A molding die for rod-shaped insulator pillars for high-speed railways

A technology for high-speed railways and forming molds, applied in the direction of insulators, supporting insulators, circuits, etc., can solve the problems of prolonging processing hours, excessive scrapping, shrinkage cavities, etc., and achieve the effects of saving materials, avoiding turning processing, and improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

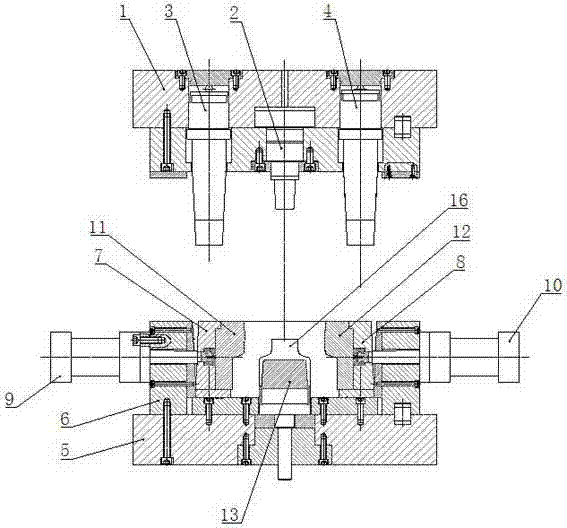

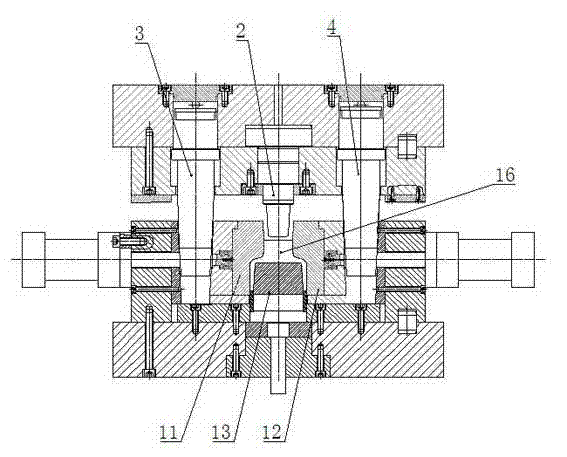

[0014] like figure 2 As shown, it includes upper template 1, upper punch 2, left die locking cylinder 3, right die locking cylinder 4, lower template 5, die base 6, left die 7, right die 8, left cylinder 9. Right cylinder 10.

[0015] The upper punch 2 is installed in the center of the above-mentioned upper template 1, and the vertical left die locking cylinder 3 and the right die locking cylinder 4 are respectively installed on both sides. The piston rod ends of the two die locking cylinders 3 and 4 The top is conical or wedge-shaped.

[0016] Die holder 6 is installed on the lower template 5, left die 7, right die 8 are arranged in the die holder 6, left side cylinder 9 and right side cylinder 9 are installed on the outside die holder 6 of left die 7 and right die 8 Cylinder 10, the cylinder body of left side cylinder 9, right side cylinder 10 is connected and fixed with die base 6, and piston rod is connected with left die 7 and right die 8 respectively.

[0017] The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com