Woven loop press base fabric having high density top layer

a top layer, high density technology, applied in weaving, drying machines, light and heating equipment, etc., can solve the problems of undesirable vibration, small irregularities or imperfections in the support layer, and fabrics typically provide limited batt anchorage and sheet suppor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

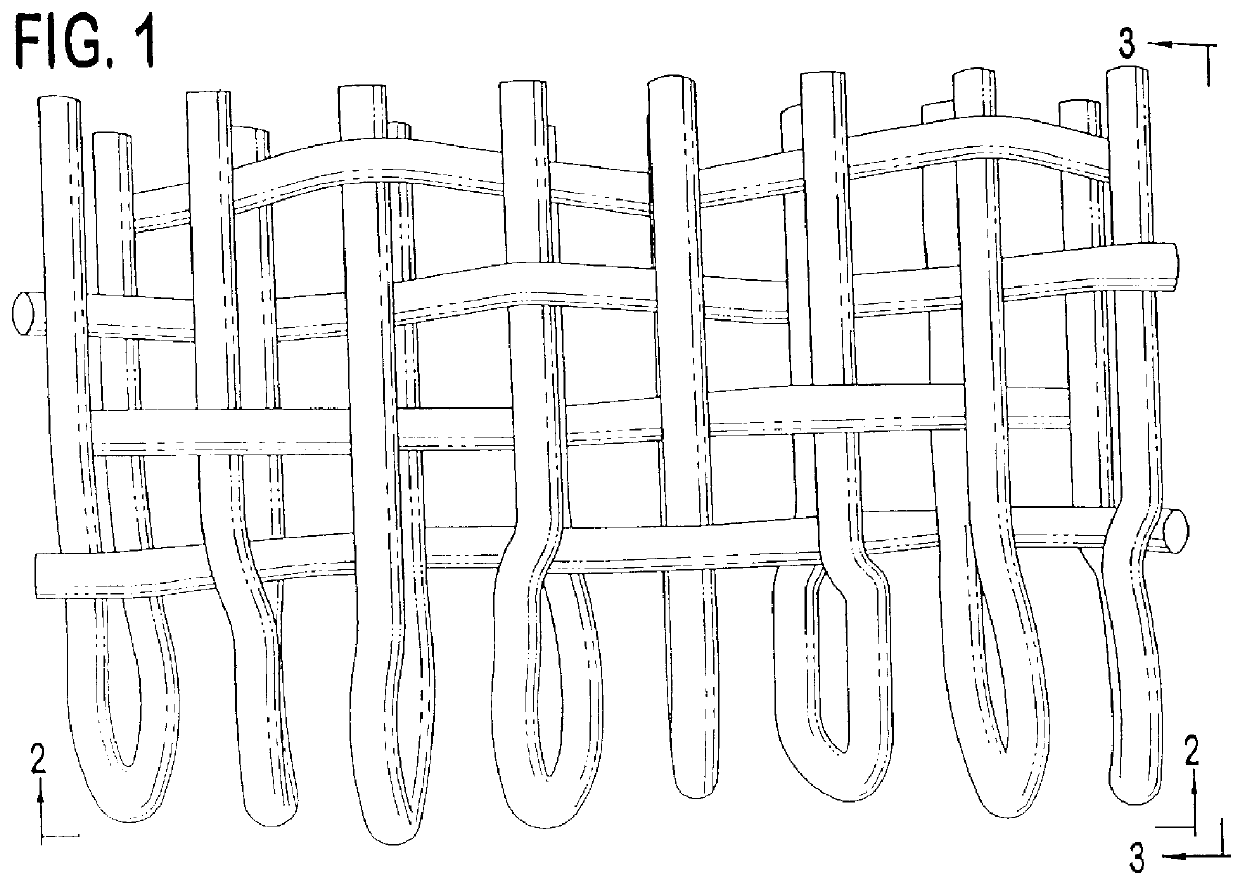

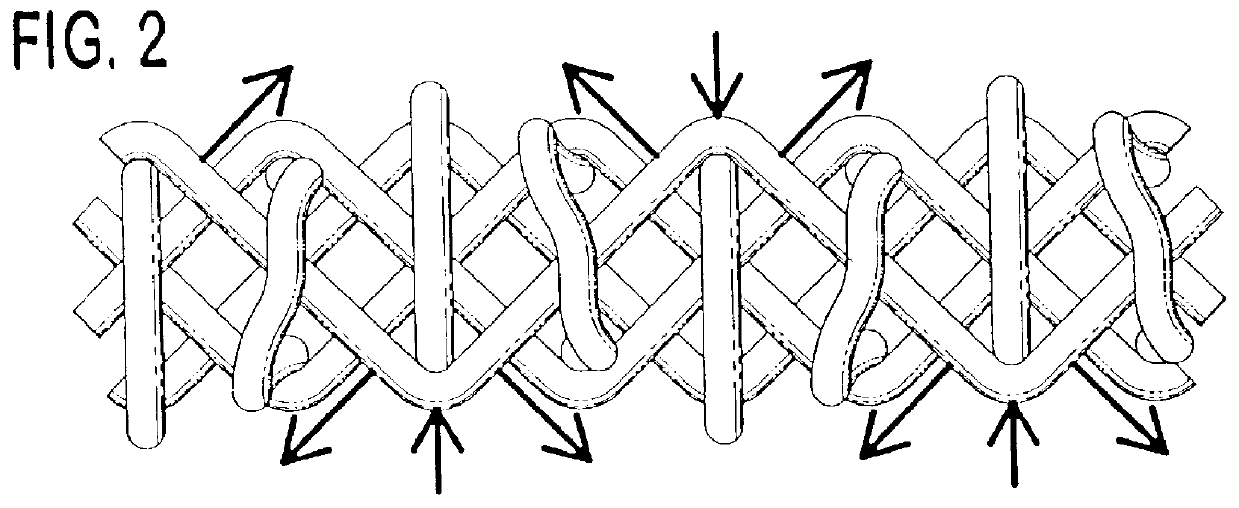

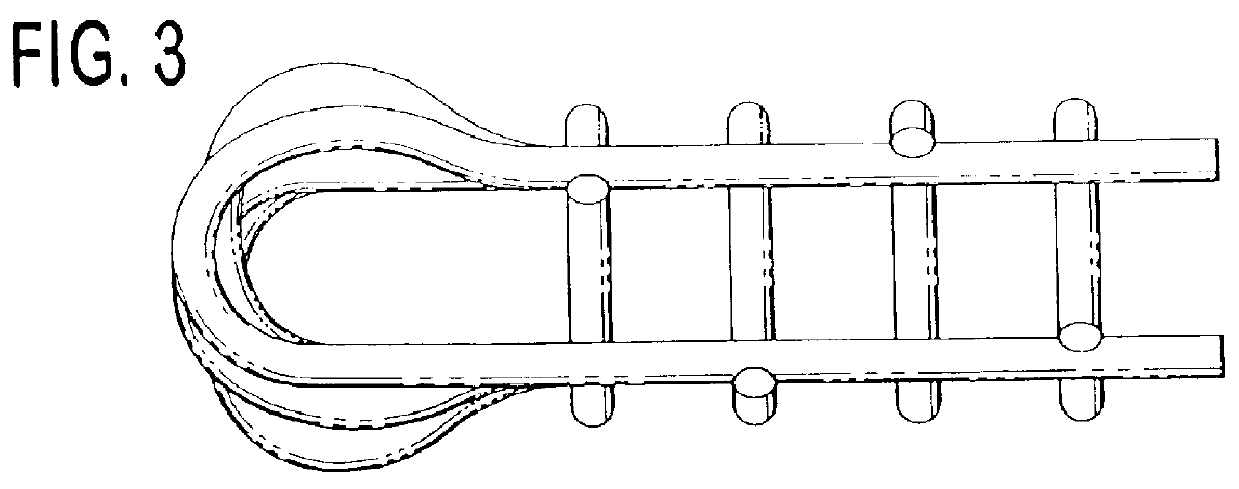

The preferred embodiment will be described with reference to the drawing figures wherein like numerals represent like elements throughout.

Referring to FIGS. 4 and 5 the preferred fabric 100 generally comprises a base fabric 110 with batt material 112 attached thereto. The base fabric 110 comprises three layers of machine direction (MD) yarns 114, 116 and 118 interwoven with a system of cross-machine direction (CMD) yarns 120. MD layers 114 and 116 are woven in stacked pairs and form seam loops 122 at each end of the base fabric 110. The third layer MD yarns 118 extend above MD layers 114 and 116 and are substantially parallel thereto. In the preferred embodiment, two third layer MD yarns 118 are provided for every pair of stacked MD yarns 114 and 116.

The fabric 110 is preferably endless woven using a two shuttle loom. The first shuttle weaves the lower and intermediate MD layers 114 and 116 and the second shuttle weaves the upper MD layer 118. As shown in FIG. 6, the base fabric 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com