An integrated method for in-situ powder coating and electrode plate preparation for lithium-sulfur batteries

A lithium-sulfur battery, in-situ technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of low production efficiency, long preparation period and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

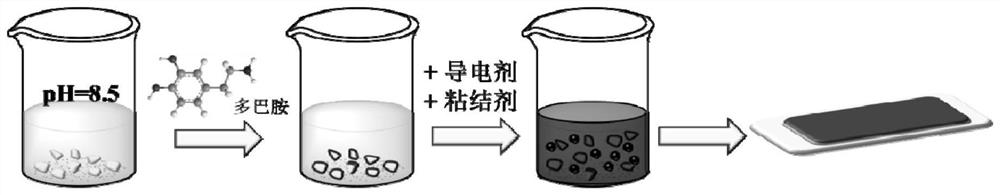

[0041] This example is used in the integrated method of in-situ powder coating and electrode plate preparation for lithium-sulfur batteries (flow chart as shown in figure 1 shown), including the following steps:

[0042] 1) According to the volume ratio of absolute ethanol and deionized water of 1:2, mix absolute ethanol and water; under stirring conditions, add ammonia water drop by drop to the above system, and adjust the pH value of the system to 8.5 (detect with a pH meter) to obtain a mixed solution;

[0043] 2) Take elemental sulfur (positive electrode active material) and add it to the mixed solution obtained in step 1) (so that the concentration of elemental sulfur is 0.1g / ml), and ultrasonically disperse it for 30 minutes; then, the mass ratio of elemental sulfur to dopamine hydrochloride is 98 :2 ratio, add dopamine hydrochloride, continue to stir 2h, get suspension;

[0044] 3) Place the suspension obtained in step 2) in a blast drying oven at 80°C for 30 minutes ...

Embodiment 2

[0051] This embodiment is used for the integrated method of in-situ powder coating and electrode plate preparation for lithium-sulfur batteries, including the following steps:

[0052] 1) According to the volume ratio of absolute ethanol and deionized water of 1:2, mix absolute ethanol and water; under stirring conditions, add ammonia water drop by drop to the above system, and adjust the pH value of the system to 8.5 (detect with a pH meter) to obtain a mixed solution;

[0053] 2) Take elemental sulfur (positive electrode active material) and add it to the mixed solution obtained in step 1) (so that the concentration of elemental sulfur is 0.1g / ml), and ultrasonically disperse it for 30 minutes; then, the mass ratio of elemental sulfur to dopamine hydrochloride is 96 : The ratio of 4, add dopamine hydrochloride, continue to stir 2h, get suspension;

[0054] 3) Place the suspension obtained in step 2) in a blast drying oven at 80°C for 30 minutes to make the ammonia gas fully...

Embodiment 3

[0060] This embodiment is used for the integrated method of in-situ powder coating and electrode plate preparation for lithium-sulfur batteries, including the following steps:

[0061] 1) According to the volume ratio of absolute ethanol and deionized water of 1:2, mix absolute ethanol and water; under stirring conditions, add ammonia water drop by drop to the above system, and adjust the pH value of the system to 8.5 (detect with a pH meter) to obtain a mixed solution;

[0062] 2) Take elemental sulfur (positive electrode active material) and add it to the mixed solution obtained in step 1) (so that the concentration of elemental sulfur is 0.1g / ml), and ultrasonically disperse it for 30 minutes; then, the mass ratio of elemental sulfur to dopamine hydrochloride is 94 :6 ratio, add dopamine hydrochloride, continue to stir 2h, get suspension;

[0063] 3) Place the suspension obtained in step 2) in a blast drying oven at 80°C for 30 minutes to make the ammonia gas fully volatil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com