Laminated double-sided multi-serpentine microchannel reforming hydrogen production reactor

A reforming hydrogen production and microchannel technology, applied in hydrogen, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as unfavorable catalyst coating, achieve the effect of increasing retention time, increasing conversion rate, and realizing scale expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

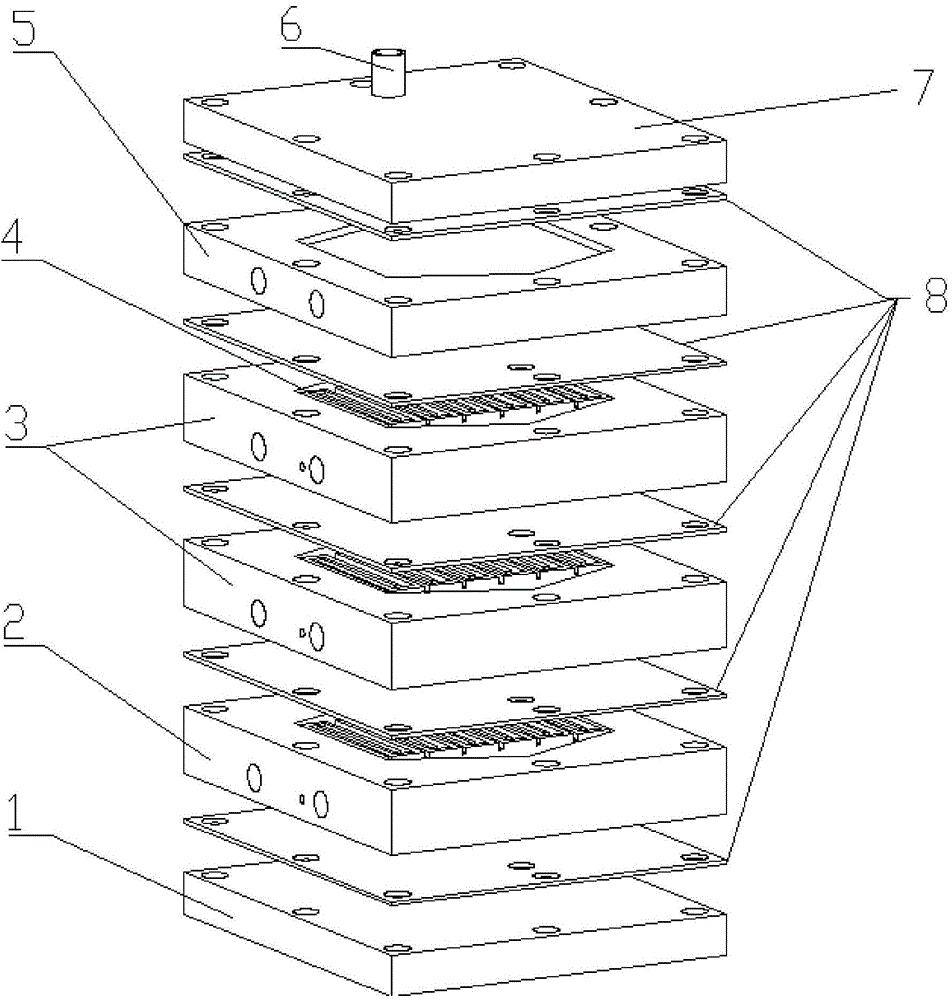

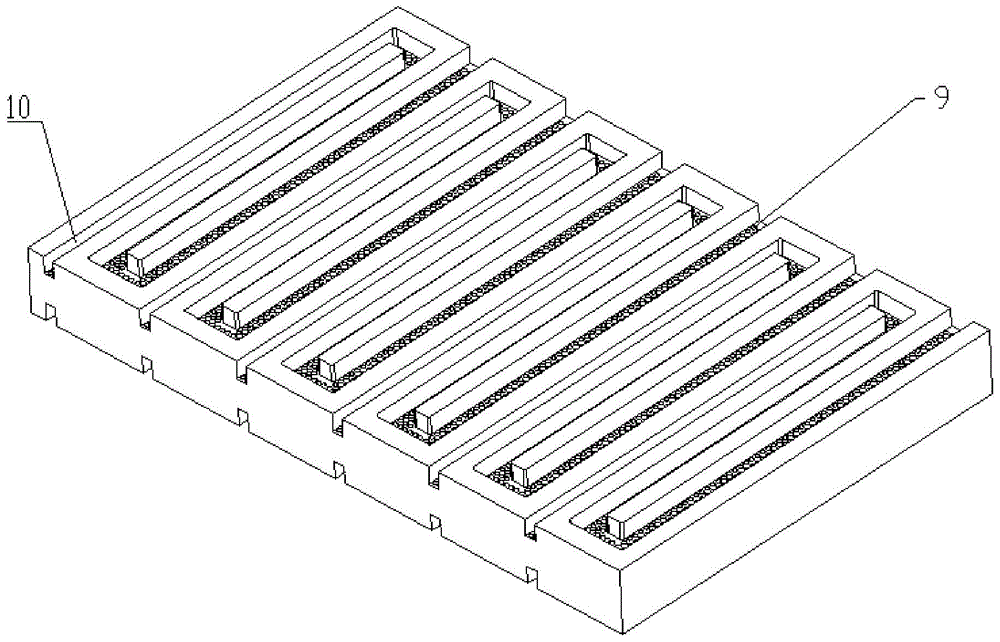

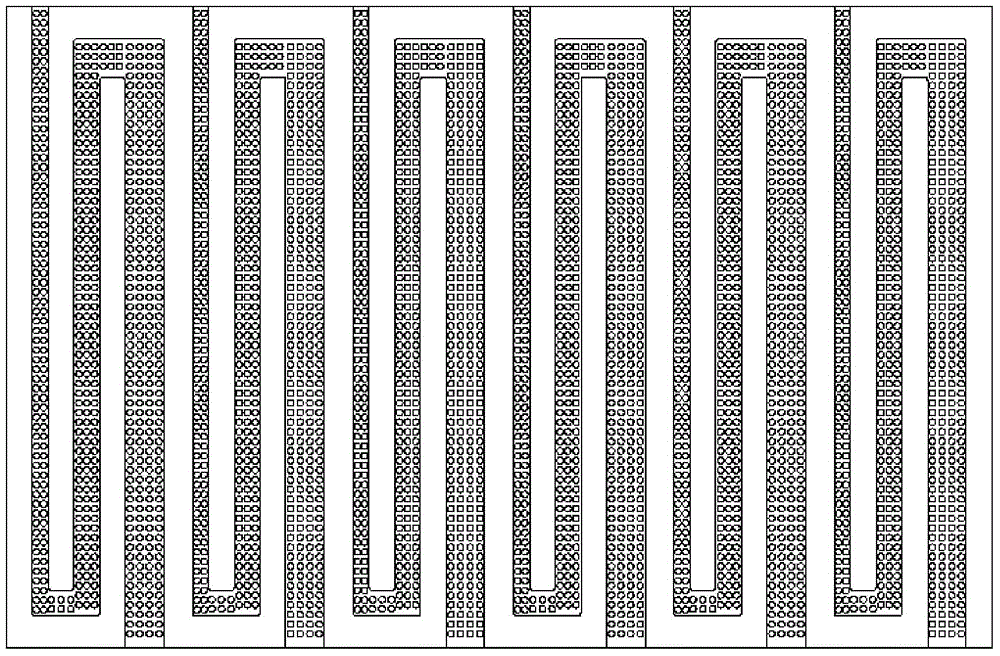

[0036] Such as figure 1 As shown, the present invention includes an upper cover plate 7, a lower cover plate 1, and an evaporation plate 5, a plurality of upper reforming plates 3 and a lower reforming plate sealed and installed in sequence between the upper cover plate 7 and the lower cover plate 1 2. The number of upper reforming plates 3 is 2-9 pieces, multiple upper reforming plates 3 are installed between the evaporation plate 5 and the lower reforming plate 2, the upper cover plate 7, the lower cover plate 1, the evaporation plate 5, Flexible graphite pads 8 are provided between any two adjacent installation surfaces of the plurality of upper reforming plates 3 and lower reforming plates 2 , and each plate is connected and assembled by bolts.

[0037] Such as figure 1 As shown, the upper cover plate 7 is equipped with an inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com