Amorphous alloy coating tension device using with nanoindentor and use method thereof

A nano-indenter and amorphous alloy technology, applied in the direction of measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve temperature drift, difficult nano-indenter combined with micro-nano mechanical behavior , Sample surface flatness requirements are very high, to achieve the effect of precise control of strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

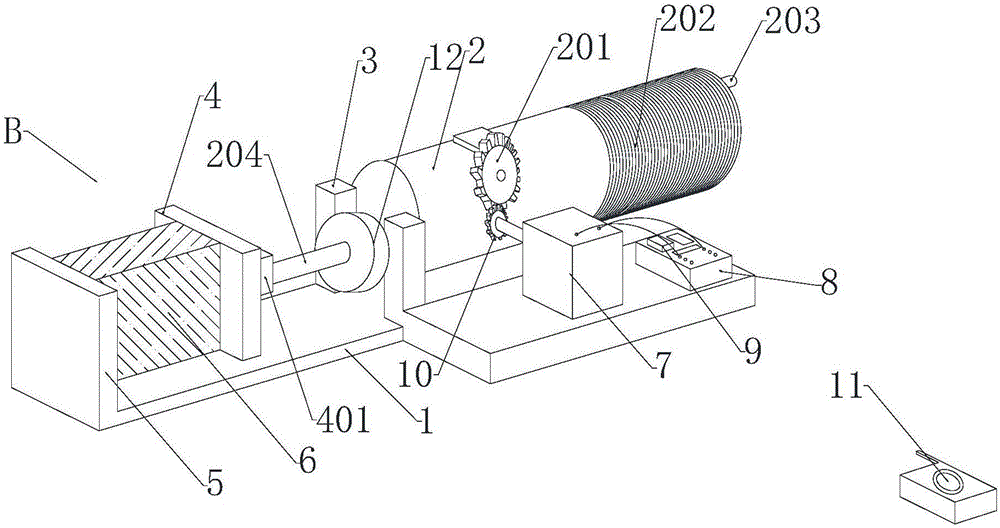

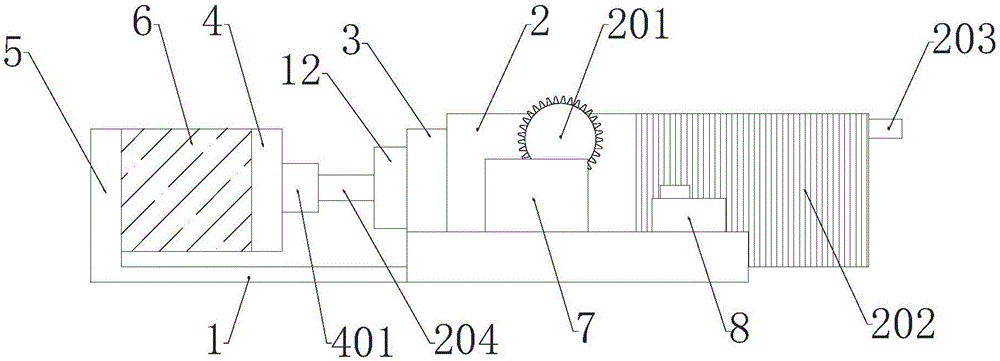

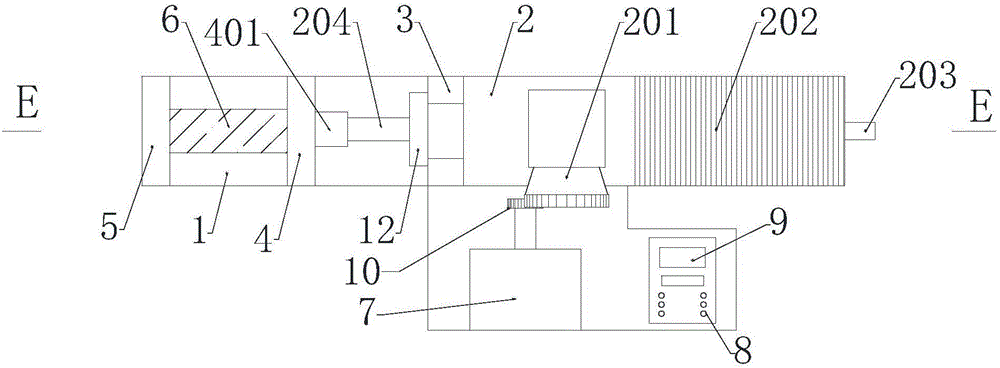

[0085] like figure 1 , an amorphous alloy coating stretching device B used in conjunction with a nano-indentation instrument A, the device B includes a base 1, a high-precision turbine type coarse and fine-tuning differential head 2, a fixed column 3, a movable baffle 4, a fixed baffle Board 5, elastic substrate 6, motor 7, motor power supply 8. One end of the base 1 is provided with a fixed baffle 5 . The other end of the base 1 is provided with a fixed column 3 . The high-precision turbine type coarse and fine adjustment micrometer head 2 is arranged on the fixed column 3 and connected with the telescopic rod connector 401 on the movable baffle 4 . The movable baffle 4 is located between the fixed baffle 5 and the fixed column 3 . The elastic substrate 6 is clamped between the movable baffle 4 and the fixed baffle 5 and does not contact the base 1 . The motor 7 is connected with the high-precision turbine type coarse and fine adjustment differential head 2 through the ge...

Embodiment 2

[0088] Implementation 1 is repeated, except that the device B also includes a control system 14 . The control system 14 includes a receiving device 9 and a remote control device 11 . The control system 14 connects and controls the motor power supply 8 and the motor 7 .

Embodiment 3

[0090] Repeat implementation 2, but the motor 7 is connected with the high-precision turbine type coarse and fine adjustment differential head 2 through gears.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com