Full-automatic laser carving machine

A laser engraving machine, fully automatic technology, applied in the direction of engraving, decorative arts, processing models, etc., can solve the problems of the impact of the one-time pass rate of parts, increase the chance of manual contact with the parts, and low work efficiency, so as to improve the one-time pass rate, Reduce the chance of manual contact with parts and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

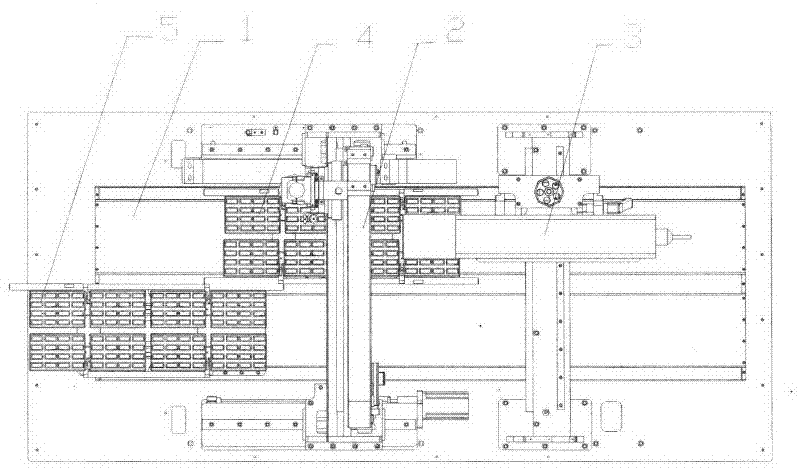

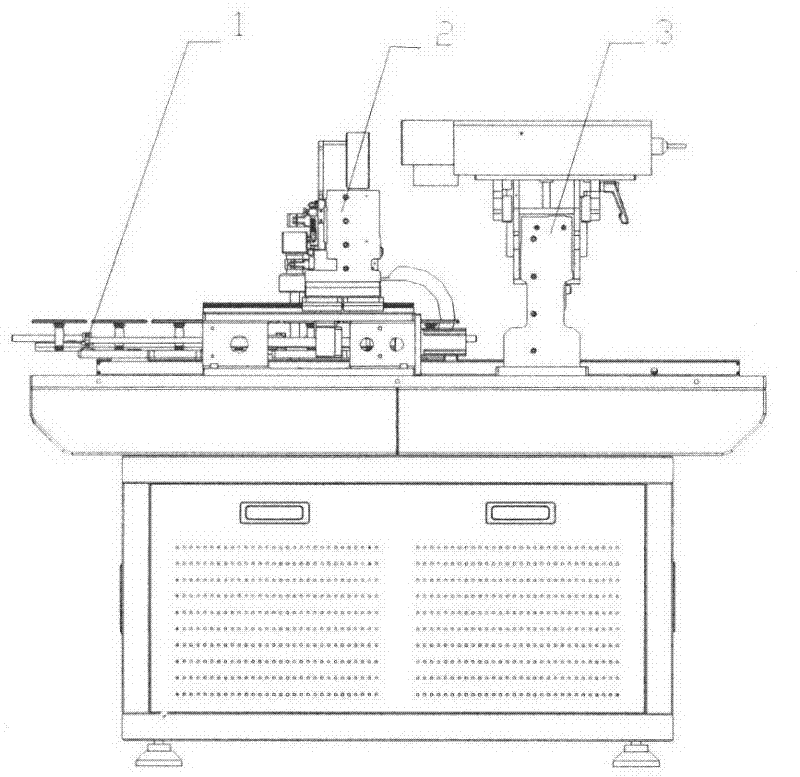

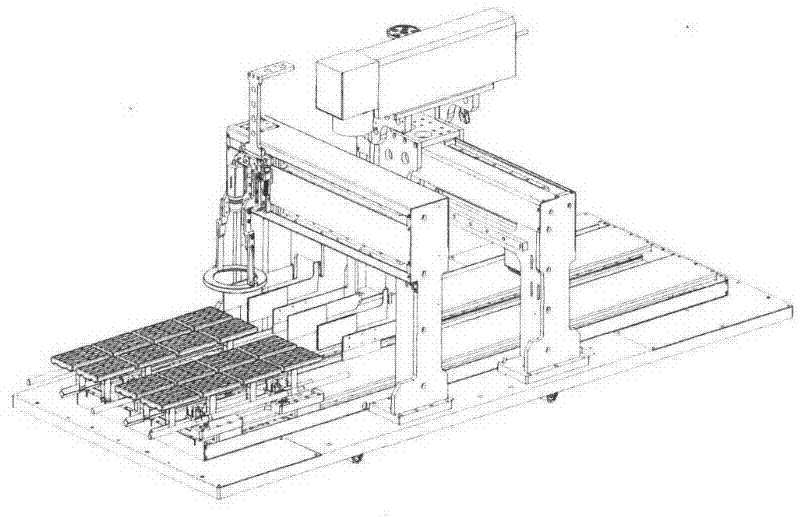

[0020] The present invention provides a fully automatic laser engraving machine. As shown in the figure, a fully automatic laser engraving machine includes a workbench 1, a visual positioning system 2, and a laser engraving machine system 3. The workbench 1 includes a material carrier A4 and Material carrier B5, the two material carriers are close to the workbench motion guide rail 8 and connected to the workbench 1, the visual positioning system 2 moves between the material carrier A4 and the material carrier B5 through the visual positioning system motion guide rail 6, laser engraving The machine system 3 moves between the material carrier A4 and the material carrier B5 through the laser engraving machine system motion guide rail 7. The laser engraving machine system 3 engraves the parts of the material carrier A4, and the visual positioning system 2 can move to the material carrier. On platform B, take pictures of the parts on material carrier B5.

[0021] The movement guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com