Robot and grabbing mechanism

A technology of grabbing mechanism and pick-up needle, which is applied in packaging and other directions, can solve problems such as labor waste, failure to meet grabbing requirements, food hygiene and safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

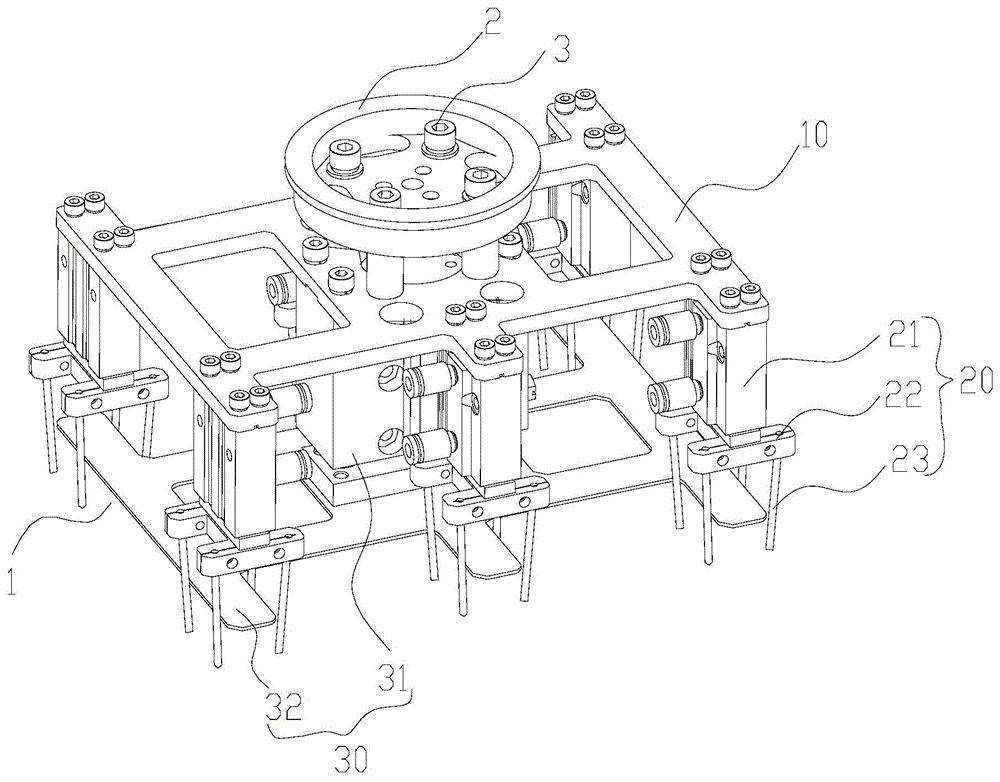

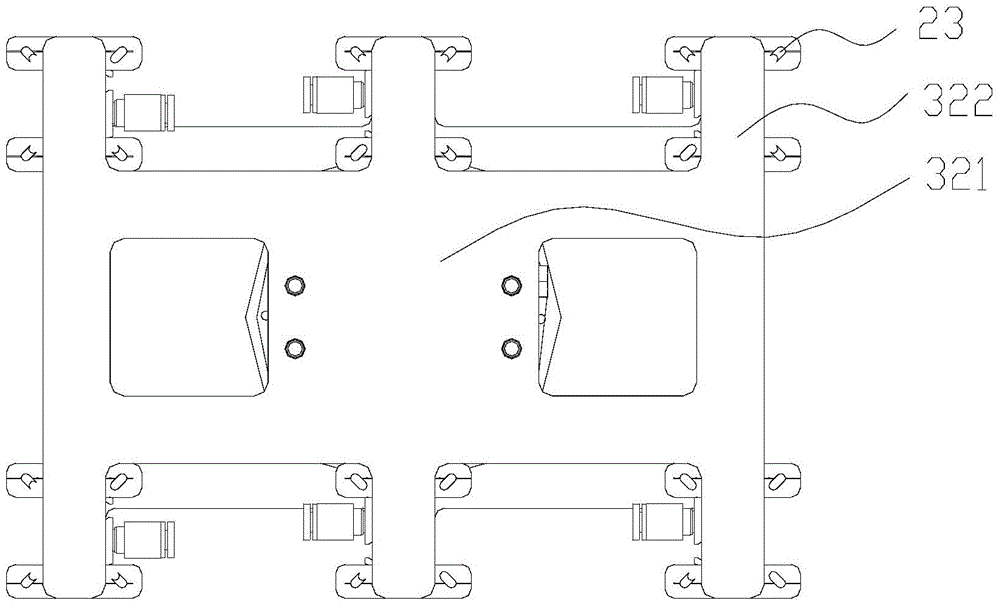

[0022] Such as figure 1 , figure 2 As shown, a grabbing mechanism 1 includes a cylinder block 10, a material retrieving assembly 20, and a discharging assembly 30. The retrieving assembly 20 includes a retrieving cylinder 21, a mounting plate 22, and at least two retrieving needles 23. The reclaiming cylinder 21 is fixed on the cylinder base 10, the mounting plate 22 is arranged on the piston rod of the reclaiming cylinder 21, the mounting plate 22 is provided with at least two mounting holes, and the retrieving needle 23 It is arranged in the installation hole, and the pick-up needle 23 is arranged obliquely relative to the vertical direction. The discharge assembly 30 includes a discharge cylinder 31 and a discharge plate 32. The discharge cylinder 31 is fixed on the cylinder On the seat 10, the discharge plate 32 is fixed on the piston rod of the discharge cylinder 31, the discharge plate 32 is arranged between two of the taking needles 23, and the discharge plate 32 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com