Double-let-off type composite shed water jet loom

A water-jet loom and double let-off technology, applied to other shedding mechanisms, looms, textiles, etc., can solve the problems of increasing the beating stroke, high warp density, reducing the amount of shedding, etc., to reduce breakage The effects of frequency, soft touch, and reduced opening volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

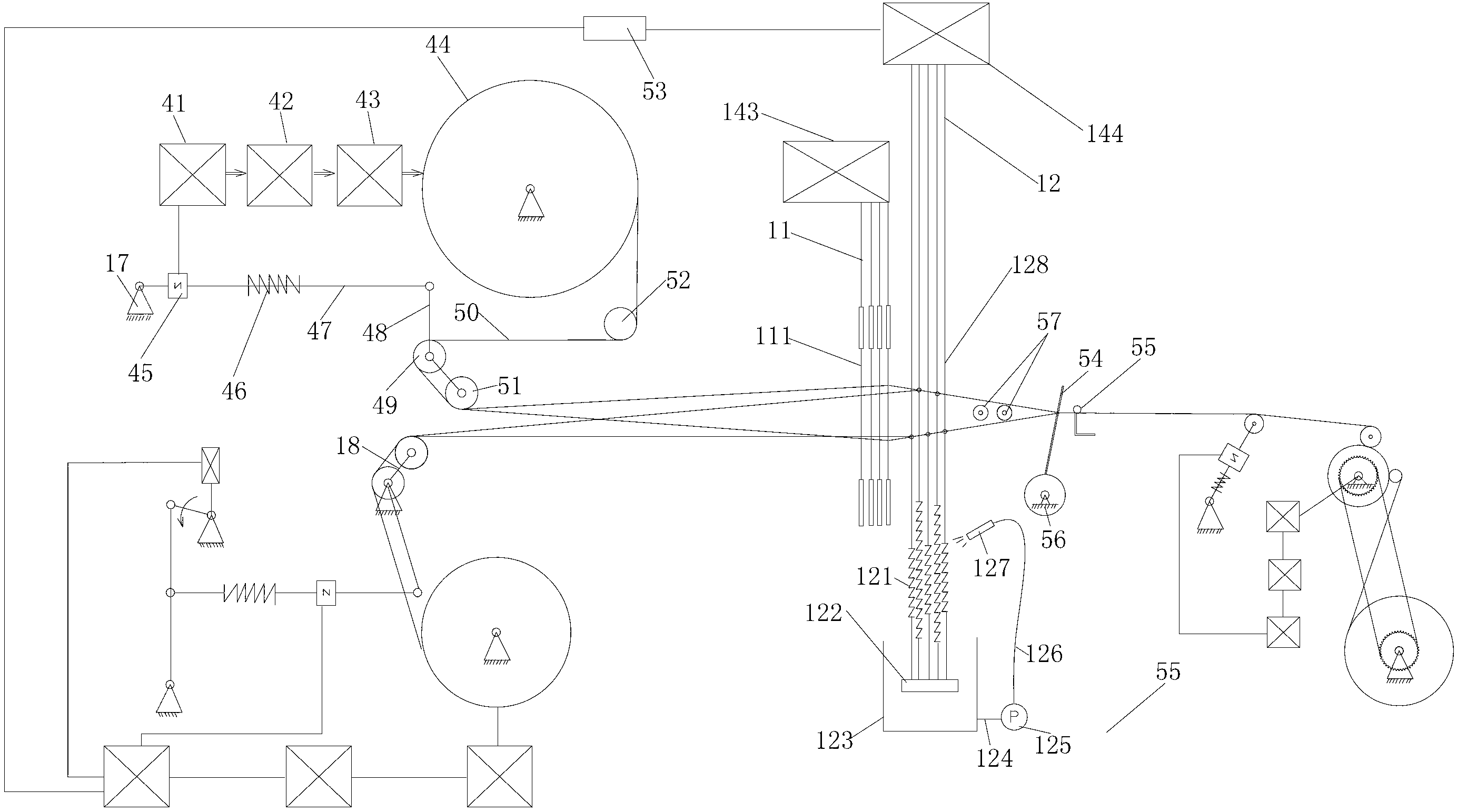

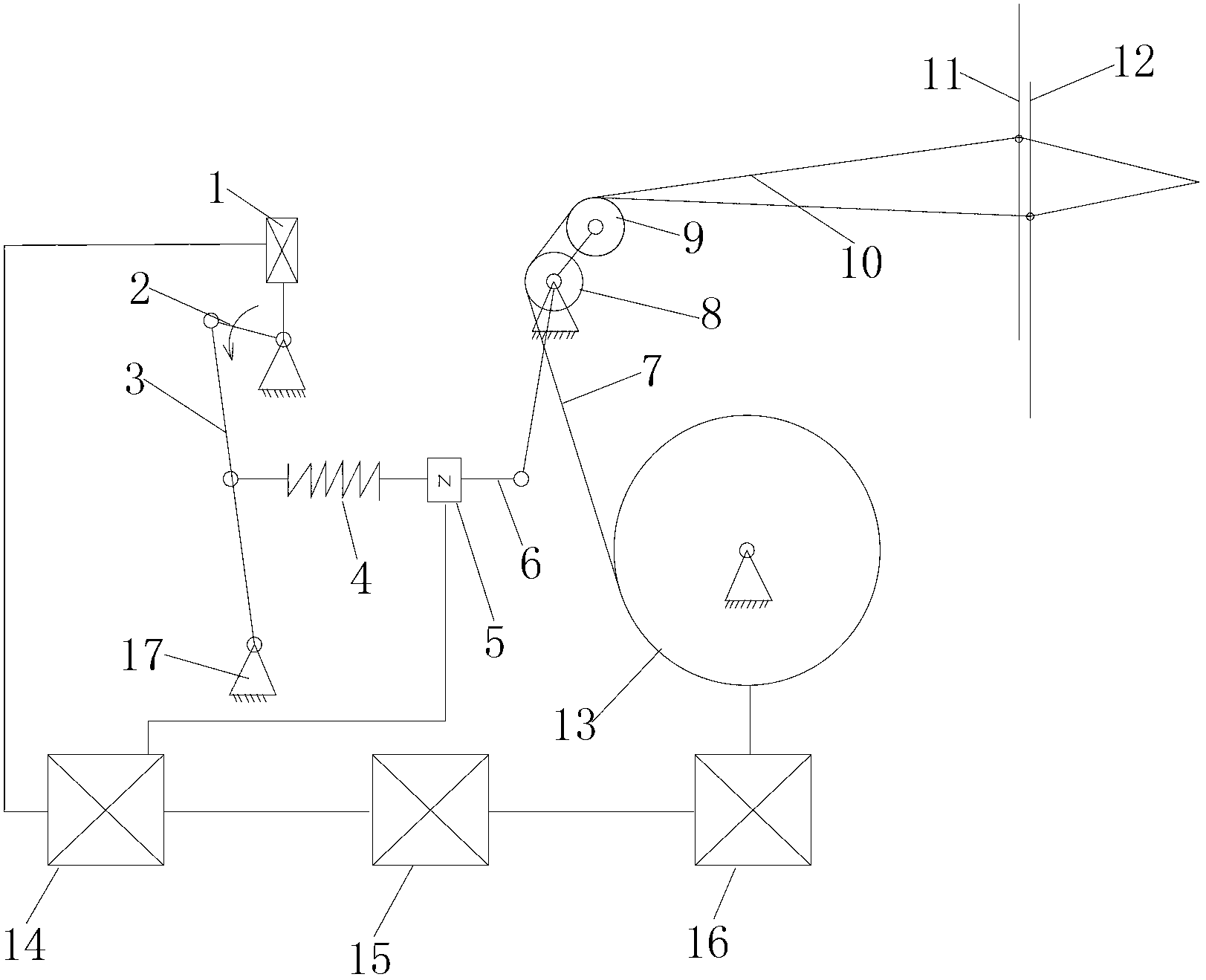

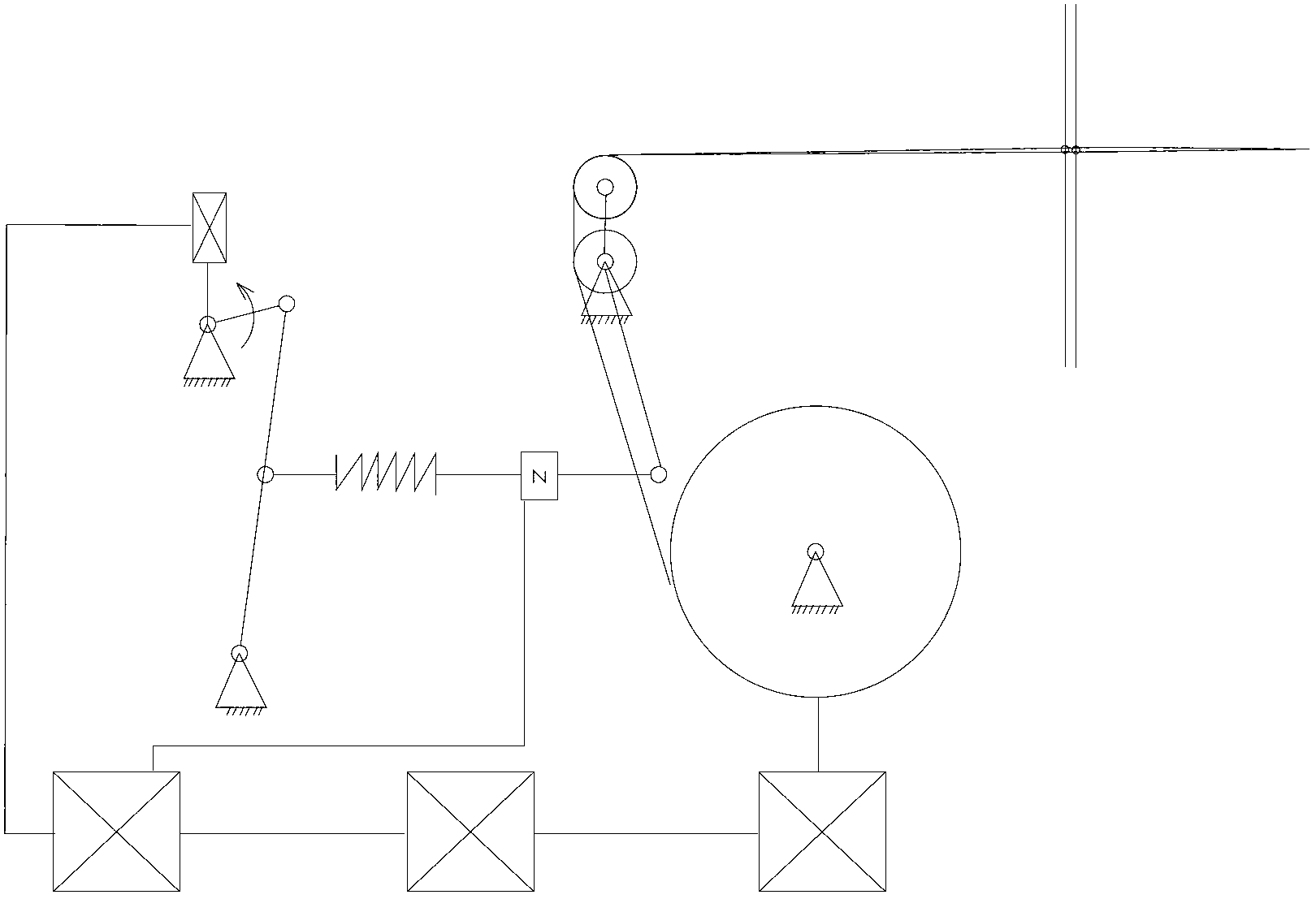

[0021] refer to figure 1, the double let-off type composite shedding water jet loom of the present invention comprises positive type electronic let-off device, negative type electronic let-off device, main shaft encoder 53, dobby 11, jacquard machine 12, steel reed 54, stable loom Device 55, beating-up shaft 56, nozzle 57 and positive take-up device, the passive electronic warp let-off device is arranged above the positive electronic warp let-off device, and the positive electronic warp let-off device is connected with the main shaft encoder 53 , the main shaft encoder 53 is connected with the jacquard machine 12, and the dobby machine 11 and the jacquard machine 12 are arranged on the right side of the positive electronic warp let-off device and the negative electronic warp let-off device, and the jacquard machine 12 is arranged on the right side of the dobby machine 11 , the positive take-up device is arranged on the right side of the jacquard machine 12, between the positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com