Industrial automation fried flour cake production line

An industrial automation and production line technology, applied in baking, dough extruder, baked food, etc., can solve problems such as the inability to form large-scale production, restrict the inheritance and development of traditional classic snacks, and the inability to realize industrialized production of Chinese specialty snacks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

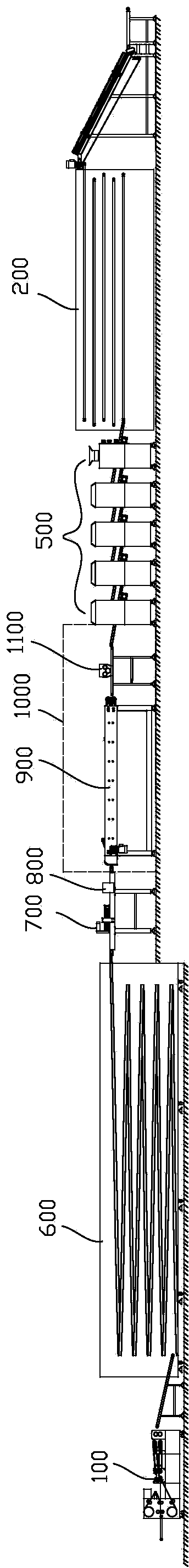

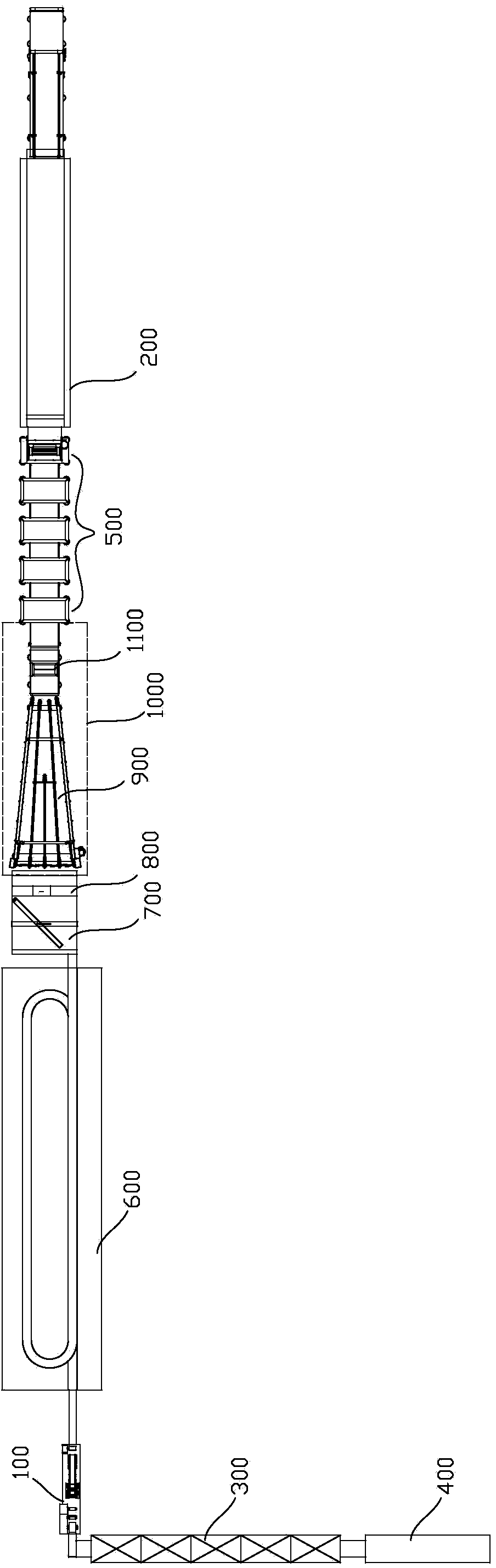

[0063] As a preferred embodiment of the present invention, please refer to figure 1 , 2 And 4, an industrial automatic production line of pastry biscuits, comprising a moving soft noodle constant temperature noodle conveying system 200, a dough forming system 500, a dough oiling system 1100, an oiled dough thinning system 900, and an oiled dough condiment arranged in sequence Adding system 800, roll filling system 700, moving cylindrical noodle roll constant temperature noodle conveying system 600, traction flattening-coating system 100, metering and cutting system, tunnel quick-freezing system 300 and packaging system 400.

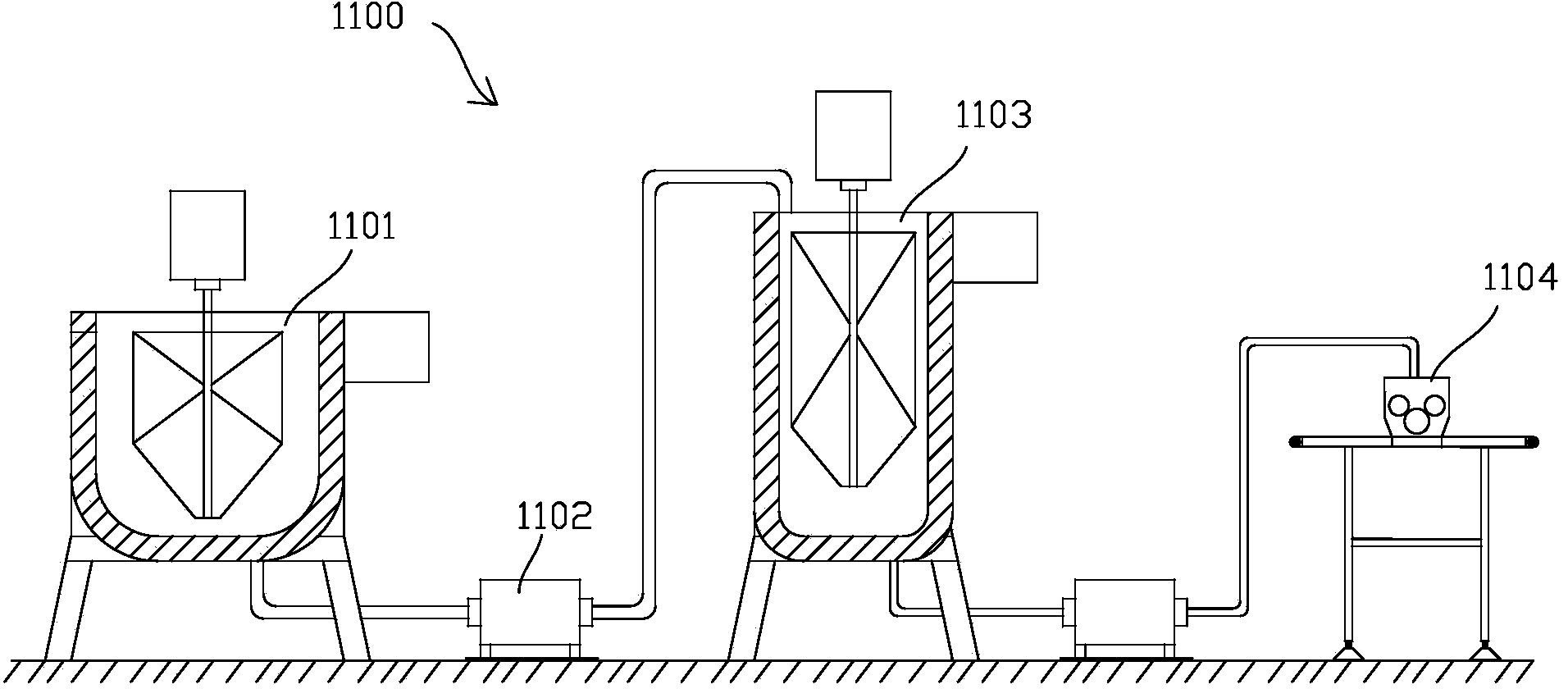

[0064] Please also refer to image 3 , the skin oiling system 1100 includes a grease viscosity control device 1101, a grease mixing device 1103, a grease spraying device 1104 and two delivery pumps 1102 connected between the three.

[0065] see figure 1 and 2 , the dough oiling system 1100 and the oiled dough thinning system 900 are placed in the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com