A kind of high-strength and tough single-phase cast magnesium alloy and preparation method thereof

A casting magnesium alloy, single-phase technology, applied in the field of magnesium alloys, can solve the problems of low absolute strength, poor plasticity, and difficult deformation of magnesium alloys, achieve good comprehensive mechanical properties, good plasticity, and improve the sliding resistance of the base surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

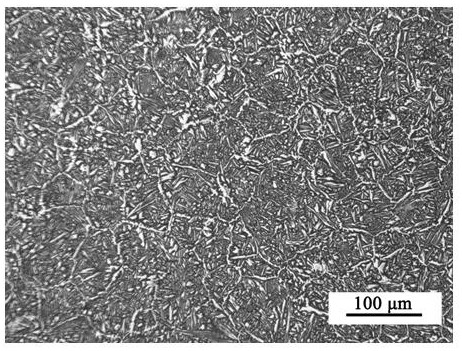

[0030] Dosing according to the composition of Mg-25%Sc-0.6%Zr (mass fraction), after the surface is polished clean, put it into the vacuum induction furnace, start the inverter power supply, gradually increase the power to 10 KW, and then add 5 KW every 2~3 minutes, Until about 40 KW. After the charge in the crucible is melted, it is refined for 2~4 minutes. The alloy is poured after standing in the furnace for 60-90 s. After the ingot is cooled in the mold, it is taken out from the furnace.

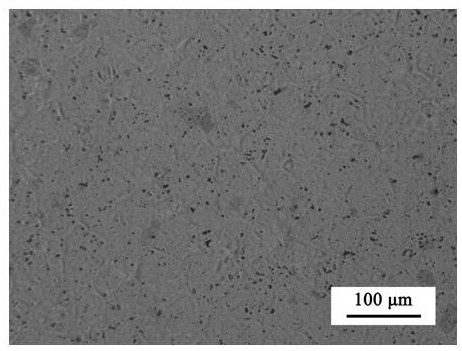

[0031] Embed the prepared magnesium alloy in a stainless steel crucible with graphite, put the crucible in a muffle furnace, raise the temperature from room temperature to 500°C, the heating rate is 1°C / min, and carry out heat preservation after reaching the set temperature of 500°C. Time 5h, turn off the power after the heat preservation is completed, take out the crucible and quench it in water immediately to complete the heat treatment.

[0032] After the heat treatment was complet...

Embodiment 2

[0037] Dosing according to the composition of Mg-20%Sc-0.4%Zr (mass fraction), after the surface is polished clean, put it into the vacuum induction furnace, start the inverter power supply, gradually increase the power to 10 KW, and then add 5 KW every 2~3 minutes, Until about 40 KW. After the charge in the crucible is melted, it is refined for 2~4 minutes. The alloy is poured after standing in the furnace for 60-90 s. After the ingot is cooled in the mold, it is taken out from the furnace.

[0038] Embed the prepared magnesium alloy in a stainless steel crucible with graphite, put the crucible into a muffle furnace, raise the temperature from room temperature to 510°C, and the heating rate is 1°C / min. After reaching the set temperature of 510°C, perform heat preservation treatment. Time 4h, turn off the power after the heat preservation is completed, take out the crucible and quench it in water immediately to complete the heat treatment.

[0039] After the heat treatment,...

Embodiment 3

[0044] Dosing according to the composition of Mg-15%Sc-0.2%Zr (mass fraction), after the surface is polished clean, put it into the vacuum induction furnace, start the inverter power supply, gradually increase the power to 10 KW, and then add 5 KW every 2~3 minutes, Until about 40 KW. After the charge in the crucible is melted, it is refined for 2~4 minutes. The alloy is poured after standing in the furnace for 60-90 s. After the ingot is cooled in the mold, it is taken out from the furnace.

[0045] Embed the prepared magnesium alloy in a stainless steel crucible with graphite, put the crucible into a muffle furnace, raise the temperature from room temperature to 520°C, and the heating rate is 1°C / min. Time 3h, turn off the power after the heat preservation is completed, take out the crucible and quench it in water immediately to complete the heat treatment.

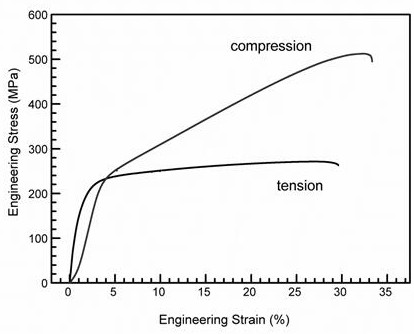

[0046] After the heat treatment, the mechanical properties of the alloy were tested at room temperature, and the mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com