Connecting rod structure and auxiliary assembling device

A technology of auxiliary assembly device and connecting rod structure, which is applied in the direction of connecting rod, workpiece clamping device, shaft installation, etc., can solve the problem that the length accuracy of the connecting rod structure is difficult to guarantee, and achieve a simple and convenient locking method, ensuring length accuracy, The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

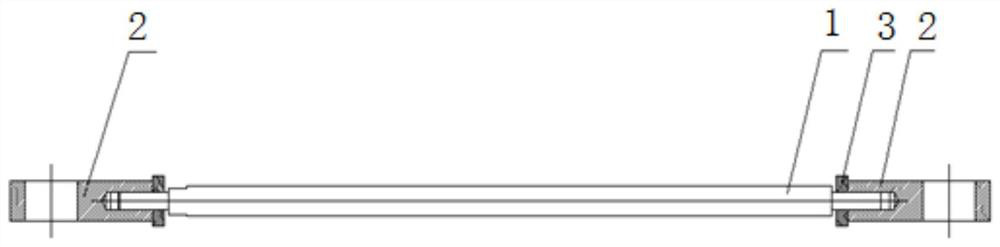

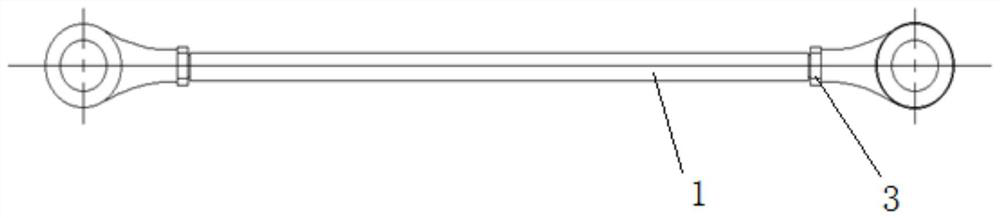

[0040] This embodiment provides a connecting rod structure, in one embodiment, such as figure 1 and figure 2 As shown, the connecting rod structure includes a straight rod 1, an adjusting rod 2 movably connected to the end of the straight rod 1, a locking member for fixing the adjusting rod 2 on the straight rod 1, and the two ends of the connecting rod structure A mounting hole is provided, the axis of the mounting hole is perpendicular to the axis of the straight rod 1, and the mounting hole is used for connecting with other structures.

[0041] The connecting rod structure provided in this embodiment can adjust the rod length of the connecting rod structure by adjusting the position of the adjusting rod 2 on the straight rod 1 by splitting the connecting rod structure into a straight rod 1 and an adjusting rod 2 to ensure that the connecting rod The length accuracy of the structure and the processing accuracy requirements for the straight rod 1 and the adjusting rod 2 can...

Embodiment 2

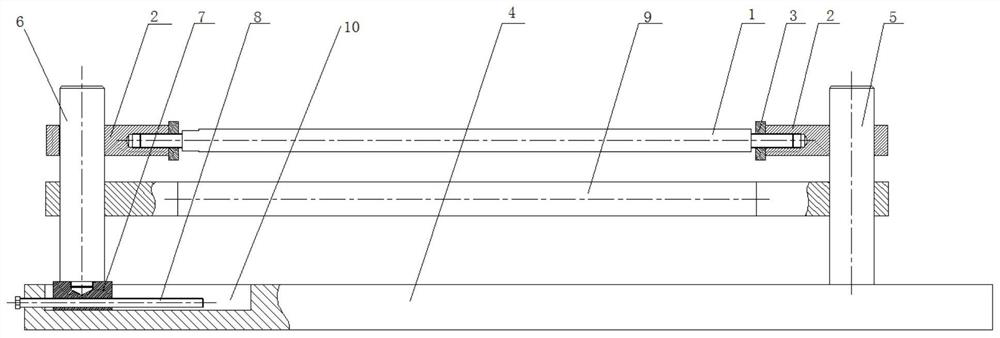

[0048] This embodiment provides an auxiliary assembly device for assembling the connecting rod structure provided in the above embodiments. In one embodiment, as image 3 and Figure 4 As shown, the auxiliary assembly device includes a fixed seat 4 and a positioning shaft.

[0049] Wherein the fixed seat 4 is a square plate. The positioning shaft is arranged on the fixing base 4, and there are two positioning shafts, and the distance between the two positioning shafts is adapted to be equal to the preset distance between the two mounting holes of the connecting rod structure.

[0050] In the auxiliary assembly device provided in this embodiment, since the distance between the two positioning shafts is equal to the preset distance between the two mounting holes of the connecting rod structure, only the distance between the two mounting holes of the connecting rod structure can be adjusted to Only when the distance between the two positioning axes is equal, the two mounting ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com