Packaging method and apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

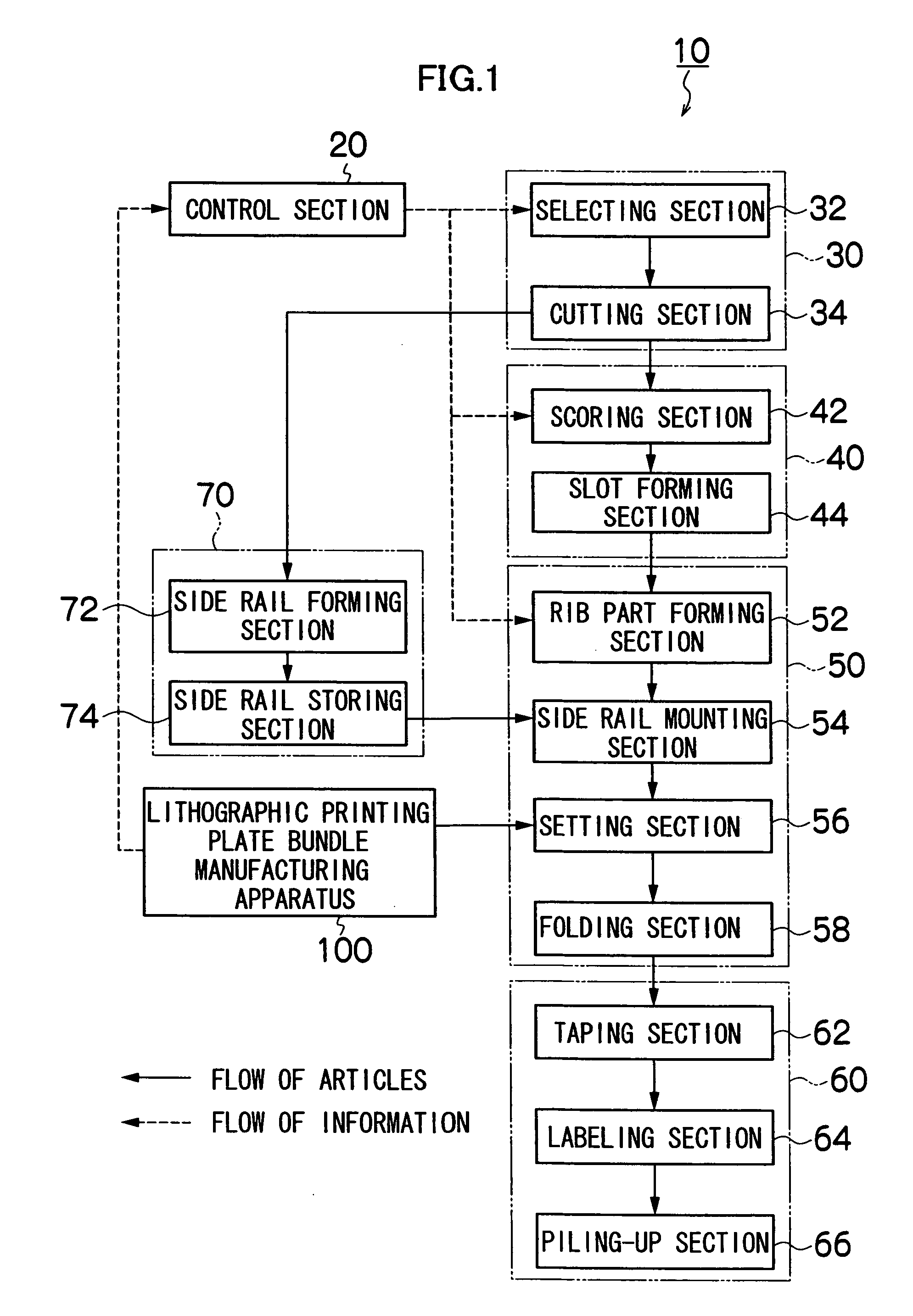

[0032]Preferred embodiments of a packaging method and apparatus in accordance with the present invention will now be described with reference to the accompanying drawings.

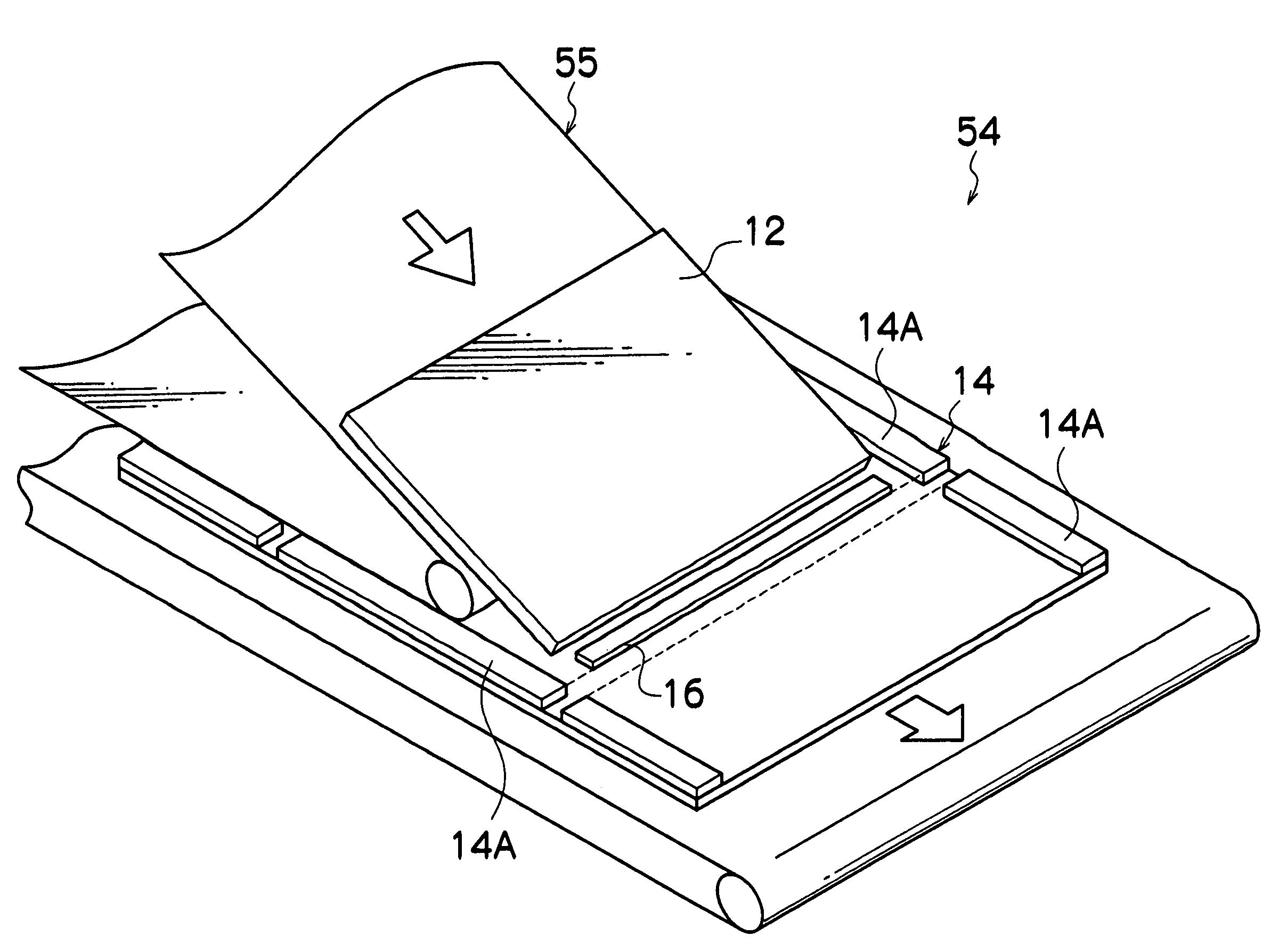

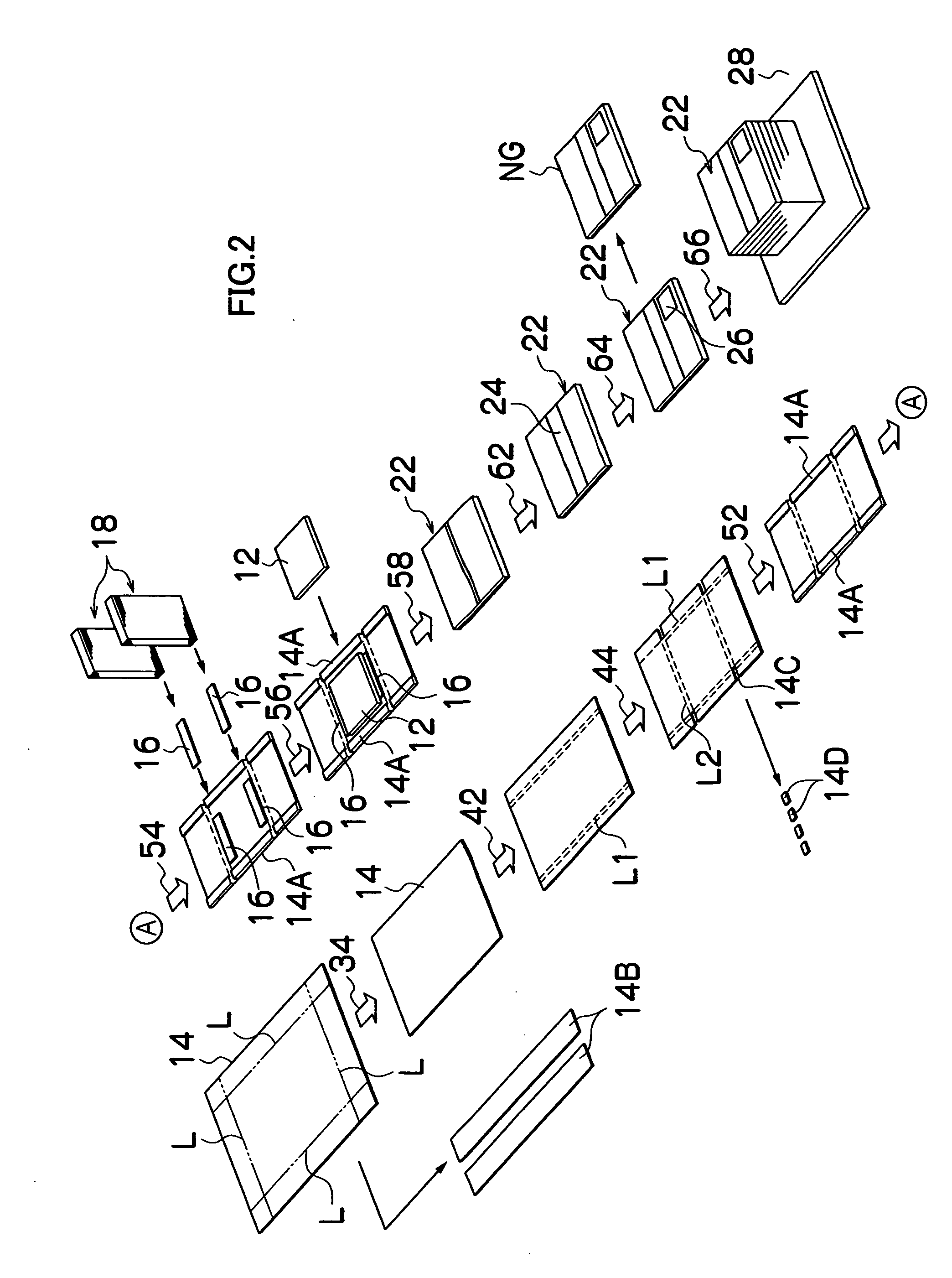

[0033]FIG. 1 is a block diagram showing a general configuration of a packaging apparatus 10 according to an embodiment of the present invention, and FIG. 2 is a perspective view schematically showing the sequence of packaging state. Reference numerals applied to arrow marks in FIG. 2 correspond to reference numerals applied to process sections in FIG. 1, and each of the arrow marks means that the working in the corresponding process section is performed.

[0034]The packaging apparatus 10 is an apparatus that packages a packaged article or a lithographic printing plate bundle 12 by folding a packaging material or a corrugated fiberboard sheet 14 shown in FIG. 2 to form a box-shaped packaging body 22.

[0035]As shown in FIG. 1, the packaging apparatus 10 includes a control section 20, a packaging material supplying secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com