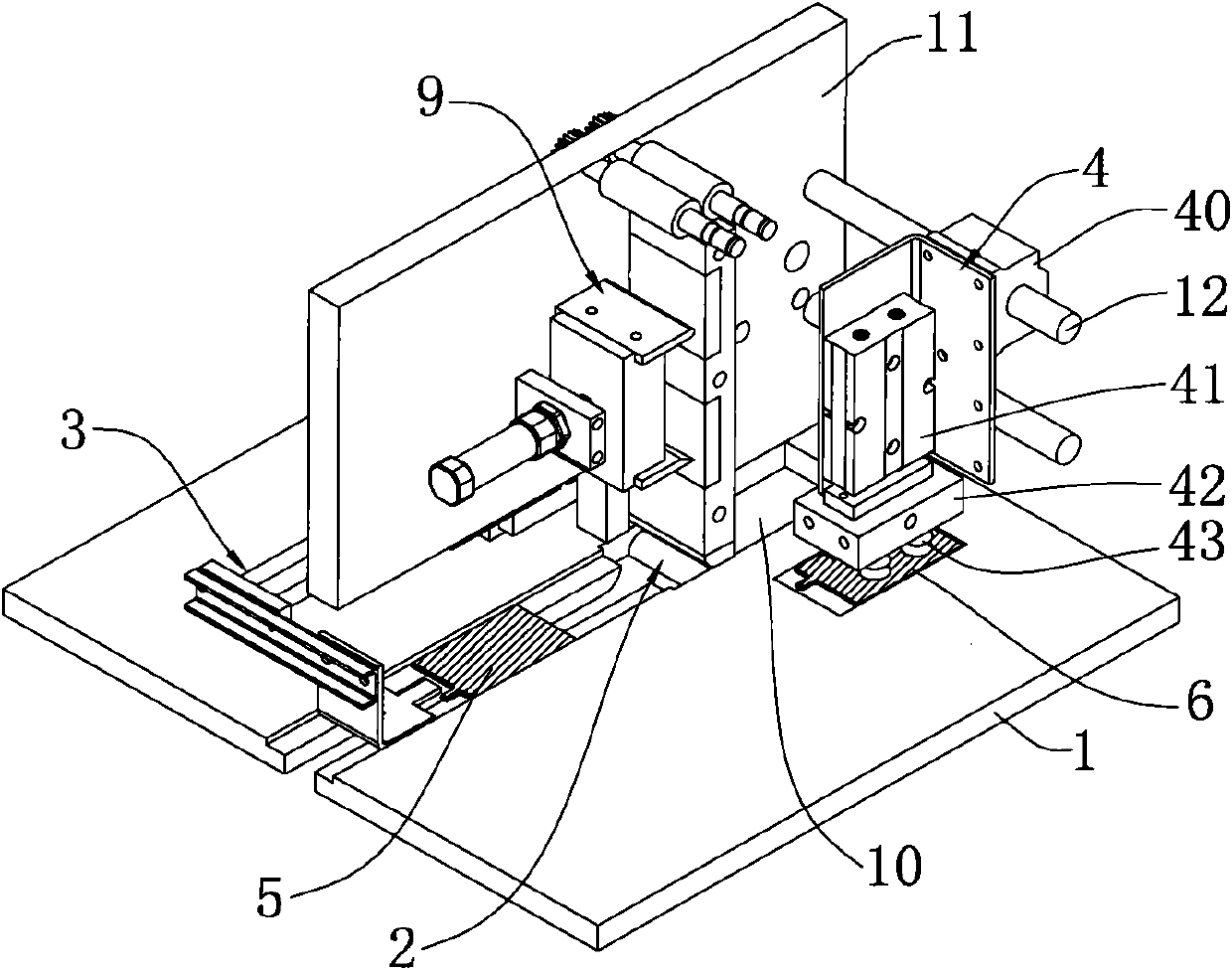

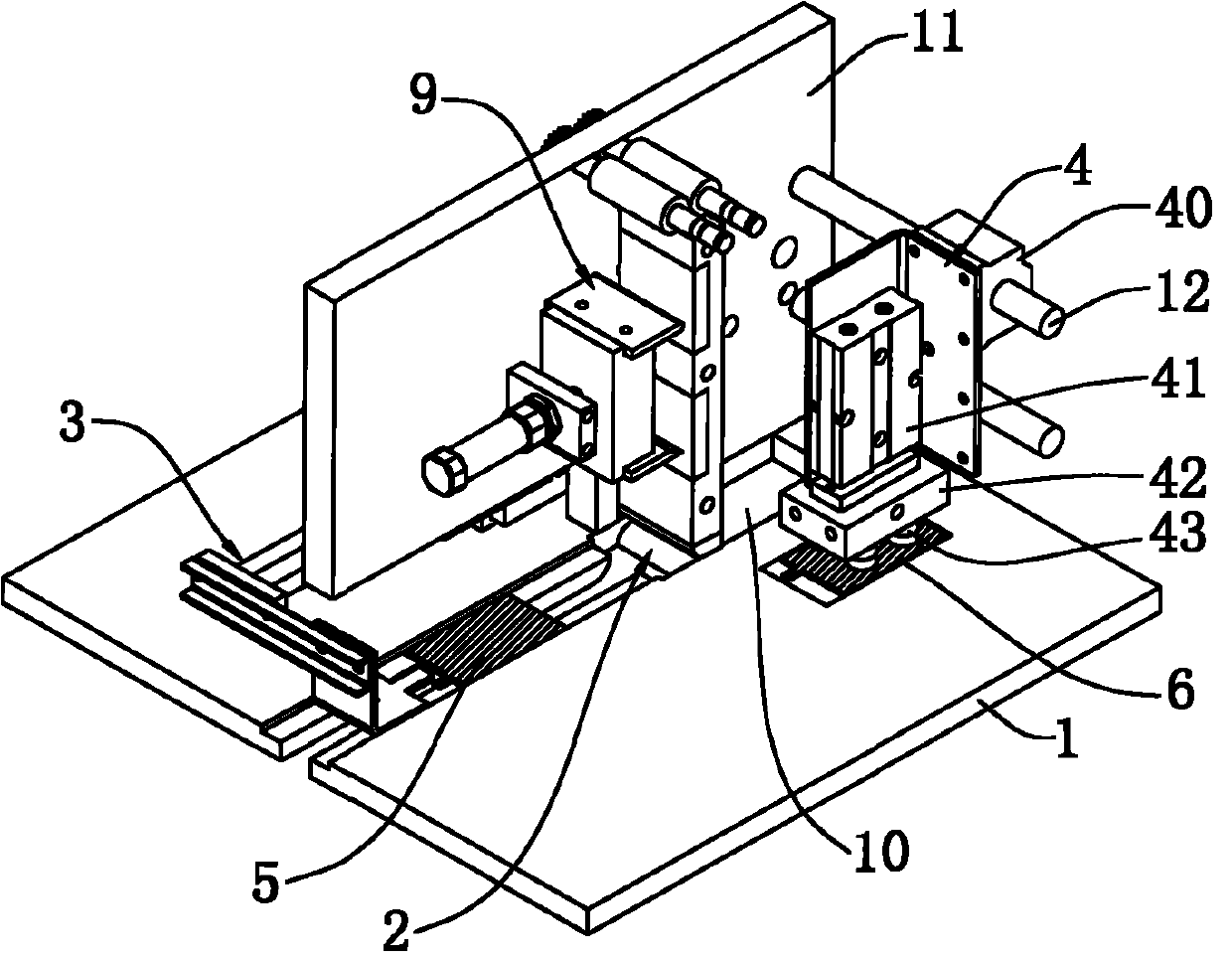

[0020] Such as Figure 1 to Figure 4 As shown, the present invention is a wrapping assembly mechanism of a battery wrapping machine, including a wrapping device for wrapping the first pole plate 5, an assembly mechanism connected to the discharge end of the wrapping device, and transporting the first pole plate to the assembly mechanism. The sheet-feeding mechanism 4 of the dipole plate 6; the sheet-wrapping device includes a sheet-wrapping part 2, a sheet-pushing mechanism 3 that pushes the first pole plate 5 to the sheet-wrapping part 2 feed openings and conveys a partition to the sheet-wrapping part 2 feed openings The paper feeding mechanism 9 of the cardboard; the assembly mechanism is an assembly box 7 connected below the outlet of the wrapping part 2, and the top of the assembly box 7 is provided with an electrode plate inlet 71.

[0021] In this embodiment, the film wrapping device, assembly mechanism and film feeding mechanism 4 are arranged in the frame assembly comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com