Plastic body folding machine

A technology of plastic bags and folding machines, which is applied in the direction of paper product packaging, packaging, and packaging item types. It can solve the problems of tail scalding, single binding form, and high manufacturing cost, so as to achieve the goal of not being easily deformed and unraveling, ensuring the pass rate, and neatly folding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

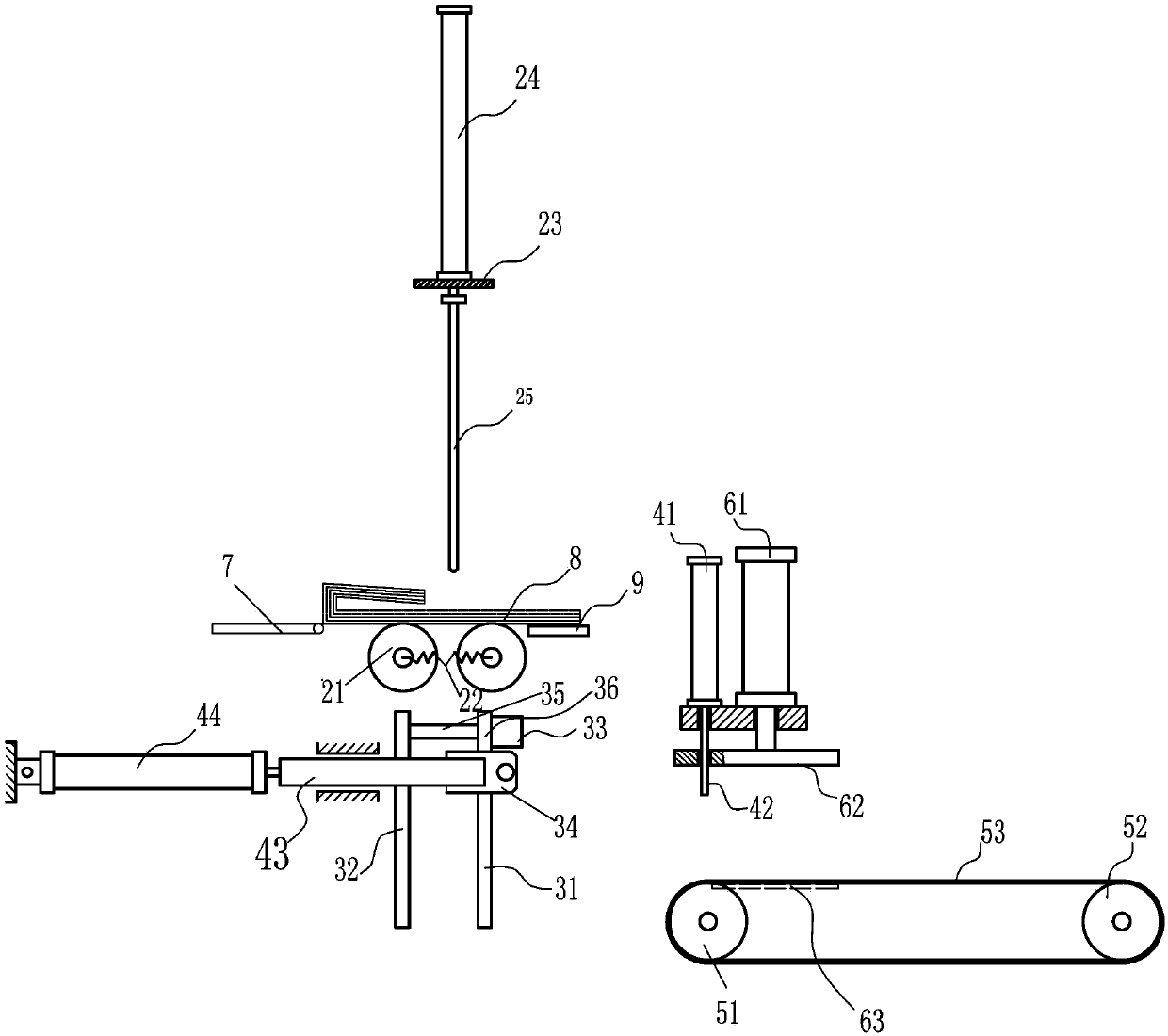

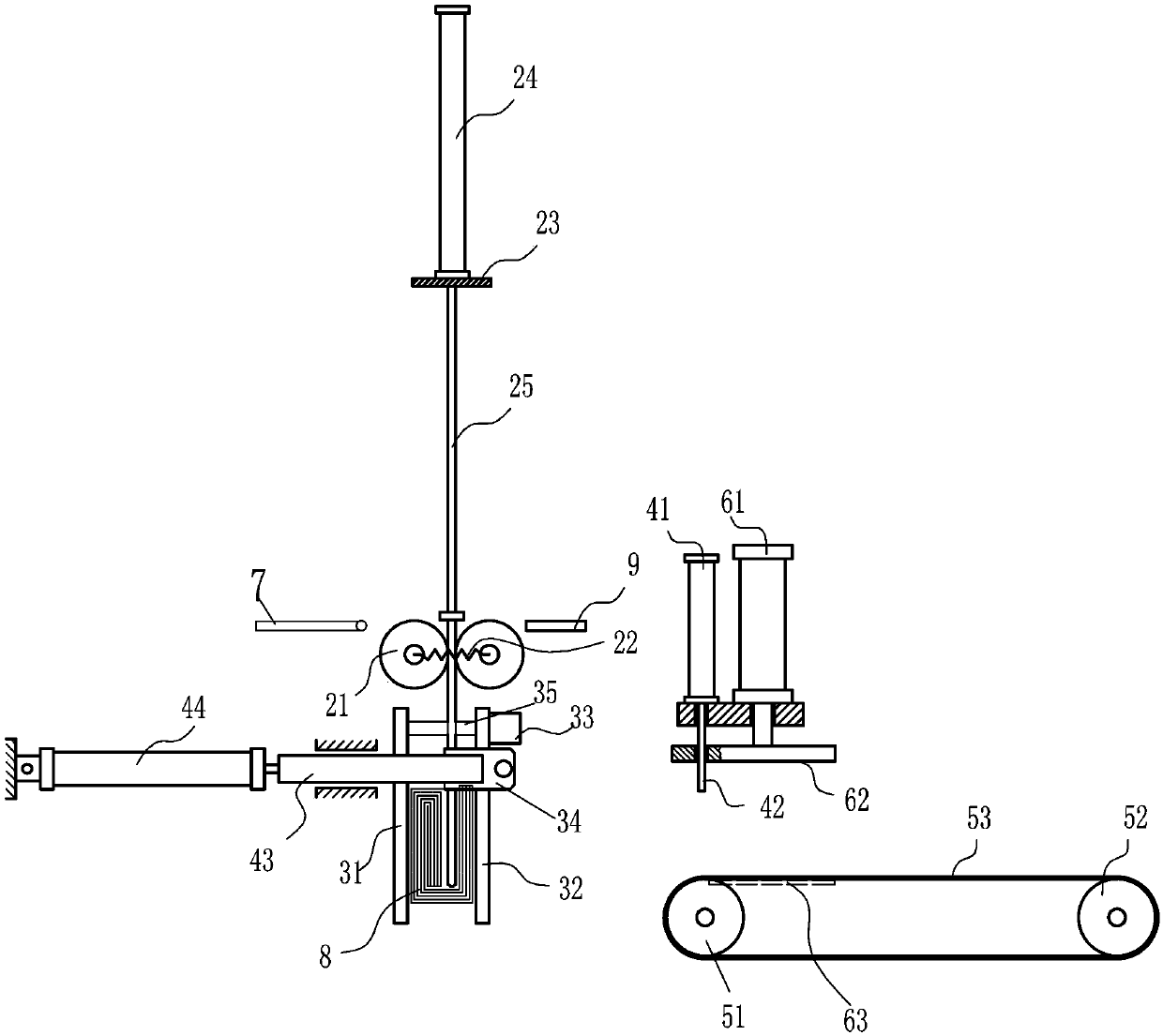

[0040] The clamping plate device 3 is arranged below the folding pinch roller 21 , and includes a fixed tooth plate 31 , a clamping tooth plate 32 , a guide rod cylinder 33 , and an overturning cylinder 34 . The fixed tooth plate 31 and the clamping tooth plate 32 include a tooth plate beam 37 and a tooth bar 38 . Both the fixed tooth plate and the clamping tooth plate can be carved with a flat plate, or a plurality of toothed bars 38 can be fixed and vertically installed on the toothed plate beam 37, and the toothed bars 38 are distributed at intervals, and there are toothed plates between the toothed bars The gap 39 forms a gap for giving way, which is convenient for the bag discharge device 4 to stretch into it and implement bag discharge (such as Figure 9 , Figure 10 shown).

[0041] The cylinder body of the guide rod cylinder 33 is fixedly installed under the middle of the tooth plate crossbeam 37 of the fixed tooth plate 31, and the guide rod cylinder end seat 36 is ...

Embodiment 2

[0051] The difference from the first embodiment mainly lies in the bag discharge device and the bag discharge movement device. (Such as Figure 12 shown). The clamping plate device is directly rotated and installed on the frame 1. The bracket 43 of the bag discharge movement device and the cylinder 44 of the bag discharge movement device are installed at the rear end of the frame. A manipulator device is installed on the support 43. The clamping plate device can only be turned over Displacement, the manipulator device 45 as the bag discharging device can move relative to the clamping plate device with the bracket 43 . The overturning cylinder 34 that is installed on one end of the fixed tooth plate 31 and the other end of the fixed tooth plate are directly installed on both sides of the frame 1, and the clamping plate device can flip and swing back and forth on the frame 1; the support 43 is installed on the The rear end both sides of frame 1, between support 43 and frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com