Regional mobile light source scanning system for laser rapid prototyping technology

A laser rapid prototyping and scanning system technology, applied in laser welding equipment, improving energy efficiency, improving process efficiency, etc., can solve problems such as increasing the volume and load of optical circuit boards, increasing the difficulty of designing rapid prototyping equipment, and expensive prices , to achieve the effect of reducing equipment cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

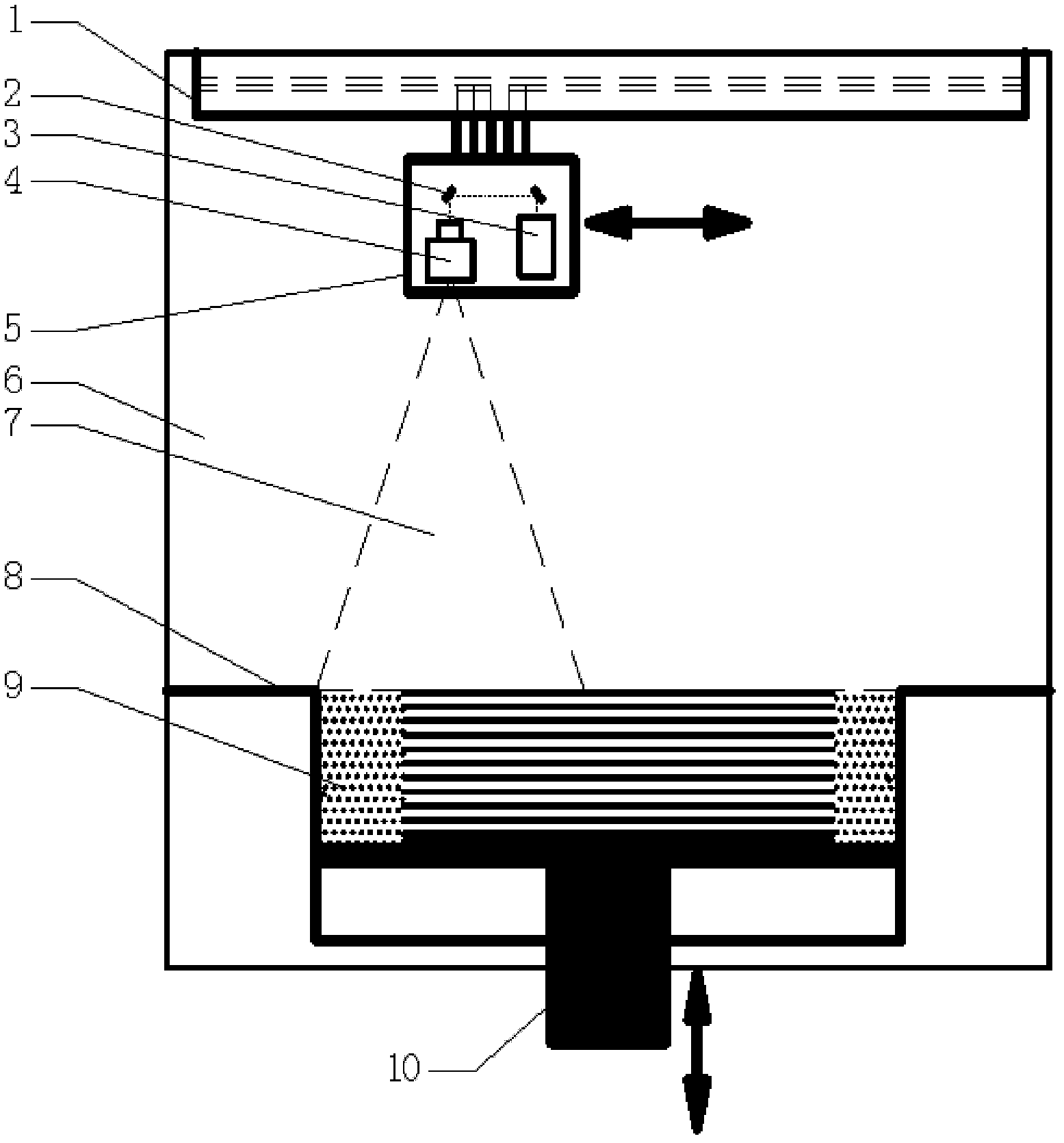

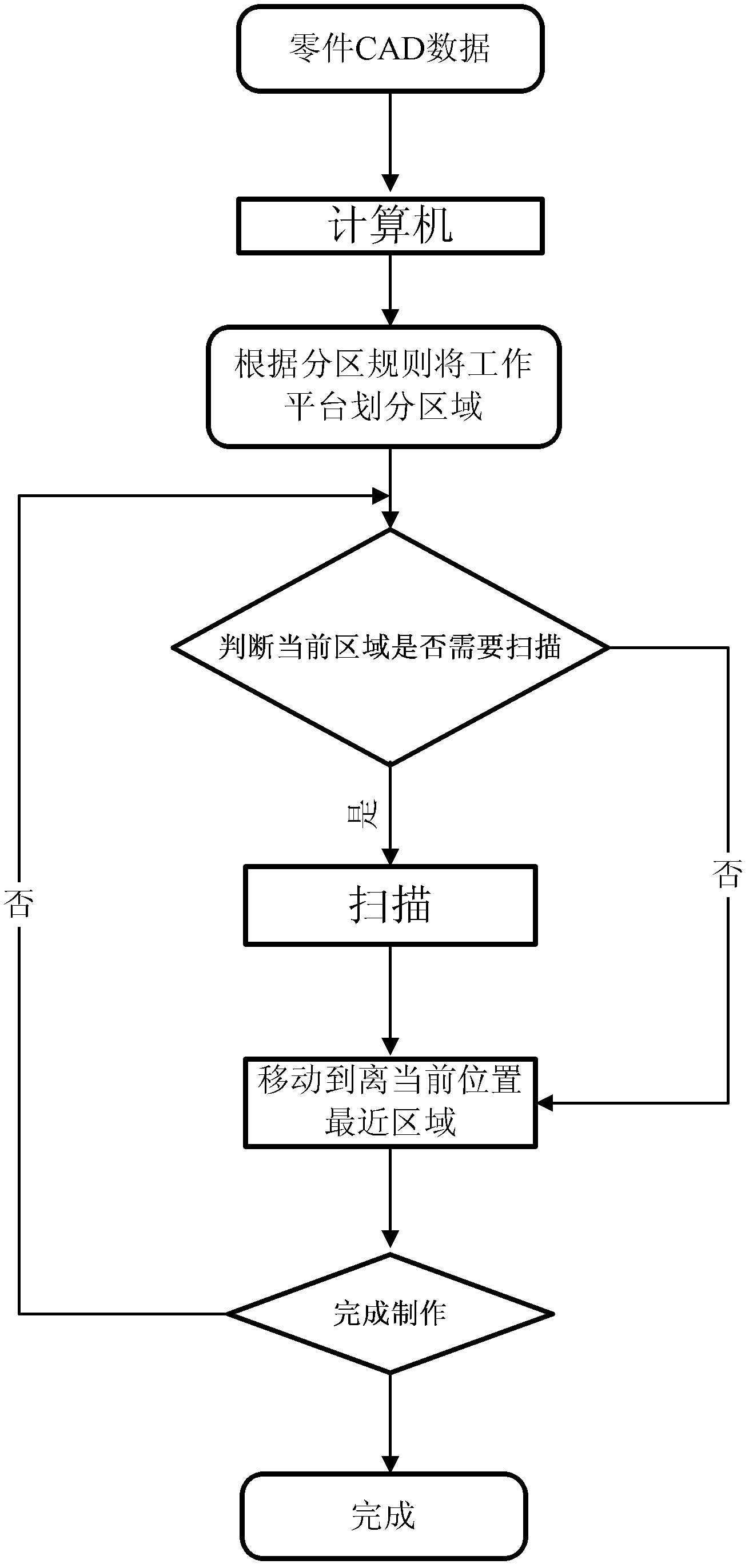

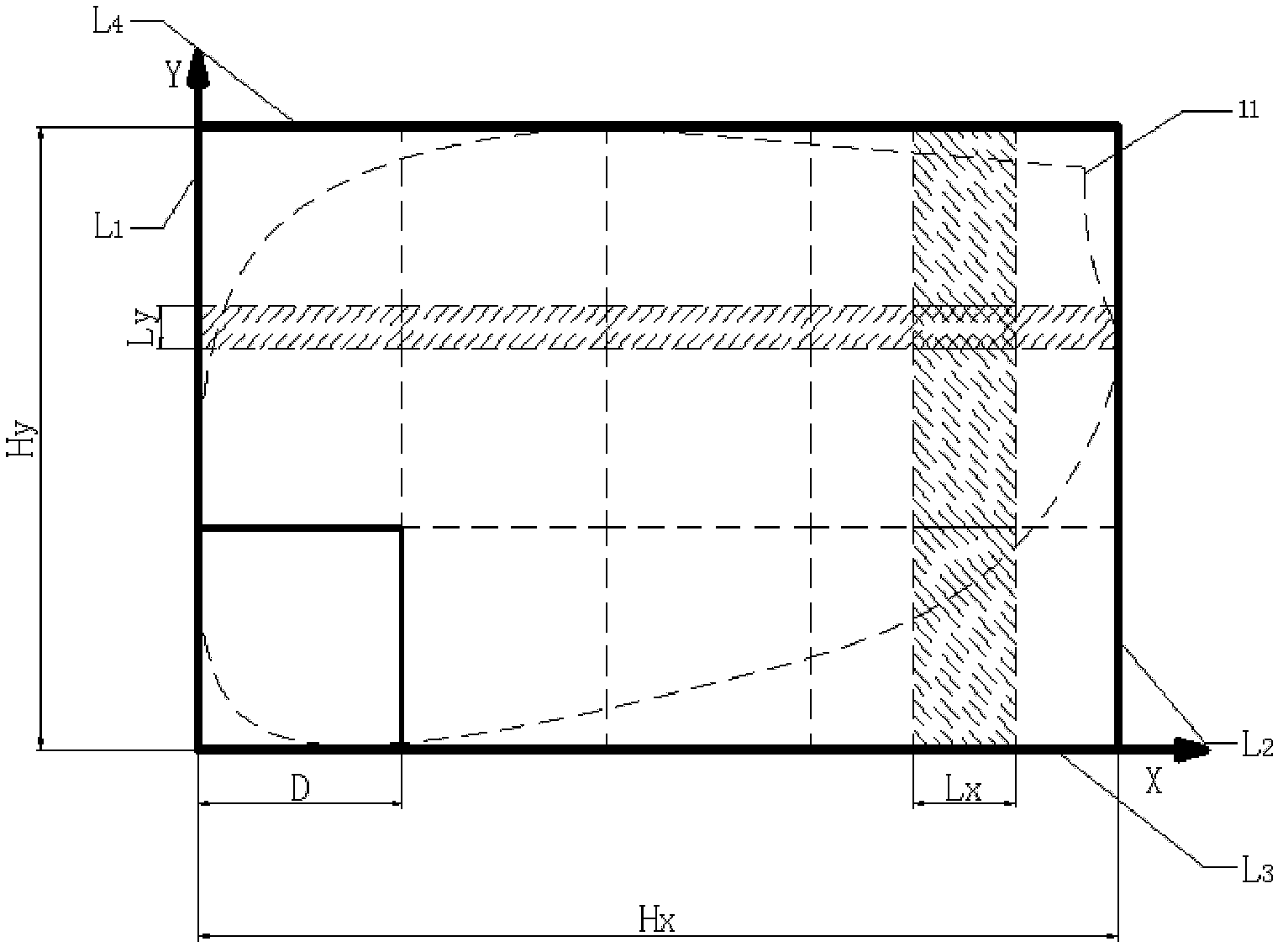

[0018] refer to figure 1 , a subregional mobile light source scanning system for laser rapid prototyping technology, including a subregional movable platform and a workpiece cavity 9 equipped with a piston 10, the subregional movable platform is fixed in the working casing 6 and is arranged in Above the workpiece chamber 9, the sub-area movable platform includes a linear motor platform 1 and a scanning platform 5, the linear motor platform 1 is suspended above the workpiece chamber 6 through a connector, the scanning platform 5 is fixed on the linear motor platform 1, and the scanning platform 5 includes Laser 3, scanning galvanometer 4 and reflector 2, reflector 2 is located above laser 3 and scan galvanometer 4, laser 3 is located on the right side of scan galvanometer 4, a computer output terminal containing scanning control program passes through the oscillating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com