Arc striking device for ion plating and ion plating device

A technology of ion coating and arc striking device, which is applied in ion implantation coating, sputtering coating, vacuum evaporation coating and other directions, can solve the problems of small magnetic force of coil passing electromagnetic field, sticking hook, easy gas leakage at sealing parts, etc. Save material and strengthen the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

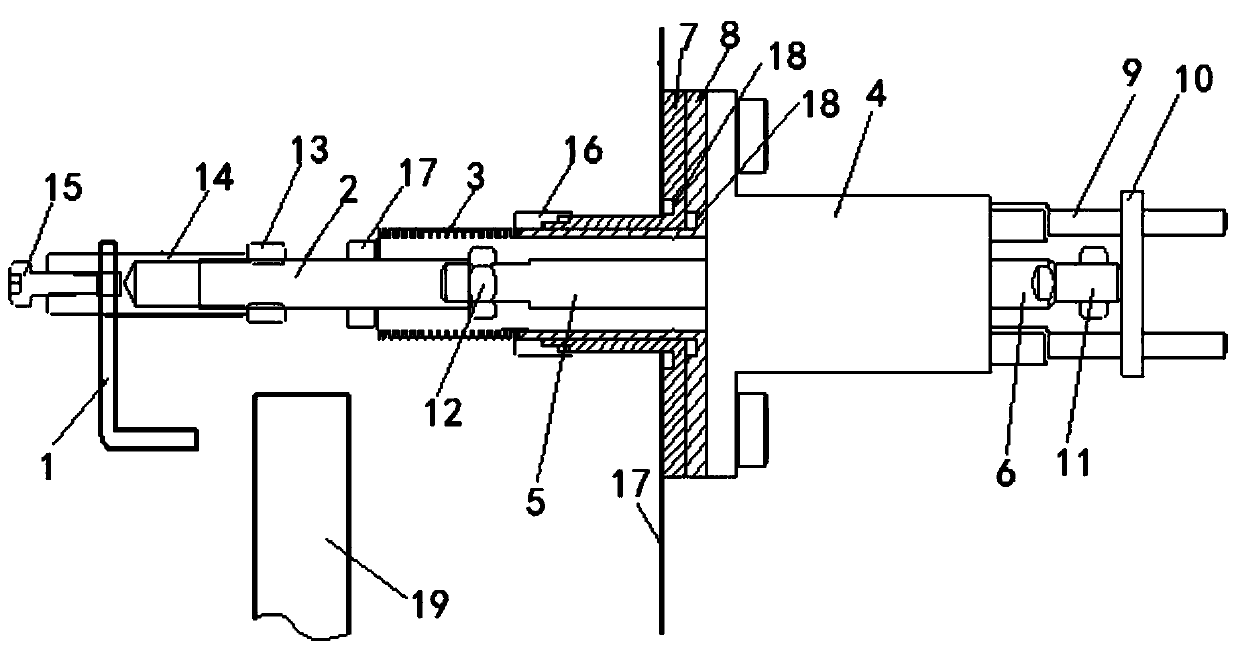

[0032] The invention provides an arc starting device for ion plating and an ion plating device, such as figure 1 As shown, the arc striking device for ion plating in this embodiment includes an arc striking hook 1, a connecting rod 2, a bellows 3, a driving device and a sealing insulator, and a mounting hole is provided on the side wall 20 of the vacuum chamber of the ion plating device , the sealing insulator is used to set and fix in the installation hole and form a sealed connection with the installation hole, the output shaft of the driving device passes through the sealing insulator and is fixedly connected with one end of the connecting rod 2, and the driving device can drive the connecting rod 2 in the axial direction For reciprocating movement, one end of the bellows 3 is fixedly connected with one end of the sealing insulator, the other end of the bellows 3 is fixedly sleeved outside the connecting rod 2 and forms a sealed connection with the connecting rod 2, and the ...

Embodiment 2

[0042] This embodiment provides an ion coating device. The ion coating device in this embodiment includes the arc starting device for ion coating and the vacuum chamber in Embodiment 1. Specifically, the arc starting device for ion coating is fixed in the vacuum chamber. on the side wall 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com