Manufacturing method of three-dimensional large-sized artificial rock core

A technology of artificial core and production method, which is applied in the petroleum field, can solve the problems of large differences in the mechanical properties of the sintering model and the degree of cementation of the reservoir, the inability to meet the temperature, high pressure, and inability to meet the requirements of medium and high pressure, and achieve low cost and source Broad, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0051] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

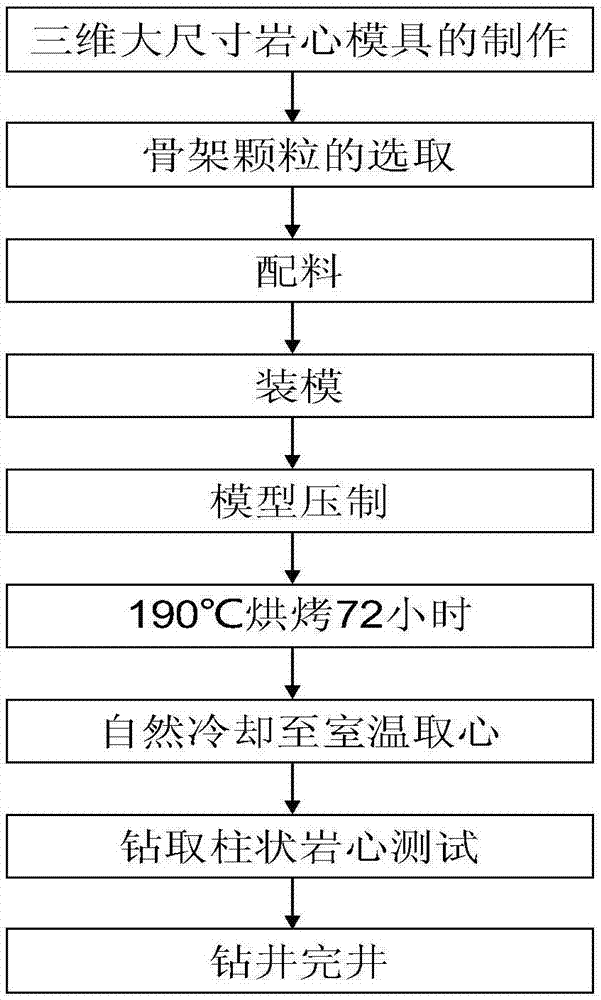

[0052] according to figure 1 The process shown is to make a three-dimensional large-scale artificial core:

[0053] (1) Manufacture of three-dimensional large-scale core mold: formulate the mold size according to the required core size (300×300×200mm), process the production material into a 20cm thick steel plate, 4 side plates, 1 bottom plate, and 4 pieces The steel plates are joined together in a detachable way with screws (easy to demould) into a cube box shape, hollow, and a briquetting block matching the mold is made.

[0054] (2) Selection of skeleton particles: According to the particle size test results of natural rock cores, river sand and some reservoir rock particles with a particle size distribution similarity of 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com