Steel bar bending machine

The technology of bending machine and bending mechanism is applied in the field of steel bending machine, which can solve the problems of reduced service life, redundant requirements, troublesome operation, etc., and achieve the effect of convenient use and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

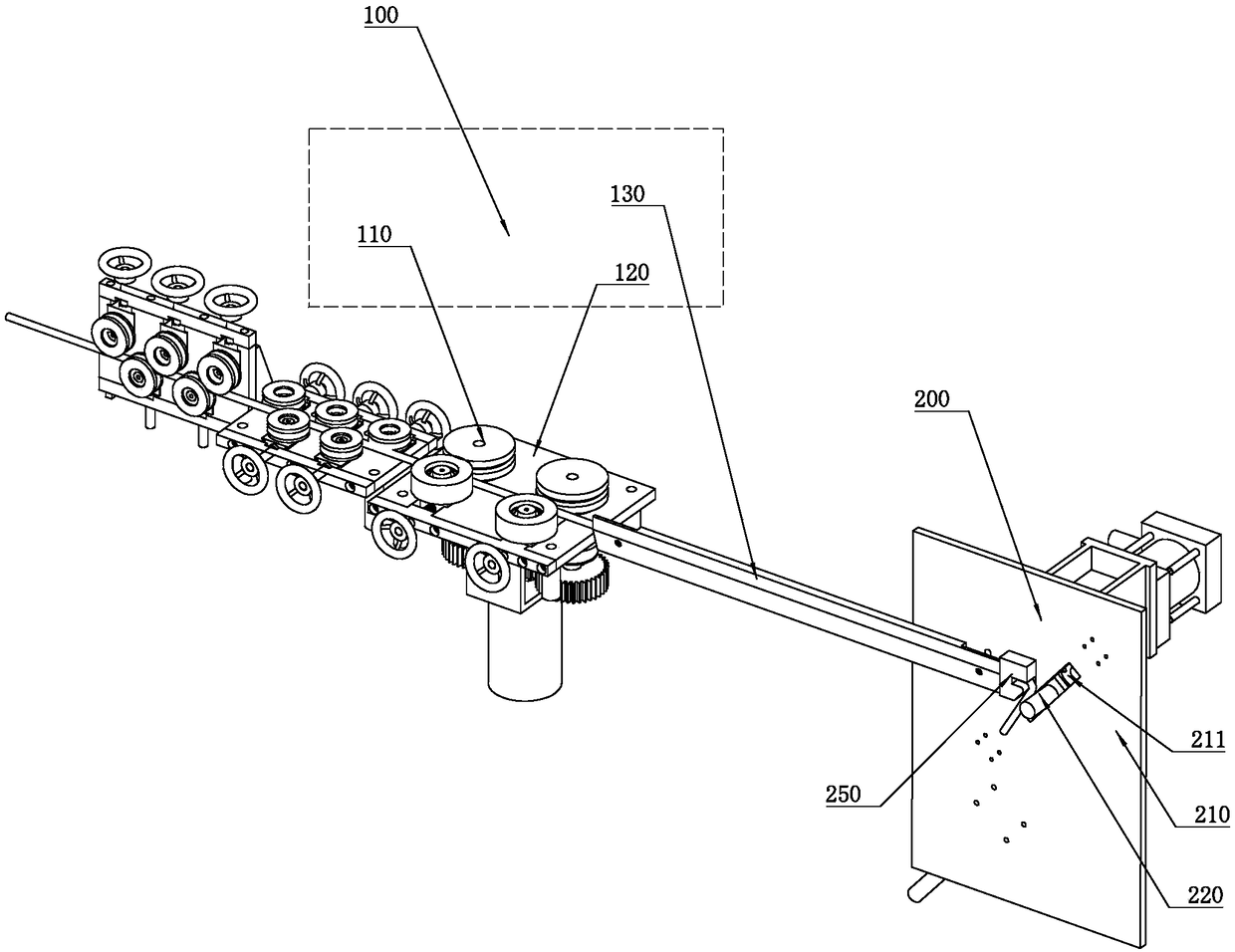

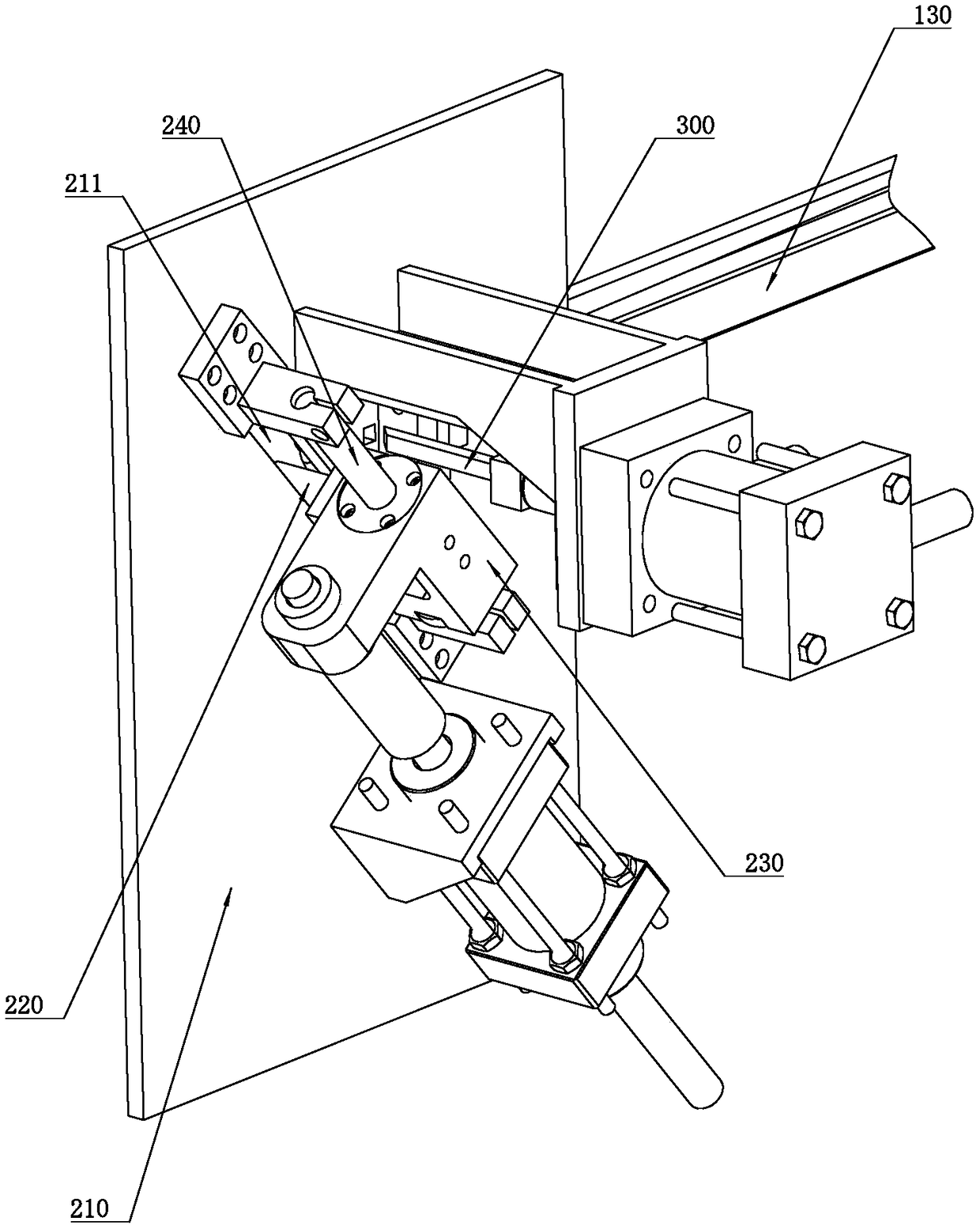

[0018] refer to Figure 1 to Figure 2 , a steel bar bending machine of the present invention includes a conveying device 100 and a bending mechanism 200, the bending mechanism 200 is arranged at the discharge end of the conveying device 100, and the bending mechanism 200 includes a backing plate 210, a fixed block 250, bending knife 220 and oil cylinder; the backing plate 210 abuts against the side of the reinforcing bar, the fixing block 250 is fixed on the backing plate 210, and the fixing block 250 is provided with a through hole for inserting the reinforcing bar, through The upper surface and / or the lower surface of the discharge end of the hole is arranged in an arc shape, and the bending knife 220 is inserted in the backing plate 210 and abuts against the surface of the steel bar, and the bending knife 220 can slide in the steel bar and drive the steel bar to cooperate. The arc-shaped discharge end of the hole is bent, and the bending knife 220 is driven to slide by an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com