Manufacturing method and structure of integrated prefabricated thermal-insulation wallboard and wallboard connecting assembly

A technology for connecting components and thermal insulation wall panels, which is applied in thermal insulation, building components, manufacturing tools, etc., can solve the problems of affecting component stiffness distribution, long construction period, and small application range, so as to improve processing efficiency, reduce processing cost, and achieve thermal insulation effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 discloses a method for manufacturing an integrated prefabricated thermal insulation wallboard, including steps:

[0049] S10: layering the thermal insulation material with the exterior finish;

[0050]S20: connecting the thermal insulation material and the outer finish layer through the connecting component, and the connecting component protrudes from the thermal insulation material;

[0051] S30: laying the thermal insulation material and the outer finish layer in the component mold;

[0052] S40: Concrete walls are poured on the side of the insulating material having the protruding connection components.

[0053] Specifically, step S20 further includes the steps of:

[0054] S21: Reserving installation holes on the exterior finish layer and the heat preservation material respectively;

[0055] S22: through the threaded connector in the connection assembly, pass through the installation hole on the outer finish layer and extend into the installation hol...

Embodiment 2

[0061] The manufacturing method of the integrated prefabricated thermal insulation wallboard disclosed in the second embodiment is basically the same as that of the first embodiment, the only difference is that in the second embodiment, step S20 of the manufacturing method of the integrated prefabricated thermal insulation wallboard further includes steps:

[0062] S21: Reserve installation holes on the insulation material;

[0063] S22: The threaded connector in the connection assembly passes through the outer finish layer through self-drilling and extends into the installation hole on the thermal insulation material, and the threaded connector connects the outer finish layer and the thermal insulation material;

[0064] S23: Thread the threaded sleeve in the connection assembly to the threaded connector, the first end of the threaded sleeve protrudes out of the thermal insulation material, and the second end of the threaded sleeve passes through the installation hole on the t...

Embodiment 3

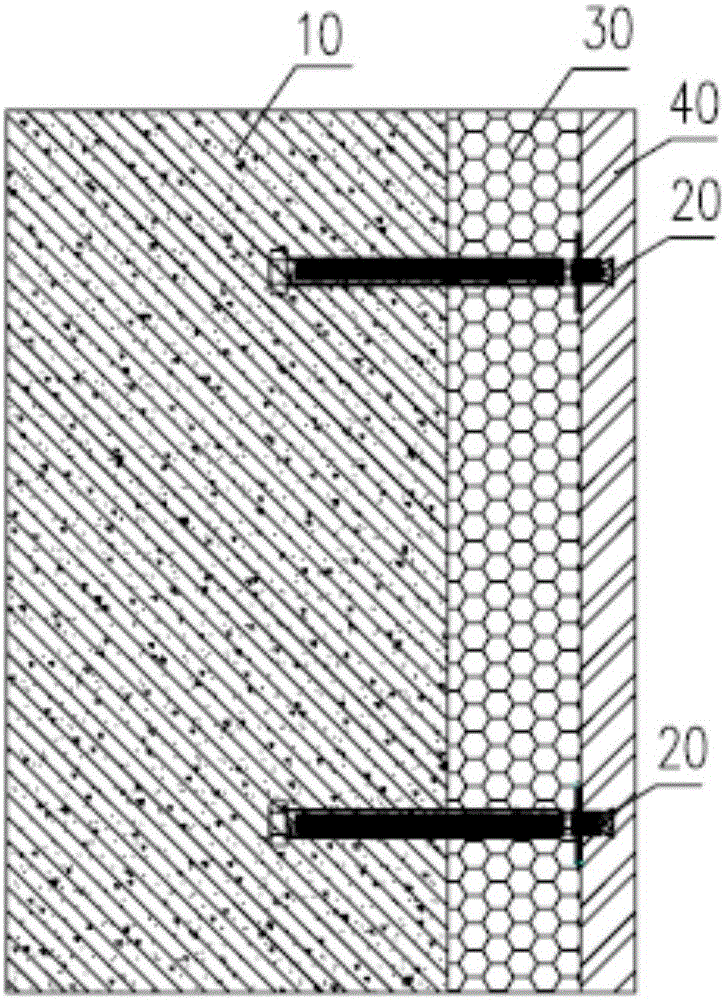

[0069] Such as Figure 1 to Figure 4 As shown, Embodiment 3 discloses an integrated prefabricated thermal insulation wall panel structure prepared by the integrated prefabricated thermal insulation wall panel manufacturing method disclosed in Embodiment 1, including: a concrete wall 10, pre-embedded with a connecting component 20, And the connection assembly 20 protrudes from the concrete wall 10 ; the insulation material 30 is laminated with the concrete wall 10 through the connection assembly 20 ; the exterior finish layer 40 is laminated with the insulation material 30 through the connection assembly 20 .

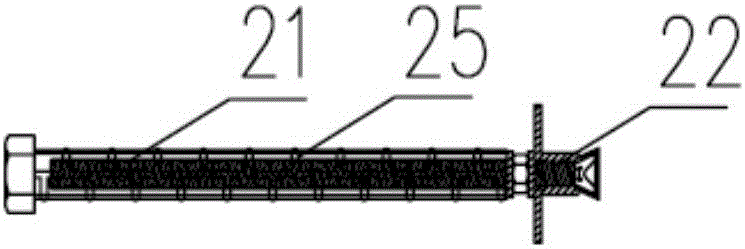

[0070] Such as image 3 As shown, the connection assembly 20 includes a threaded sleeve 21 and a threaded connector 22 , and the threaded connector 22 and the threaded sleeve 21 are connected through threaded fit. Mounting holes are respectively reserved on the outer finish layer 40 and the thermal insulation material 30 , the mounting holes on the outer finish layer 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com