Metal thin film /foil dynamic performance critical characteristic dimension test system and method

A technology of metal thin film and characteristic scale, which is applied in the direction of testing the strength of materials by applying a stable bending force, can solve the problems that the basic mechanical theory and mechanical performance parameters are no longer applicable, and achieve the effect of easy preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 The critical characteristic scale l of the mechanical properties of SUS304 stainless steel foil c value calculation

[0051] (1) Sample preparation

[0052] The SUS304 stainless steel foils with thicknesses of 25 μm and 50 μm after rolling and annealing were cut into 10×4mm by wire cutting 2 The sample was subjected to short-term electrolytic polishing to clean its surface, and finally 5 samples of each of the two thicknesses were prepared.

[0053] (2) Micro-bending experiments on stainless steel foil samples

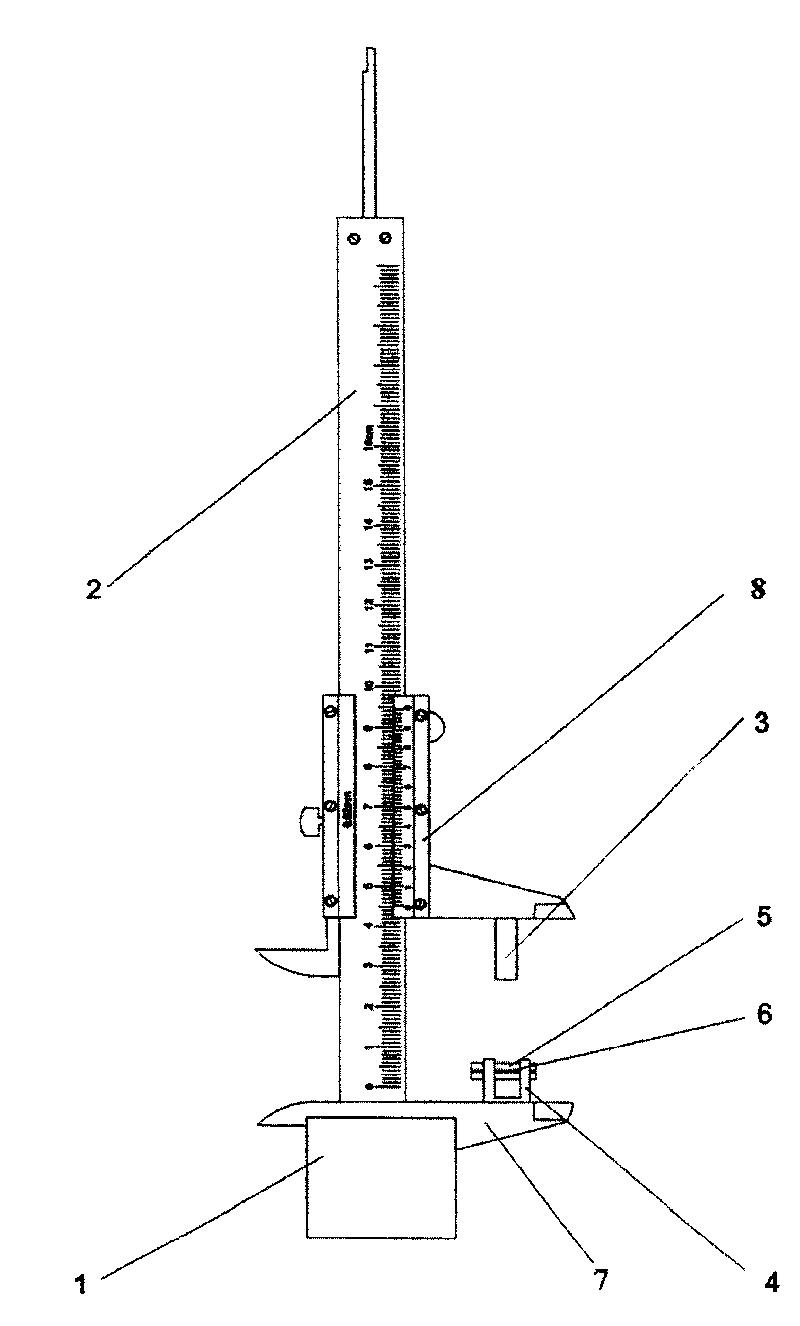

[0054] Mandrels with diameters of 240 μm, 546 μm and 1000 μm were used for micro-bending experiments on foil samples with a thickness of 25 μm; for foil samples with a thickness of 50 μm, mandrels with diameters of 480 μm, 1092 μm and 2000 μm were used. Such as figure 1 As shown, fix the pusher 2 head down on the base 1, select a pair of mandrels 5 and clamp the sample 6 in between, and then put them together into the lower mold 4 of the sample loa...

Embodiment 2

[0061] Example 2 Measurement and Calculation of Critical Characteristic Scales of Mechanical Properties of Polycrystalline Copper Thin Films

[0062] (1) Preparation of samples

[0063] Use wire cutting to cut a piece of bulk polycrystalline copper material with a size of 10×4×0.5mm 3 The sample was then mechanically ground and thinned to a thickness of 0.08-0.1mm, and then electropolished to obtain two single-crystal copper thin film samples with thicknesses of 25 μm and 50 μm respectively.

[0064] (2) Micro-bending experiments on copper thin film samples

[0065] Mandrels with diameters of 240 μm, 546 μm and 1000 μm were used for microbending experiments on film samples with a thickness of 25 μm; for film samples with a thickness of 50 μm, mandrels with diameters of 480 μm, 1092 μm and 2000 μm were used. Such as figure 1 As shown, fix the pusher 2 head down on the base 1, select a pair of mandrels 5 and clamp the sample 6 in between, and then put them together into the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com