High-temperature adhesive tape solder preparation device and method

A technology for preparing device and adhesive tape, which is applied to manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of insufficient strength, long production cycle of adhesive tape brazing material, difficult operation, etc. Continuous production, thickness can be adjusted arbitrarily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

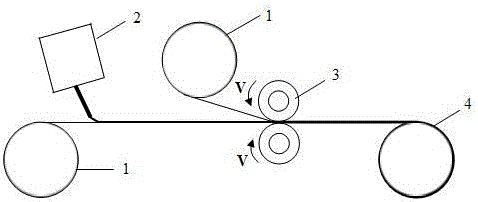

Image

Examples

Embodiment 1

[0028] To prepare a nickel-based high-temperature adhesive tape solder with a thickness of 2.0 mm, the operation steps are as follows:

[0029] (1) Take 170g of binder and 830g of nickel-based high-temperature solder powder with a mesh number of -100~800 mesh, mix and stir evenly to form a paste;

[0030] (2) Pour the paste into the extrusion barrel of the extruder, and install the needle;

[0031] (3) Adjust the roller spacing to 2.2mm;

[0032] (4) Start the preparation device, adjust the rotation speed of the rolls, the release paper tray, the receiving tray and the rolls run synchronously, pass the upper and lower layers of release paper through the gap between the rollers, and then wind them on the receiving tray;

[0033] (5) Start the extruder, extrude a strip paste on the center line of the lower release paper, the strip paste forms a strip-shaped solder under the co-extrusion of the release paper and the roll, and then collect it in the receiving In the plate;

[0...

Embodiment 2

[0037] To prepare a copper-based high-temperature adhesive tape solder with a thickness of 1.5 mm, the operation steps are as follows:

[0038] (1) Take 130g of binder and 870g of copper-based high-temperature solder powder with a mesh number of -150~800 mesh, mix and stir evenly to form a paste;

[0039] (2) Pour the paste into the extrusion barrel of the extruder, and install the needle;

[0040] (3) Adjust the roller spacing to 1.7mm;

[0041] (4) Start the preparation device, adjust the rotation speed of the rolls, the release paper tray, the receiving tray and the rolls run synchronously, pass the upper and lower layers of release paper through the gap between the rollers, and then wind them on the receiving tray;

[0042] (5) Start the extruder, extrude a strip paste on the center line of the lower release paper, the strip paste forms a strip-shaped solder under the co-extrusion of the release paper and the roll, and then collect it in the receiving In the plate;

[0...

Embodiment 3

[0046] To prepare a cobalt-based high-temperature adhesive tape solder with a thickness of 1.0 mm, the operation steps are as follows:

[0047] (1) Take 70g of binder and 930g of cobalt-based high-temperature solder powder with a mesh number of -325~800, mix and stir evenly to form a paste;

[0048] (2) Pour the paste into the extrusion barrel of the extruder, and install the needle;

[0049] (3) Adjust the roller spacing to 1.2mm;

[0050] (4) Start the preparation device, adjust the rotation speed of the rolls, the release paper tray, the receiving tray and the rolls run synchronously, pass the upper and lower layers of release paper through the gap between the rollers, and then wind them on the receiving tray;

[0051] (5) Start the extruder, extrude a strip paste on the center line of the lower release paper, the strip paste forms a strip-shaped solder under the co-extrusion of the release paper and the roll, and then collect it in the receiving In the plate;

[0052] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com