Travel limiting device

A limit device and travel limit technology, applied in the field of limit devices, can solve problems such as motor and other components overload damage, reliability deterioration, micro switch damage, etc., achieve reliable limit buffer function, and improve work reliability , The effect of complete system functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

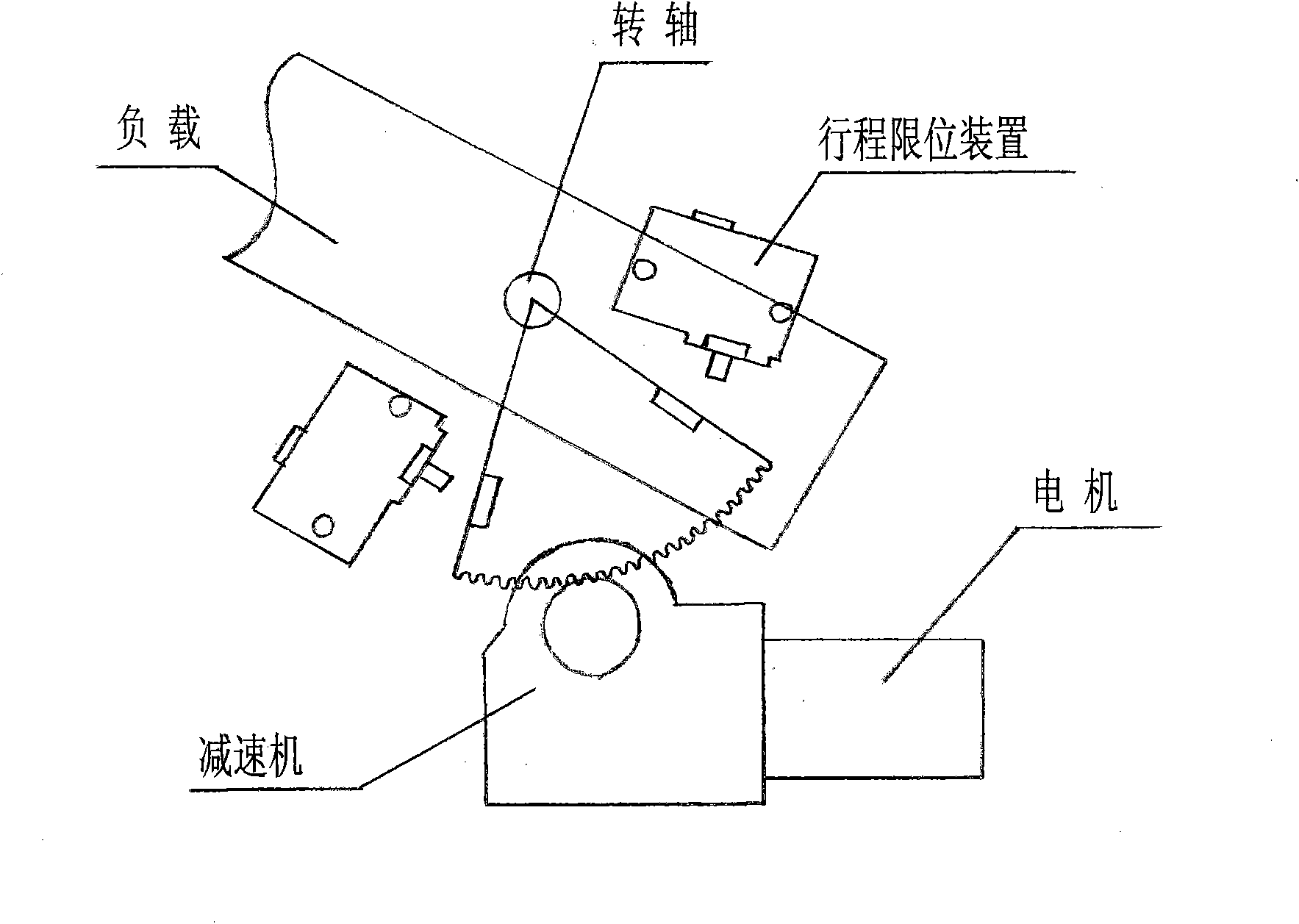

[0035] The overall structural diagram of the stroke limiting device of this embodiment when it cooperates with other components is shown in Figure 1. The stroke limiting device, the rotating shaft, the motor and the reducer are all installed on the platform, and the load is fixed on the platform through the rotating shaft. For the up and down pitching movement, the motor drives the reducer to rotate and meshes with the gears on the load through the gears on the reducer. When the load rotates to a predetermined angle under the action of the motor and the reducer, it meets the spring travel shaft of the new travel limit device. When it continues to move, the spring travel shaft is compressed by external force, and under the action of its internal mechanism, it first triggers The contact of the micro switch gives an electrical signal indicating that the load is in place, and drives the motor controller to cut off the power supply of the motor. The load continues to rotate forward...

Embodiment 2

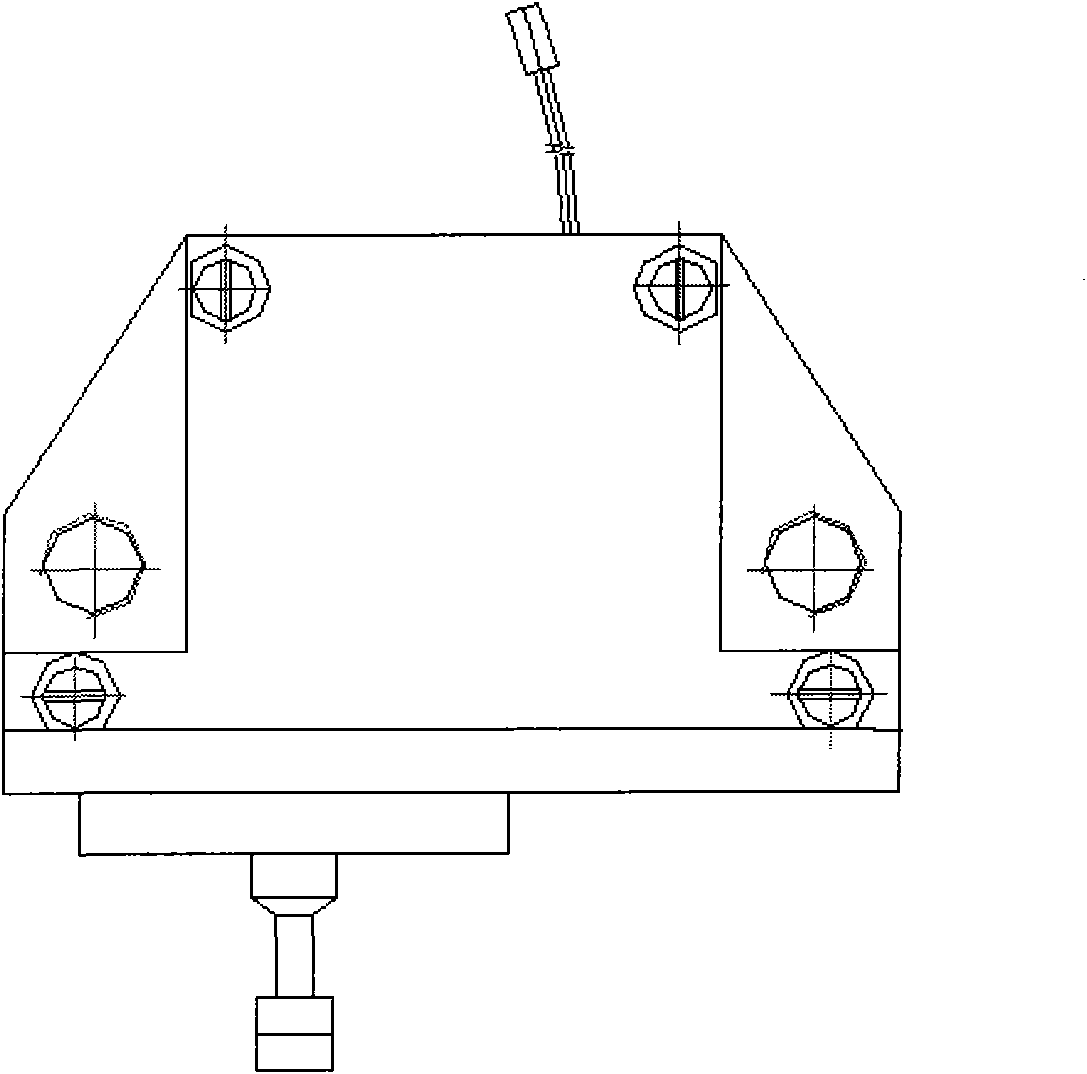

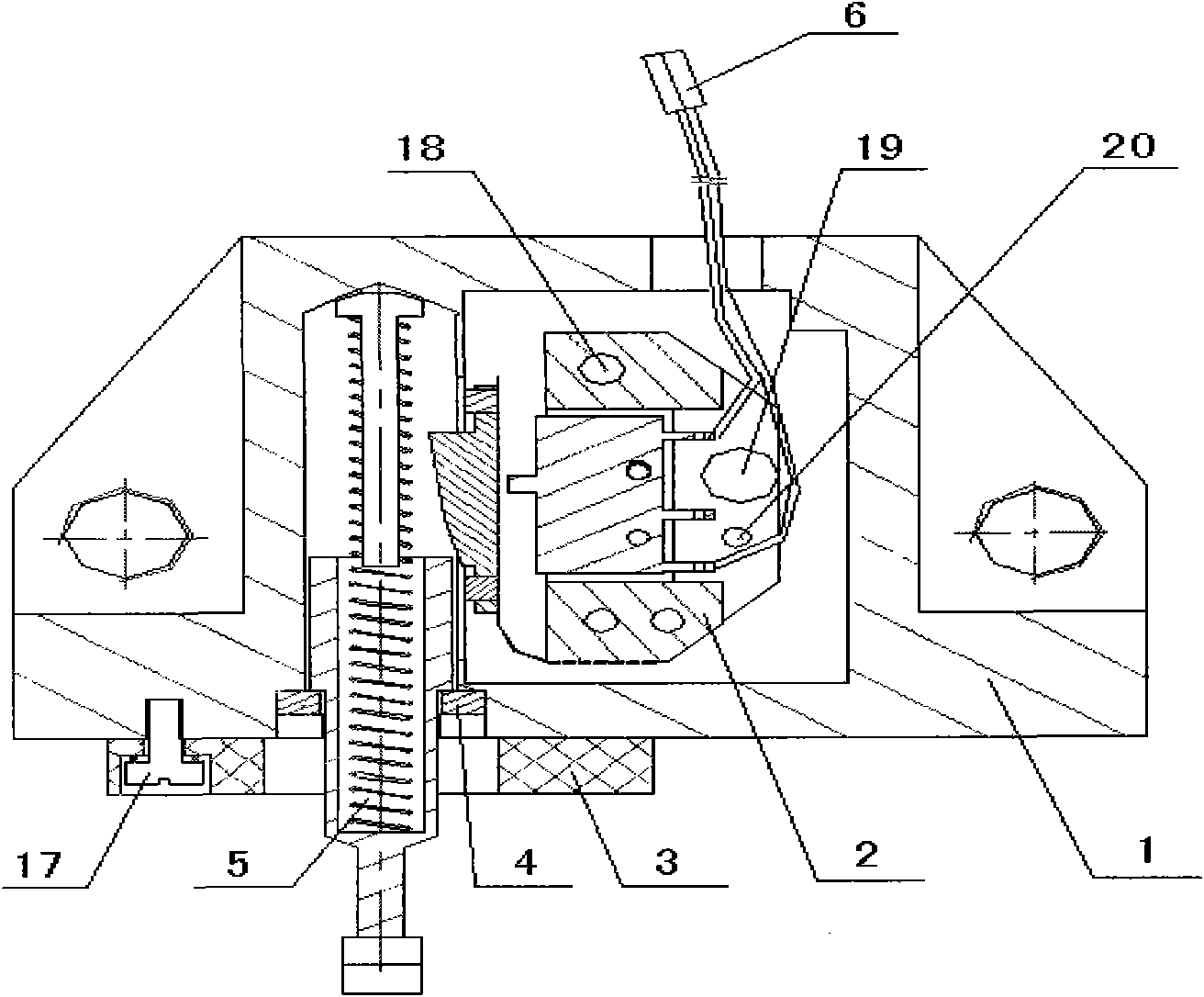

[0037] The specific structure of the stroke limiting device of this embodiment is as follows: Figure 2-6 Shown: mechanical limit implementation: the limit switch box 1 is the carrier for component installation, the rubber pad 3 is installed on the side of the limit switch box through screws 17, and the rubber material is hard rubber.

[0038]Electric limit implementation mode: the spring stroke shaft 5 and the stroke control switch 2 are the two main assemblies for implementing electric limit. The spring stroke shaft 5 is fixed through the faceplate nut 4 and the long cylindrical hole on the side of the limit switch box 1. The hollow shaft 15 can freely expand and contract in the cylindrical hole. Compatible with the internal thread on it. The central shaft 13 is placed inside the spring 14 , and the spring 14 is placed inside the hollow shaft 15 . When the central shaft 13 is compressed, it can freely slide along the inner cavity of the limit switch box 1; after the force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com