Multipoint automatic oil filler of railway turnout

A technology of automatic oil injection and turnout, which is applied in the direction of railway car body parts, railway auxiliary equipment, track lubrication, etc., can solve the problems of high labor intensity, locking hook cannot be locked, and inaccurate positioning of switch rails, etc., to achieve small size, Simple structure, high oil pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

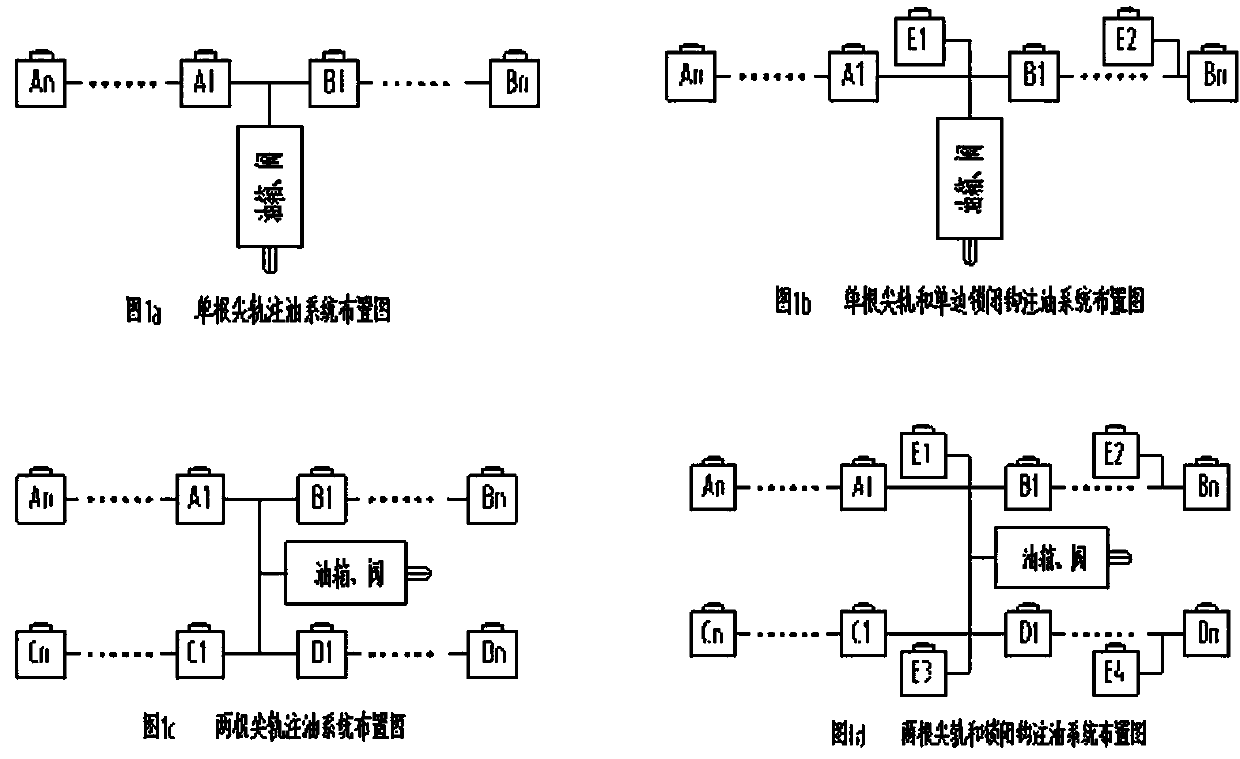

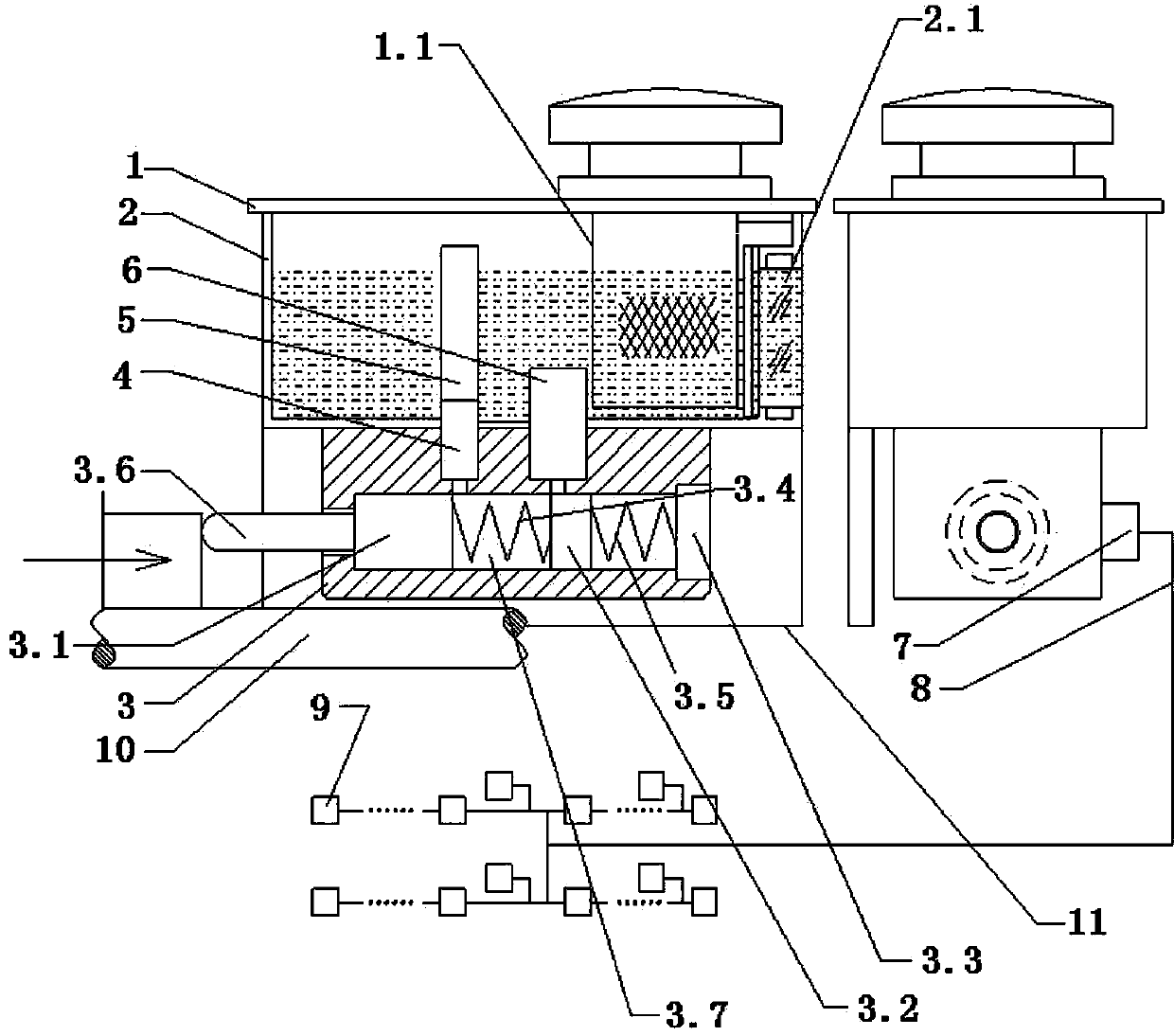

[0018] see Figure 1~3 The present invention will be further described below in conjunction with embodiment.

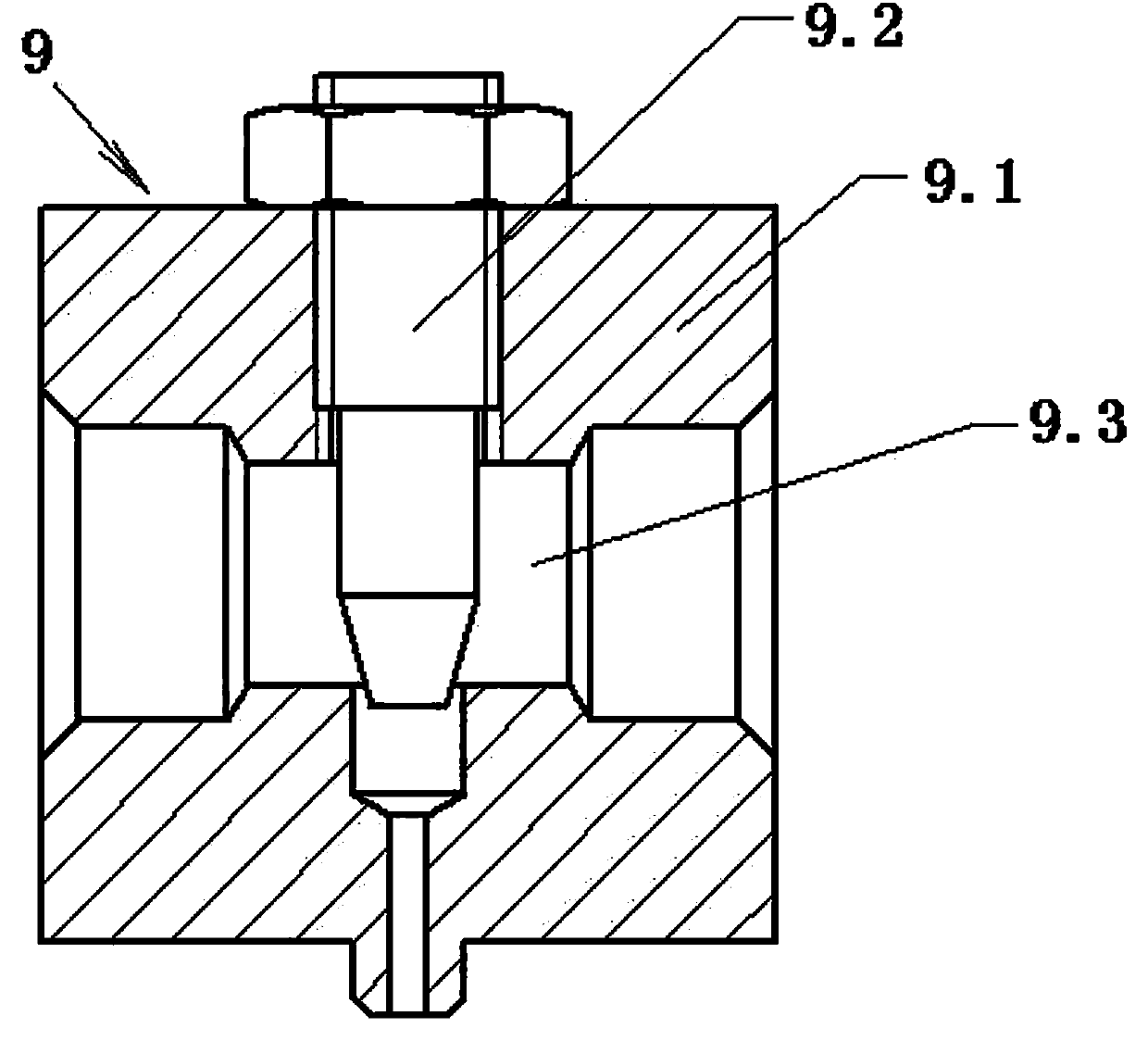

[0019] A railway maintenance device, particularly a multi-point automatic oiler for railway turnouts, comprising a fuel tank 2, a fuel tank cover 1 and a support 11 supporting the fuel tank, characterized in that: the bottom of the fuel tank 2 is provided with a valve body 3, the valve There is a cavity in the body 3, the two ends of the cavity are respectively arranged with a valve core 3.1 and a plug 3.3, and a slide valve 3.2 is arranged between the valve core 3.1 and the plug 3.3, the valve core 3.1, the slide valve 3.2 and the plug 3.3 are respectively connected by the first and second elastic parts 3.4 and 3.5, and there is a push rod 3.6, one end of which is connected to the valve core 3.1 and the other end extends to the outside of the valve body 3, and the cavity passes through the oil inlet pipe 4, The exhaust pipe 5 and the oil-gas valve 6 communicate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com