Internal combustion engine cylinder sleeve-piston ring friction performance testing machine with variable reciprocating stroke

A reciprocating motion and piston ring technology, applied in the direction of testing wear resistance, etc., can solve the problem that the stroke cannot be changed, and achieve the effects of easy acquisition, good repeatability of test results, and easy control of test parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

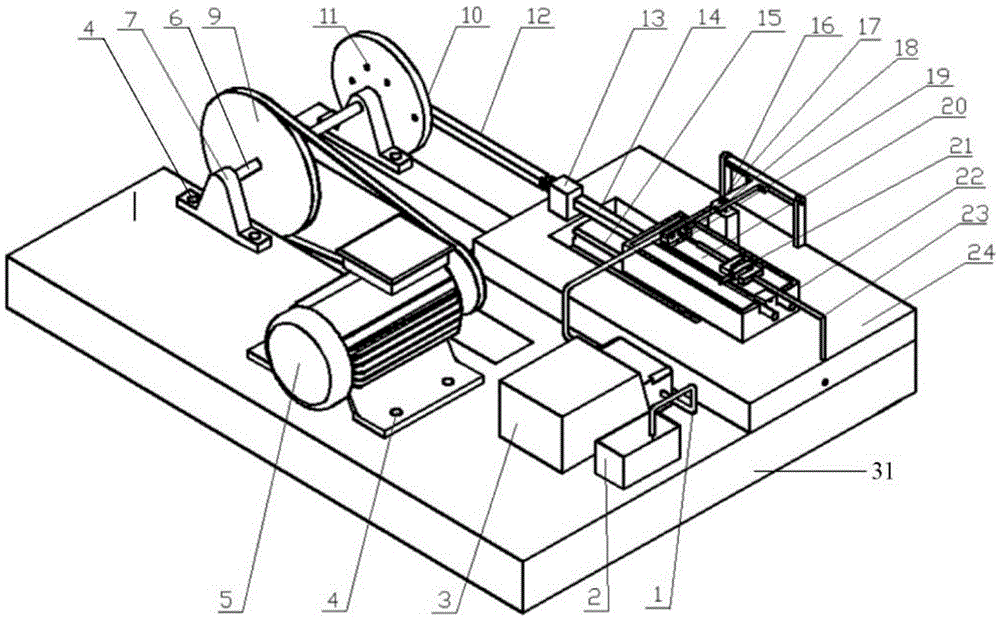

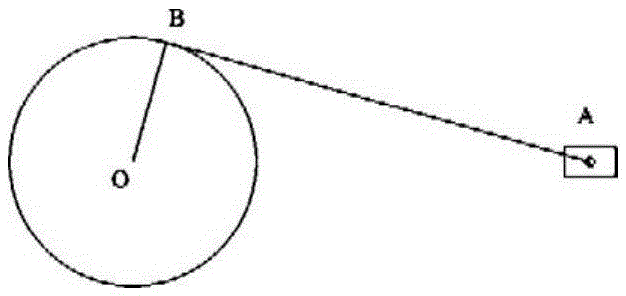

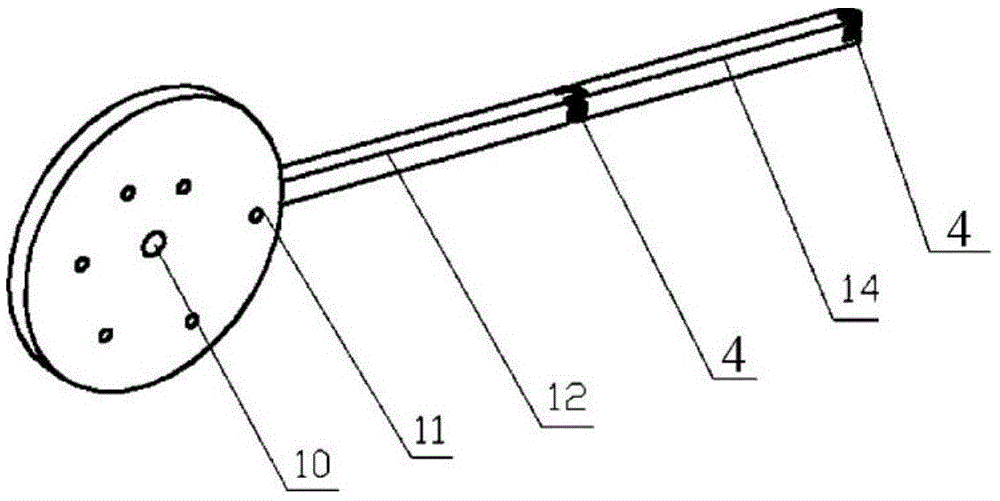

[0038]A cylinder liner-piston ring friction performance testing machine for an internal combustion engine with a variable reciprocating motion stroke, including a lubricating oil pipe 1, an oil tank 2, a peristaltic pump 3, a bolt 4, a motor 5, a pulley shaft 6, a support 7, a large pulley 9, and Variable radius crank disc 10, pin hole 11 for installing cylindrical pin, connecting rod 12, adjusting rod guide seat 13, adjusting rod 14, guide rail 15, loading hole 16 for arranging loading device, cantilever beam 17, piston ring fixture 18, Piston ring test piece 19, cylinder liner test piece 20, tension pressure sensor 21, cylinder liner base 22, sensor bracket 23, platform 24 bottom plate 31 and measuring rod 32, such as Figure 1 ~ Figure 4 As shown, the specific structure is:

[0039] The platform 24 is fixed on the base plate 31, and two bearings 7 are relatively parallel fixed on the base plate 31 with bolts 4, and the two ends of the pulley wheel shaft 6 are respectively r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com