Napkin packing machine

A packaging machine and paper towel technology, which is applied in paper product packaging, packaging, transportation packaging, etc., can solve the problems of large labor, long working hours, and secondary pollution in enterprises, and achieve reduced labor intensity, high packaging level, and improved packaging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

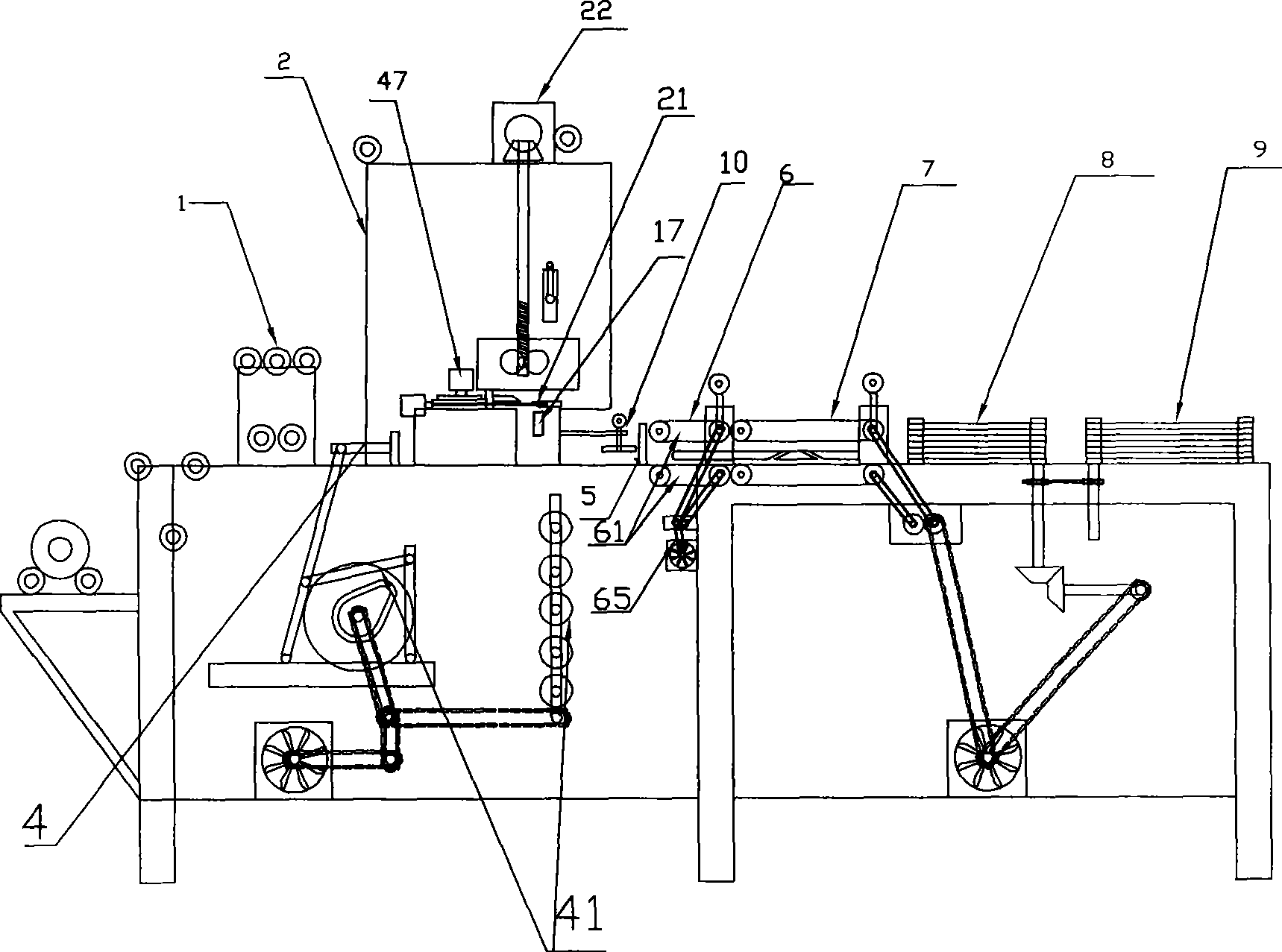

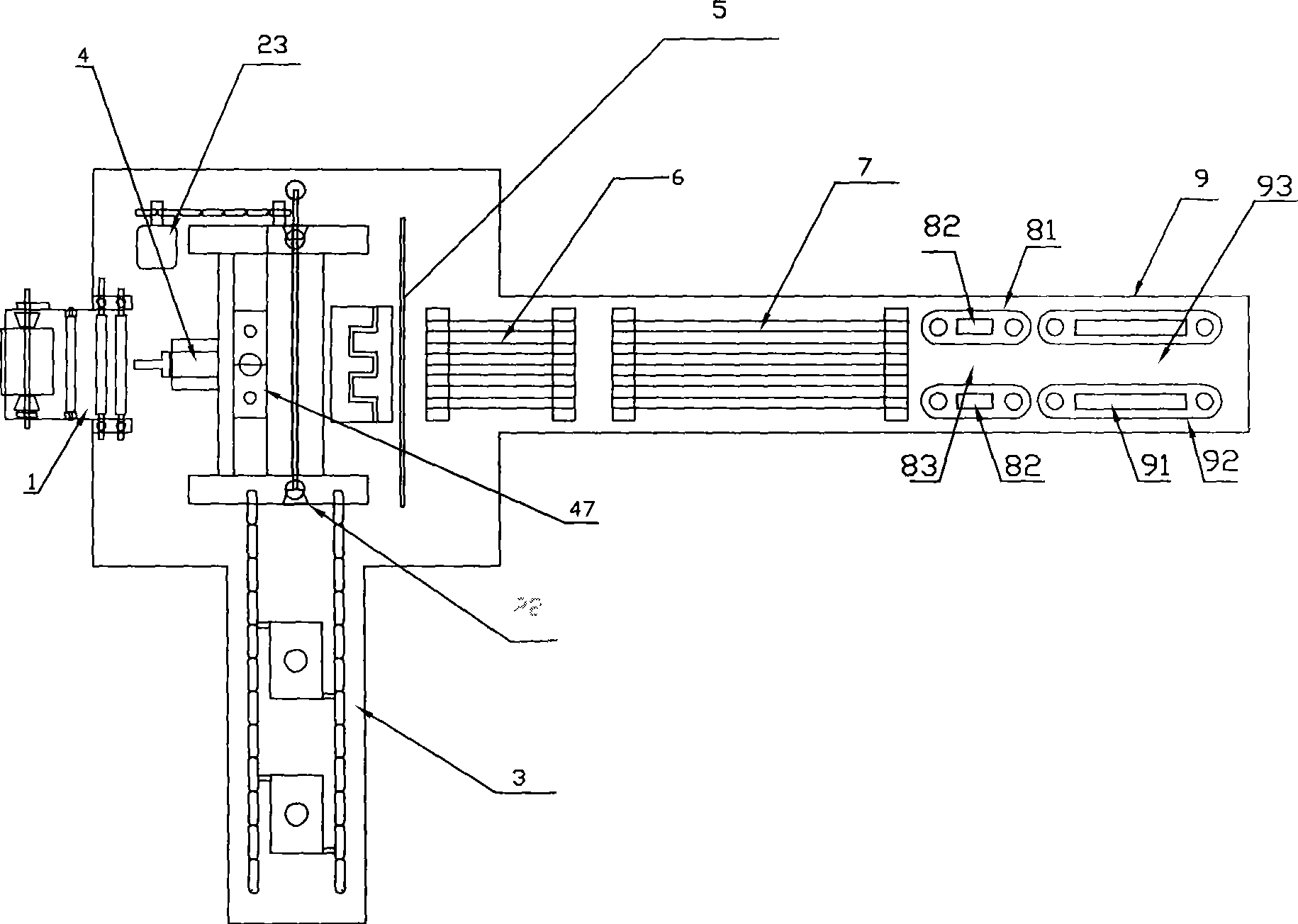

[0025] Such as figure 1 and figure 2 As shown, the rear film feeding device 1 of the tissue packaging machine of the present invention is located before the front film feeding device 2 , the front film feeding device 2 is located before the wrapping device 10 , and the vacuum film suction device 17 is below the front film feeding device 2 . The paper pushing device 4 is located at the tail end of the paper towel conveying device 3 and below the front film feeding device 2 . The side sealing device 5 , pin forming device 6 , end face forming device 7 , end face sealing device 8 and ironing device 9 are arranged after the wrapping device 10 in sequence.

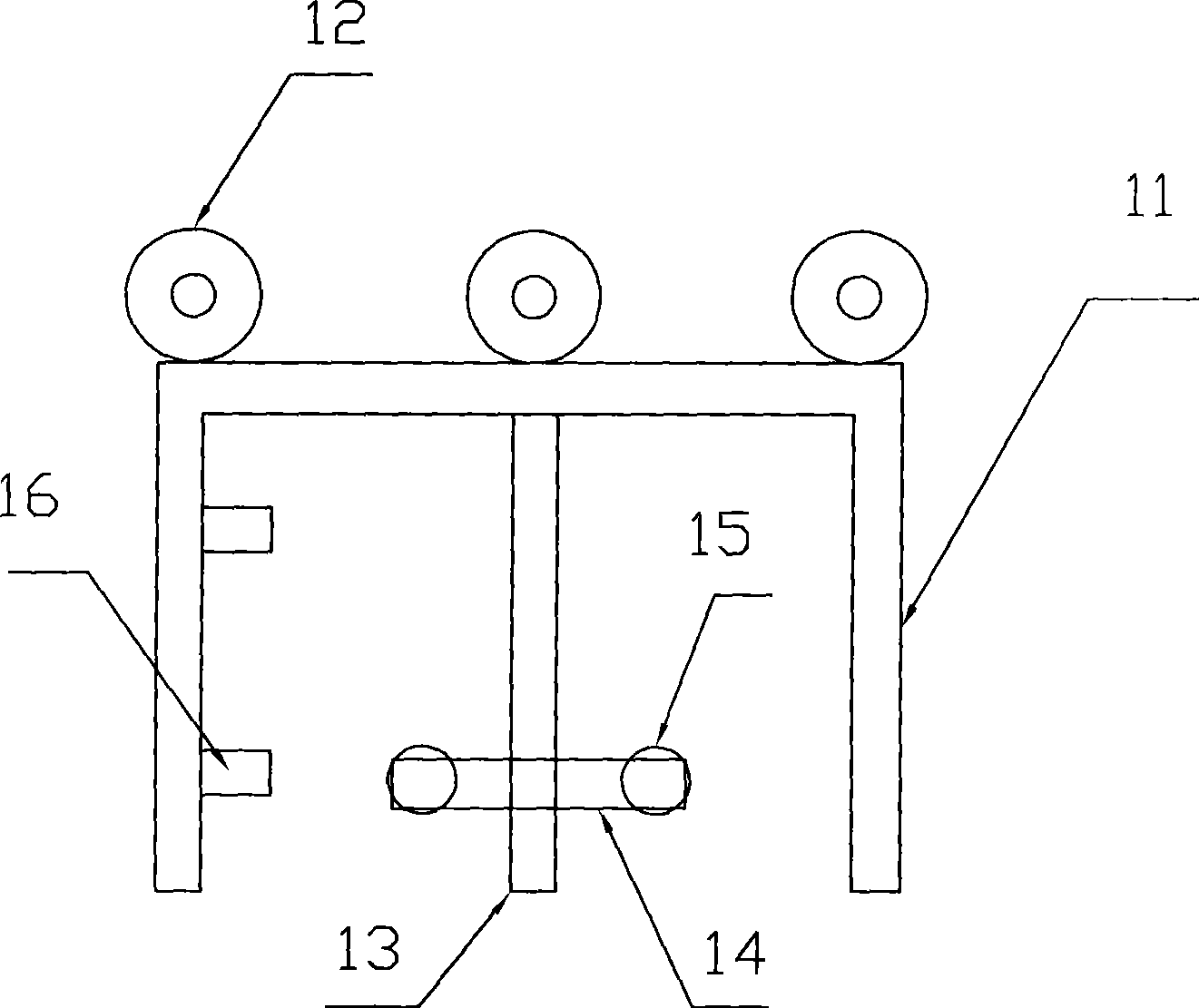

[0026] Such as image 3 As shown, the top of the film feeding positioning frame 11 of the film feeding device is equipped with a cylinder 12, and a group of sliding rods 13 are fixed in the middle of the film feeding positioning frame 11. The bottom of the sliding rod 13 is fixed with a slide plate 14, and two rollers 15 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com