Plastic bag packer

A packaging machine, plastic bag technology, applied in packaging, transportation packaging, paper product packaging and other directions, can solve the problems of packaging bag adhesion, complex movements, fast packaging speed of plastic bag packaging machines, etc., to ensure length accuracy and stable work. Reliable, stable and reliable bag making effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

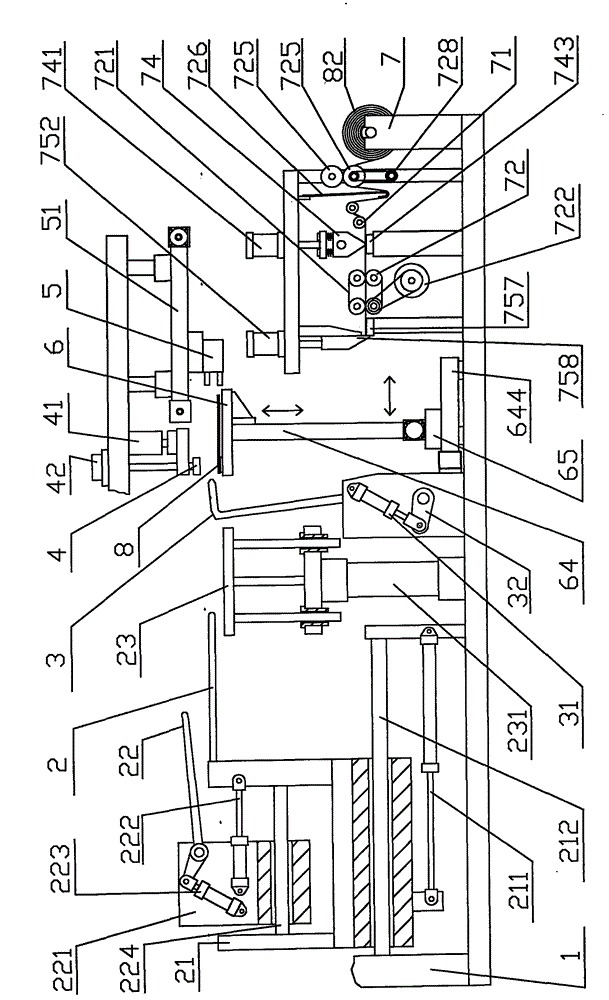

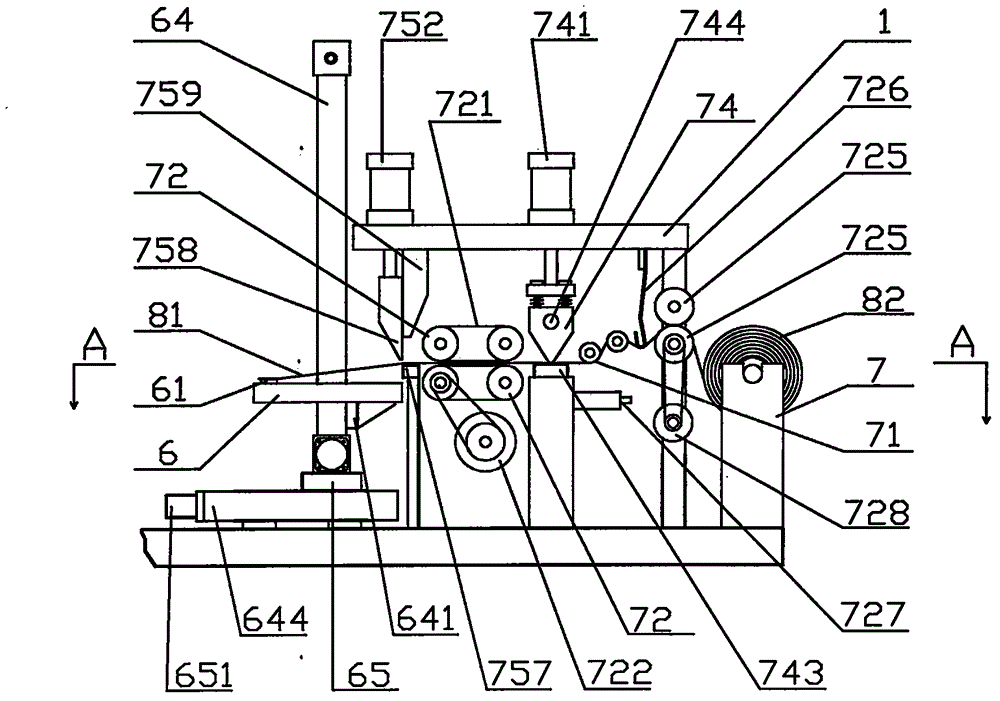

[0045] Example 1: Please refer to figure 1 , figure 2 , image 3 . On the lower frame 1 corresponding to the suction cup 4, the electric slide table 644 is installed front and rear, on the slide table 65 of the electric slide table, two linear modules 64 are erected left and right, and the two synchronous wheels below the two modules 64 are connected to the transmission shaft. 643, one end of the drive shaft 643 is connected to the module motor 642, a bracket 611 is installed on the two slide blocks 641 of the two modules 64, and the storage bag tray 6 is installed on the bracket 611; on the front side of the storage bag tray 6 Suction nozzle 61 is installed in the position corresponding up and down with lifting suction cup 4 in the middle, and suction nozzle 61 communicates with suction fan 62 with pipeline 63, as Figure 8 shown. Described electric sliding table 644 and linear module 64 belong to known technology, just can buy on the market. The above embodiment is the...

Embodiment 2

[0054] Embodiment 2: The main difference between Embodiment 2 and Embodiment 1 is that: the front and rear ends of the bag storage tray 6 are provided with suction nozzles 61; Clamping manipulator etc. constitute, omitted the pre-discharging device of embodiment 1; Cutting mechanism is made of cutting seat 751, rodless cylinder 753, blade 75, cutting backing plate 755, concave pressing plate 756 etc.

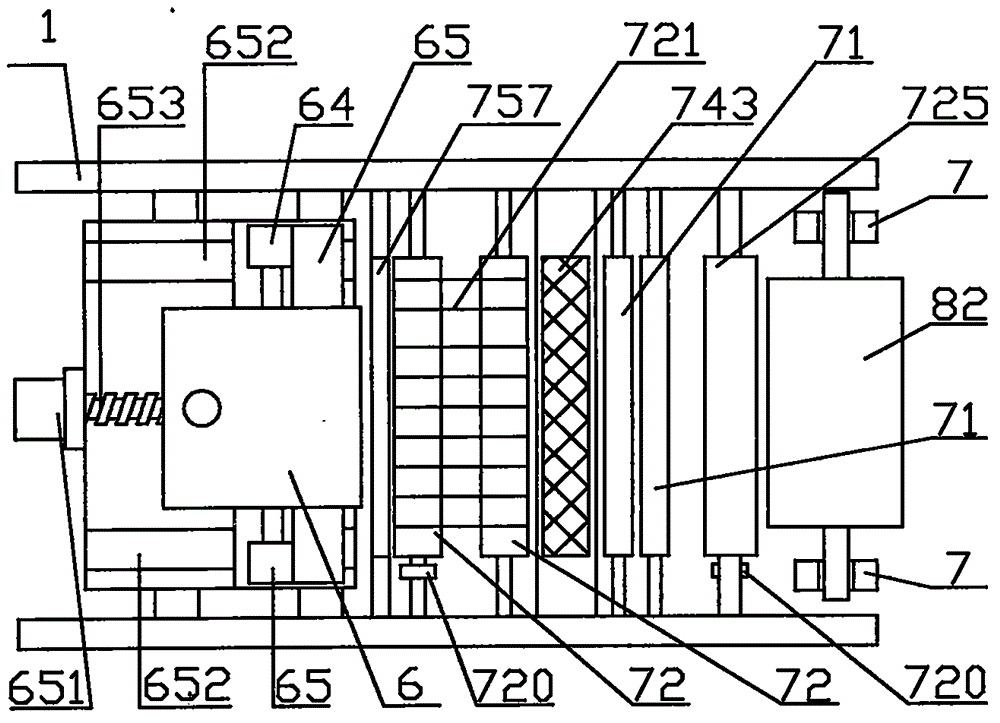

[0055] Such as Figure 12 Shown: a pressure roller 736 is installed in front of the guide roller 71, the two ends of the pressure roller 736 are respectively equipped with rocking arms, the other ends of the two rocking arms are hinged on the frame, and the guide rollers are installed on the frame below the pressure roller 736. Rod cylinder 735, lift platform 734 is installed on the guide rod cylinder 735, and pressure roller 736 also moves up and down thereupon when rising or descending. Two linear modules 731 are installed front and rear on both sides of the lower frame corre...

Embodiment 3

[0057]Embodiment 3: The difference between Embodiment 3 and Embodiment 1 is that the bag-feeding mechanism is only a set of upright sides of the lower frame corresponding to the lifting suction cup 4 up and down, and the electric slide table is omitted; A bag-making track 711 is installed between the racks, and the bag-making device is slid on the bag-making track 711 through a slider 714. A screw pair 712 is installed between the bag-making device and the frame 1, and the packaging is adjusted by turning the hand wheel 713. The optimum opening position of bag and the position of suction cup 61.

[0058] Such as Figure 16 , Figure 17 As shown: the four output rubber rollers 72 in the output mechanism of the bag making device are changed to two, and the two output rubber rollers 72 are elastically connected on the rubber roller track up and down, and are in multiple annular grooves of the two output rubber rollers 72 Conveying air pipes 729 are installed respectively, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com