Solid freeform fabrication using a plurality of modeling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

System Operation Protocols

[0282]In the present Example, an object is defined as a volume in space (usually specified in an X, Y, Z coordinate system) which is confined by one or more close surfaces which do not intersect with each other (see, e.g., FIG. 2a). A region in the object is a sub-volume of the object which is confined in one or more close surfaces which do not intersect with each other (see, e.g., FIG. 2b)

[0283]A communication file is a file in which the specification of an object is saved by the CAD Software and from which the solid freeform fabrication apparatus retrieves the full information on the object. The structure and format of the communication file is known to both the CAD and the software controlling the solid freeform fabrication apparatus.

[0284]An STL file is an example of communication files that both CAD and the software controlling the solid freeform fabrication apparatus recognize. In an STL file, the object is specified by a series of triangles that opti...

example 2

Exemplified Workflow

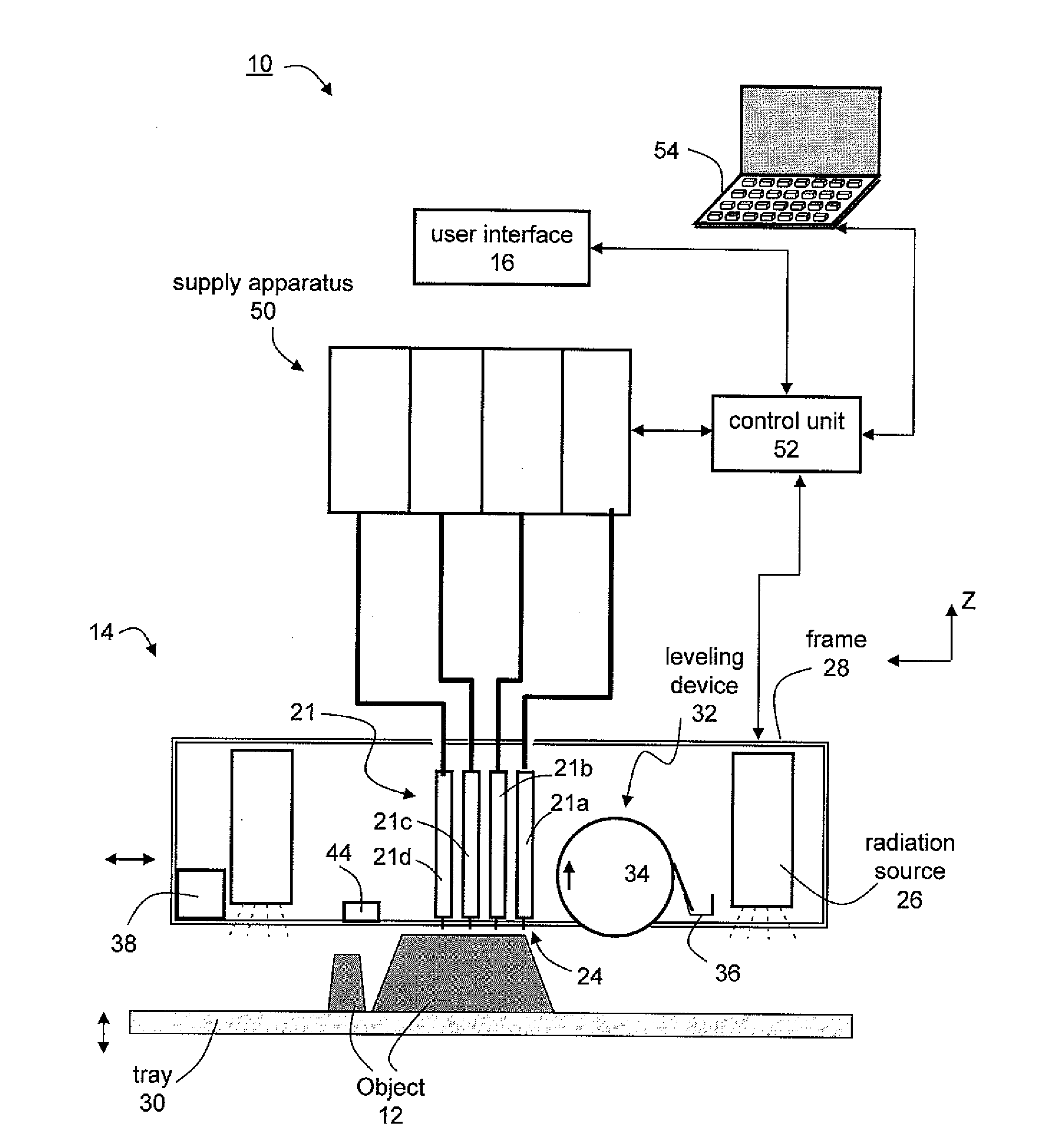

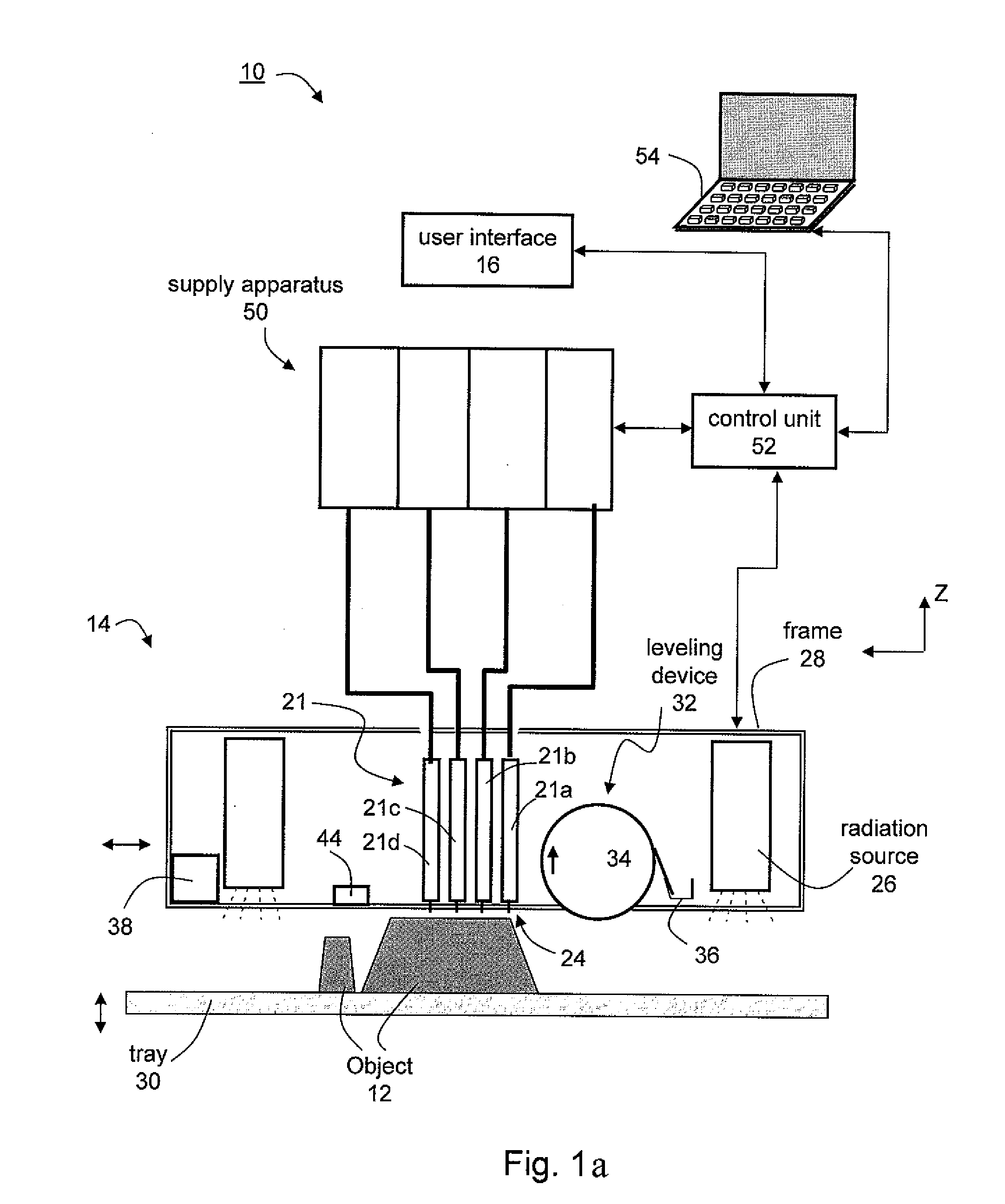

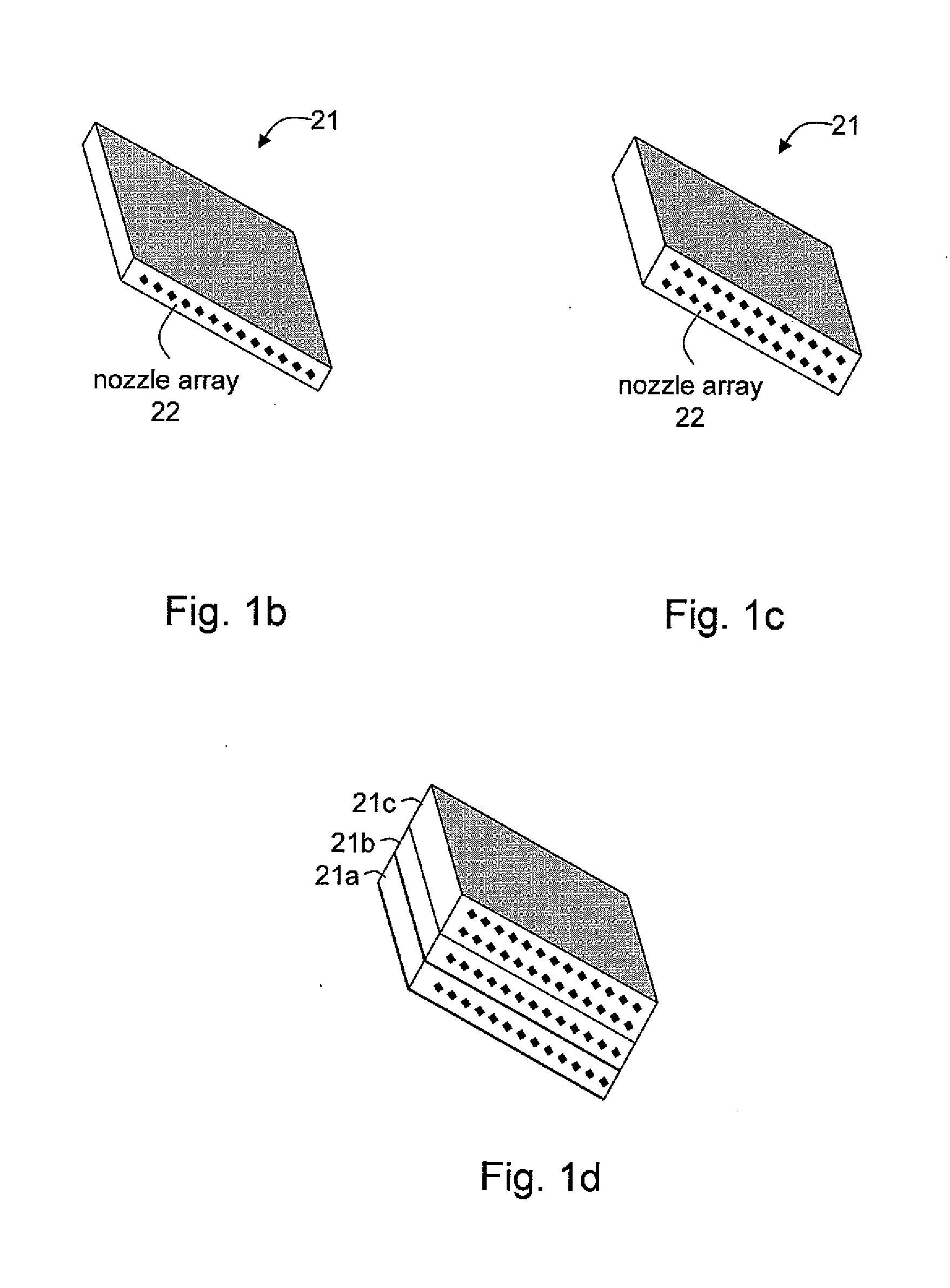

[0294]The present Example describes a workflow for building one or more three-dimensional objects from several materials, according to some embodiments of the present invention. The workflow includes several stages which can be executed by the user or automatically.

[0295]The solid freeform fabrication apparatus is fed by different input materials, each being fed into a different container. In the following, N represents the number of different input materials. It is noted that the number of occupied containers in the solid freeform fabrication apparatus can be more than N, in which case two or more containers include the same material.

[0296]A computer, which is capable of communicating with the solid freeform fabrication apparatus, receives a list of groups of input materials which are allowed to be fed together into the apparatus. Each group can comprise from 2 to N combinable input materials. Materials which are not allowed to combine are not included in the sa...

example 3

Software Application for Combining 2 Materials in an Object

[0303]The background art fails to teach how different building materials can be used in order to build complex object assemblies and how a communication file representing a three dimensional object can be manipulated in order to build a three dimensional object comprising more than one material.

[0304]The following example describes a method suitable for designing and building an object from a composite material. The method enables the definition of composite material structures, without the need for standard CAD software in order to design the full three-dimensional structure, thus saving on the time that would be required for the design process as well as saving computer memory resources which would usually be required in order to design three-dimensional structures and for the analysis of such three-dimensional structure during the building process.

General

[0305]The method comprises Boolean comparison between bitmaps repres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com