Microwire Array Electrode Production Mold

An array electrode and array module technology, which is applied in the field of micro-wire array electrode production molds, can solve the problems of difficulty in precise welding of electrode wires, poor device consistency, and difficulty in fixing positions, and achieves high yield, timely and effective fixing and adjustment. , The effect of ensuring the quality of the electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Those skilled in the art will be more aware of the above and other objects, advantages and features of the present invention according to the following detailed description of specific embodiments of the present invention in conjunction with the accompanying drawings.

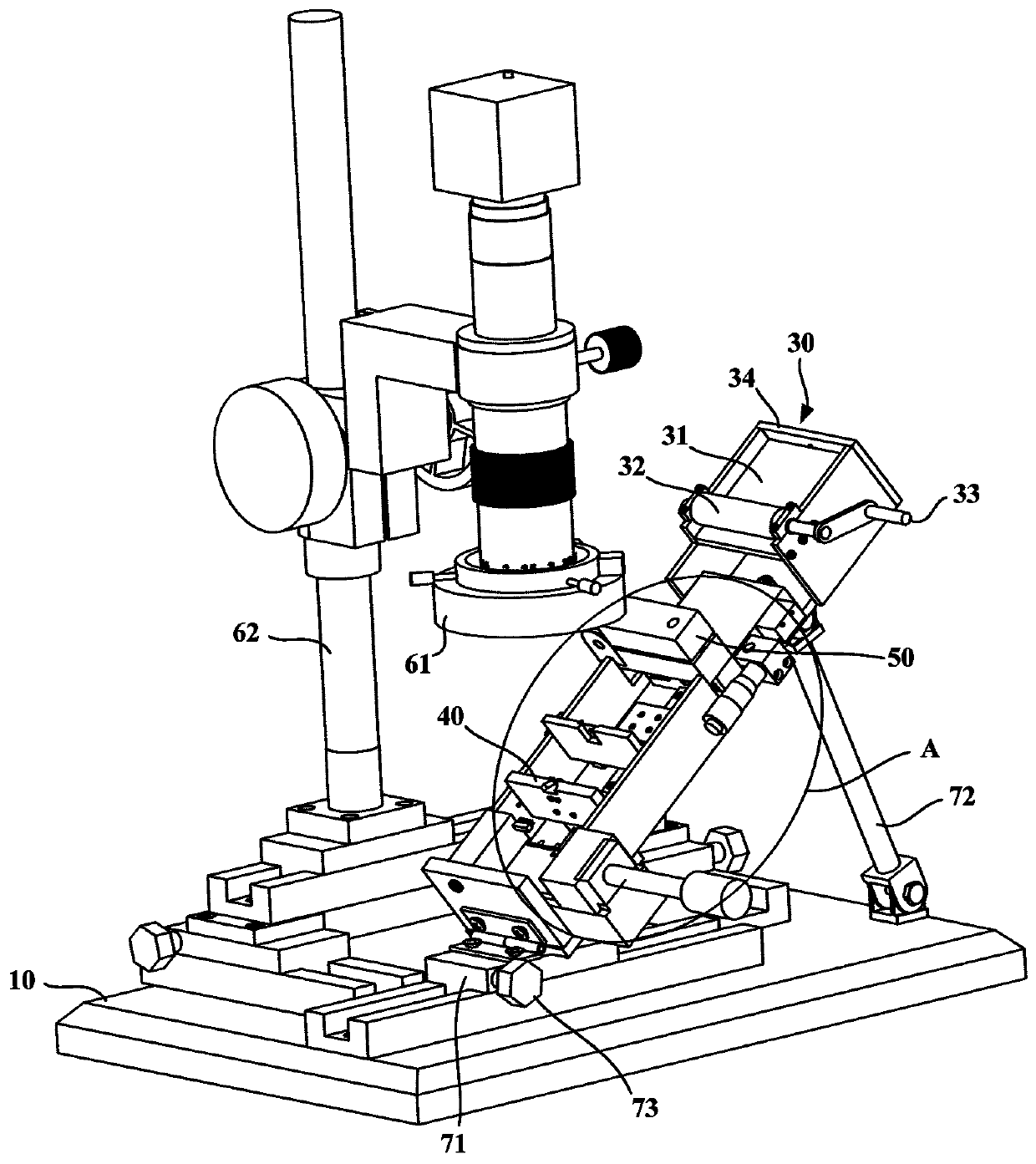

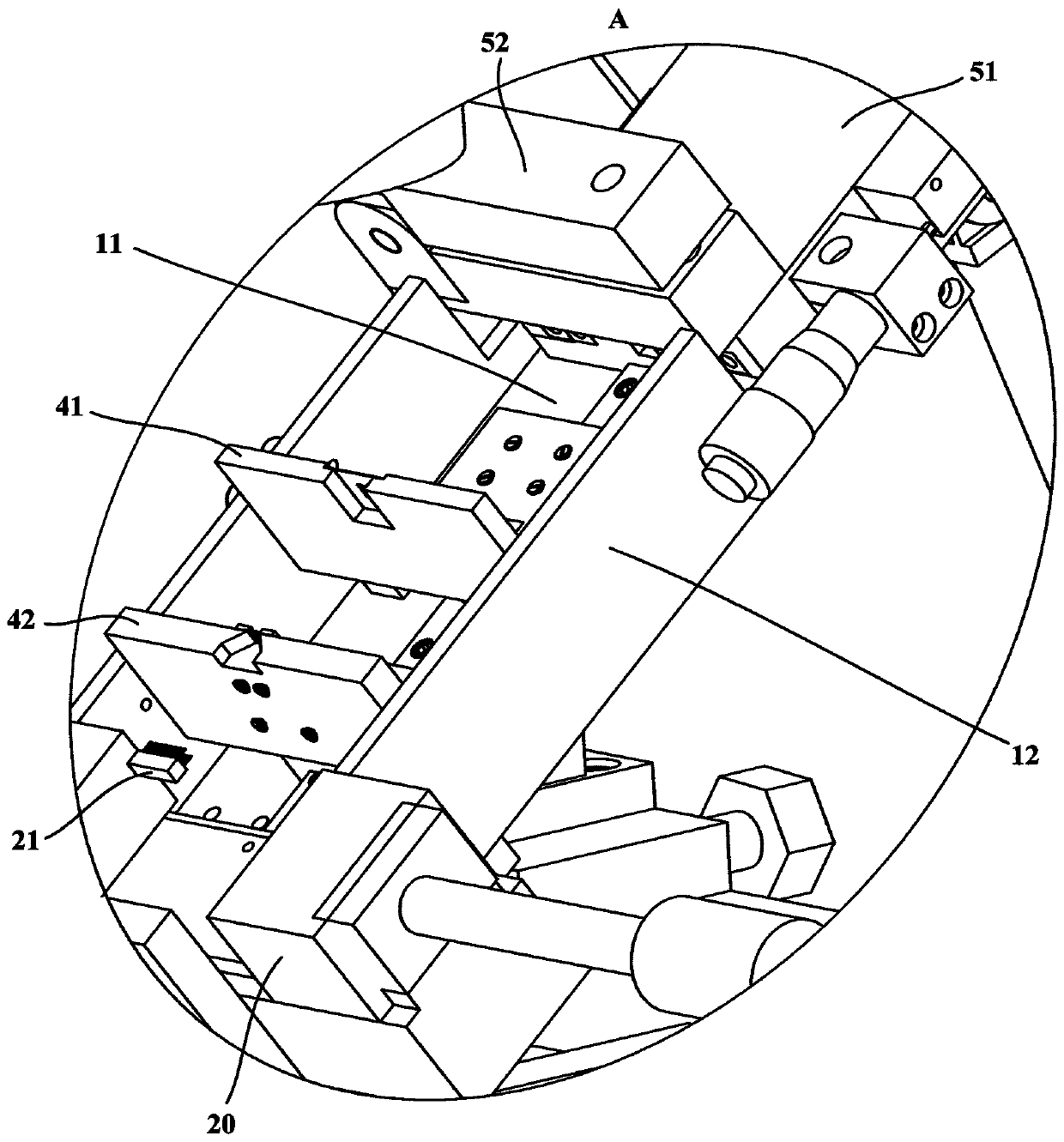

[0032] figure 1 is a schematic structural diagram of a microwire array electrode production mold according to an embodiment of the present invention; figure 2 Yes figure 1 Schematic partial enlarged view at A. like figure 1 and figure 2 As shown, the embodiment of the present invention provides a microwire array electrode production mold, which is configured to fix the electrode wire and the electrode pin header 21, so that automatic welding equipment or operators can use manual welding equipment to weld the electrode wire to the electrode pin header 21 on. The microwire array electrode production mold may include a bottom plate 11 , an electrode pin fixing device 20 , a wire feeding device 30 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com