Self-insulation concrete hollow building block mold and manufacturing method of building blocks

A technology for hollow blocks and concrete, which is applied in the production of self-insulating concrete hollow blocks and molds for self-insulating concrete hollow blocks. It can solve the problems of inappropriate material integrity, low efficiency, and cumbersome production process. The method is simple and practical. , improve quality, and use conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

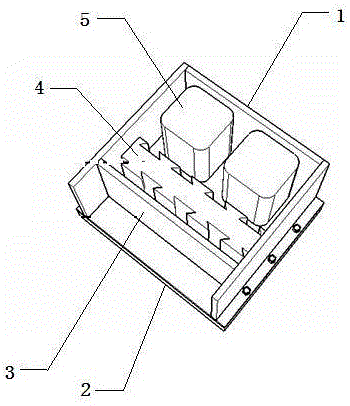

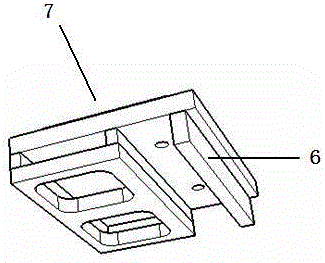

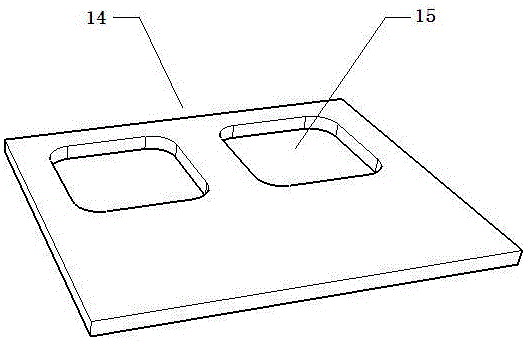

[0028] Such as Figure 1-4 shown.

[0029] A self-insulating concrete hollow block mold includes a bottom plate 2, a mold frame 1 and an upper pressing plate 7. The mold frame 1 is rectangular, and three side plates are fixedly connected, and the front side plate 3 is movably connected with the adjacent side plates by bolts, so that it can move back and forth as required to change the size of the mold frame 1. The bottom of the mold frame 1 is connected with the bottom plate 2 by bolts, and a thermal insulation board 4 is movably arranged in the mold frame 1 . The insulation board 4 is in the shape of a strip, and a plurality of wedge-shaped grooves are arranged on both sides, so as to be able to be firmly connected with the blocks. The length of the thermal insulation board 4 can be about 0.2mm longer than the width of the corresponding mold frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com