Sausage loading and cutting device

A sausage, No. 1 technology, applied in the field of sausage production, can solve the problems of low manual operation efficiency, unhealthy people, long waiting time, etc., and achieve the effect of improving the economic benefits of businesses, reducing manual contact, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

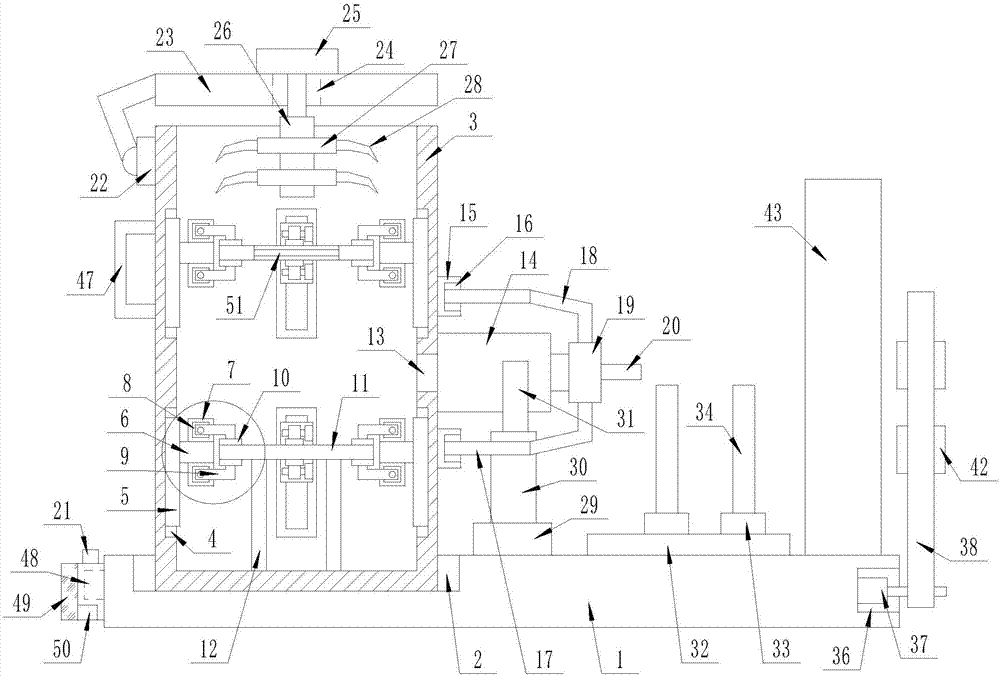

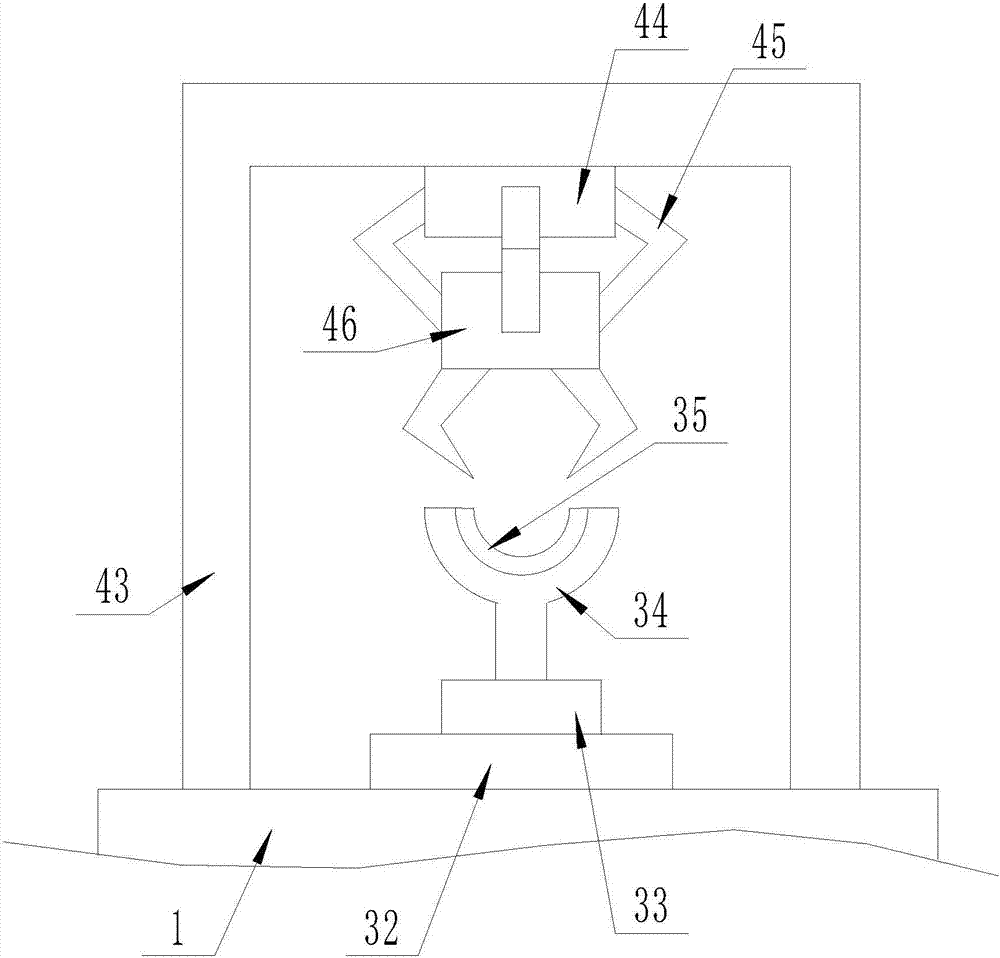

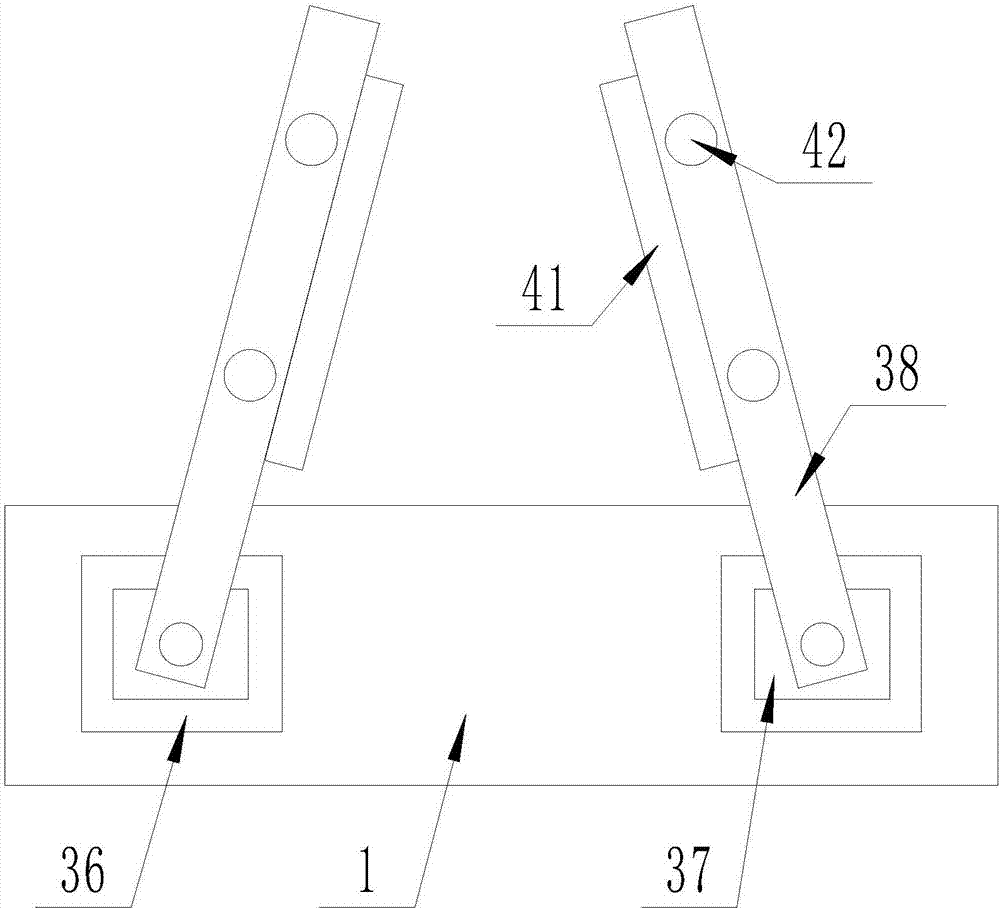

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown, a sausage filling and cutting device includes a bar-shaped base (1), the upper surface of the bar-shaped base (1) has a No. 1 circular groove (2), and the No. 1 round The groove (2) is embedded with a circular raw material mixing bucket (3), and the upper surface of the strip base (1) is fixedly connected with a support mechanism on the right side of the No. 1 circular groove (2). The upper surface of the bar-shaped base (1) and the right side of the filling mechanism are provided with a fixed-length snap mechanism, and the side surface of the bar-shaped base (1) is provided with a cutting mechanism overlapping with the fixed-length snap mechanism , the circular raw material mixing barrel (3) is provided with an extrusion filling mechanism, and the side surface of the circular raw material mixing barrel (3) is provided with a rotating stirring mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com