Method for driving amorphous alloy to achieve rejuvenation by applying cyclic loading mode

A technology of cyclic loading and amorphous alloys, which is applied in the field of amorphous alloy materials, can solve problems such as poor effects, and achieve the effects of promoting rejuvenation, good rejuvenation effects, and decreased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of La 60 Ni 25 al 15 Amorphous alloy plate: La, Ni and Al with a purity of ≥99.9% are mixed according to the atomic percentage of 60:25:15, and then melted in an electric arc melting furnace under the protection of a high-purity argon atmosphere. Repeat smelting 5 times to form an alloy ingot. Using the method of vacuum suction casting, the alloy ingot is melted and sucked into a copper mold, wherein the size of the copper mold is 65x5x2mm, and a La-based amorphous alloy sample is prepared.

[0026] (2) Preliminary treatment: wire-cut the amorphous alloy block obtained in step (1) into a block sample with a size of 40x2x1mm, use #400-#2000 sandpaper to grind the upper and lower bottom surfaces of the strip sample from small to large, Then it is polished to a mirror surface, and annealed at 100° C. for 1 hour under the protection of nitrogen.

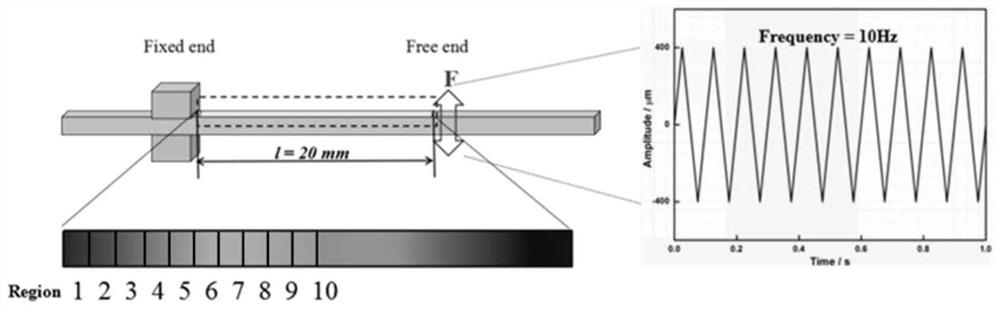

[0027] (3) Single cantilever beam cyclic loading treatment: place the sample on the Q800 DMA single cantilev...

Embodiment 2

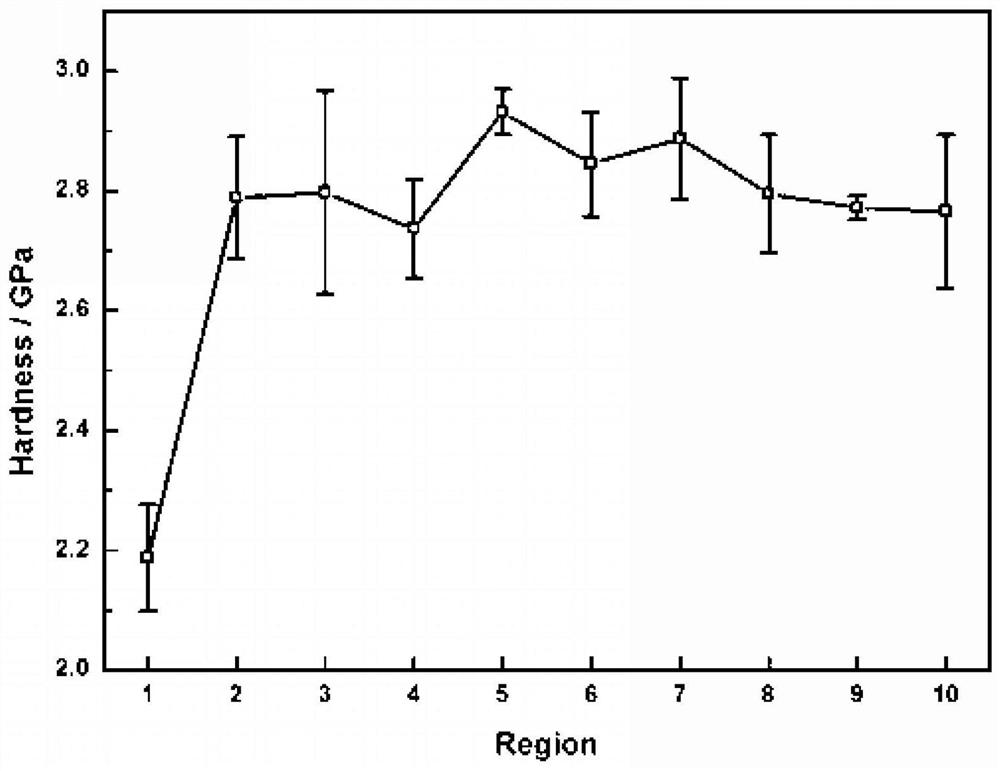

[0031] Figure 4 It is the hardness distribution on the surface of the annealed lanthanum-based amorphous alloy sample before and after 2 hours of cyclic loading with a span of 5 mm and a frequency of 10 Hz in the present invention. Figure 4 Area 1 is close to the fixed end, area 4 is close to the free end, and the interval between the center points of the area is 1mm. It can be seen from the figure that the hardness of the sample is uniformly distributed when it is not loaded, and after loading, it is close to the fixed end. The hardness of the area decreased by 26% relative to that before cyclic loading.

[0032] The present invention provides a method for driving rapid rejuvenation of an amorphous alloy, the steps of which are basically the same as in Embodiment 1, the difference being that the span of a single cantilever beam is 5mm.

[0033] Result detection:

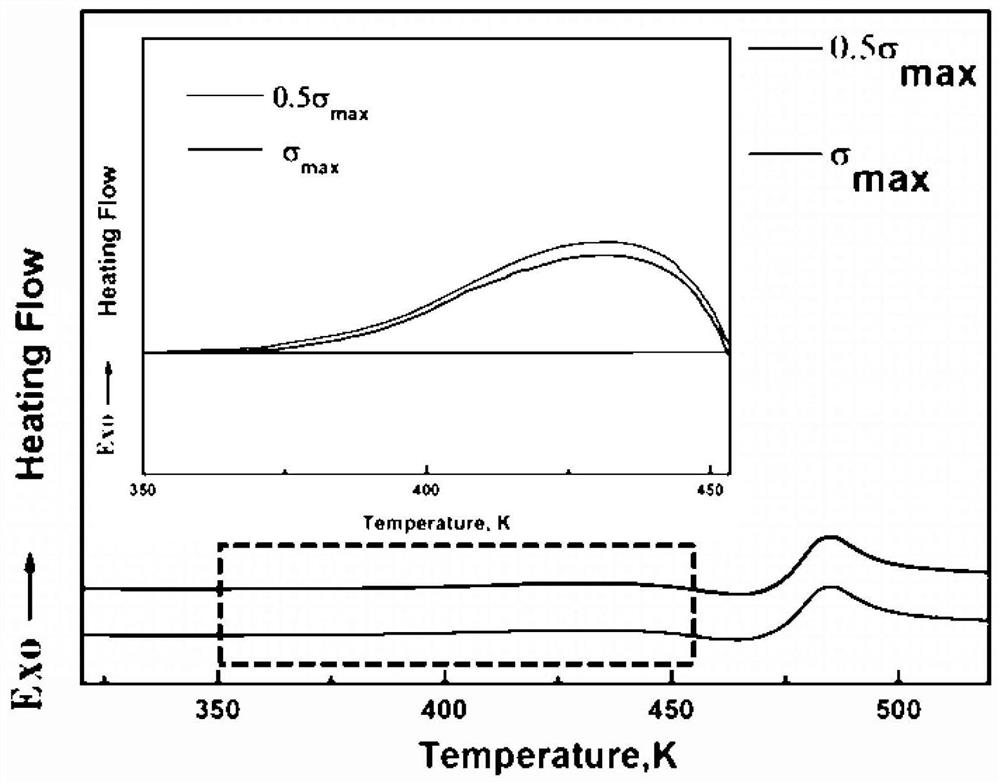

[0034] The rejuvenated lanthanum-based amorphous alloy sample was used for nanoindentation test, and the surf...

Embodiment 3

[0036] The present invention provides a method for driving rapid rejuvenation of amorphous alloys, the steps are basically the same as those in Example 1, the difference is that the lanthanum-based amorphous alloy is loaded with a single cantilever beam with a span of 5mm, and the temperature is controlled to cycle at 200K It took 1 hour to load. Result detection: The nano-indentation test was carried out on the rejuvenated lanthanum-based amorphous alloy sample, and it was found that the hardness decreased near the fixed end, but the hardness decreased by 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com