Preparation method of electrode slice

A technology of electrode sheet and electrode slurry, which is applied in the field of electrode sheet preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

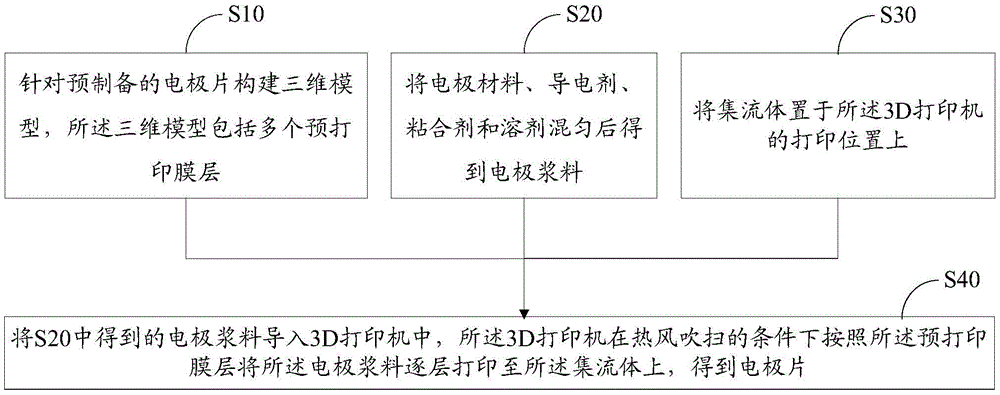

[0018] The preparation method of the electrode sheet will be further described in detail mainly in conjunction with the accompanying drawings.

[0019] Such as figure 1 Shown, the preparation method of the electrode sheet of an embodiment, comprises the following steps:

[0020] S10. Construct a three-dimensional model for the pre-prepared electrode sheet, where the three-dimensional model includes a plurality of pre-printed film layers.

[0021] Generally, computer drawing software, such as Pro / Engineer, UG (UnigraphicsNX) and other drawing software can be used to construct a three-dimensional model of the pre-prepared electrode sheet. Electrode sheets of various shapes or patterns can be designed according to actual needs, and divided into multiple pre-printed film layers in the designed model to guide the 3D printer to print.

[0022] Generally, the total thickness of the pre-prepared electrode sheet is 50 μm-500 μm, the width range of the electrode sheet is 0.5 mm-600 mm...

Embodiment 1

[0057] Construct a three-dimensional model of the pre-prepared electrode sheet through the professional computer software Pro / Engineer, and reserve a blank area. For the corroded aluminum foil with a width of 600mm and a thickness of 22μm, 18 sets of electrode sheet models with a width of 30mm and a length of 675mm are designed on the front side, and 18 sets of electrode sheet models with a width of 30mm and a length of 655mm are designed on the reverse side. The front and back sides are aligned according to the length direction, and the electrode sheet The total thickness of the film is 222 μm, and it is processed in layers and sliced. Each pre-printed film layer is designed to be 50 μm and imported into a 3D printer. Prepare the electrode slurry, mix the electrode material, conductive agent and binder according to the mass ratio of 80:10:10, wherein the electrode material is activated carbon, the conductive agent is Ketjen Black, and the binder is the mass ratio It is 50:50 ...

Embodiment 2

[0059] The three-dimensional model of the pre-fabricated electrode sheet is constructed by the professional computer software Pro / Engineer. For the corroded aluminum foil with a width of 0.5mm and a thickness of 22μm, an electrode sheet model with a width of 0.5mm and a length of 1000mm is designed on the front side, and an electrode sheet model with a width of 0.5mm and a length of 955mm is designed on the reverse side. The front and back sides are aligned in the length direction, and the total thickness of the pole piece is 262 μm, and it is sliced in layers, and each pre-printed film layer is designed to be 120 μm, and imported into a 3D printer. Prepare the electrode slurry, mix the electrode material, conductive agent and binder according to the mass ratio of 85:7.5:7.5, wherein the electrode material is activated carbon, the conductive agent is Ketjen Black, and the binder is the mass ratio It is 40:60 styrene-butadiene rubber and carboxymethyl cellulose. Add deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com