Mechanical characterization method for subsurface damage of optical glass

A technology of subsurface damage and optical glass, applied in scientific instruments, measuring devices, instruments, etc., can solve the problems of limited mechanical properties, cumbersome process, and the detection results are greatly affected by the environment, so as to achieve strong engineering applicability and improve measurement efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The above solution will be further described below in conjunction with specific embodiments.

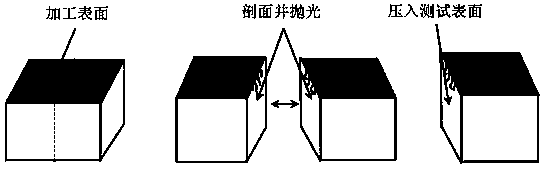

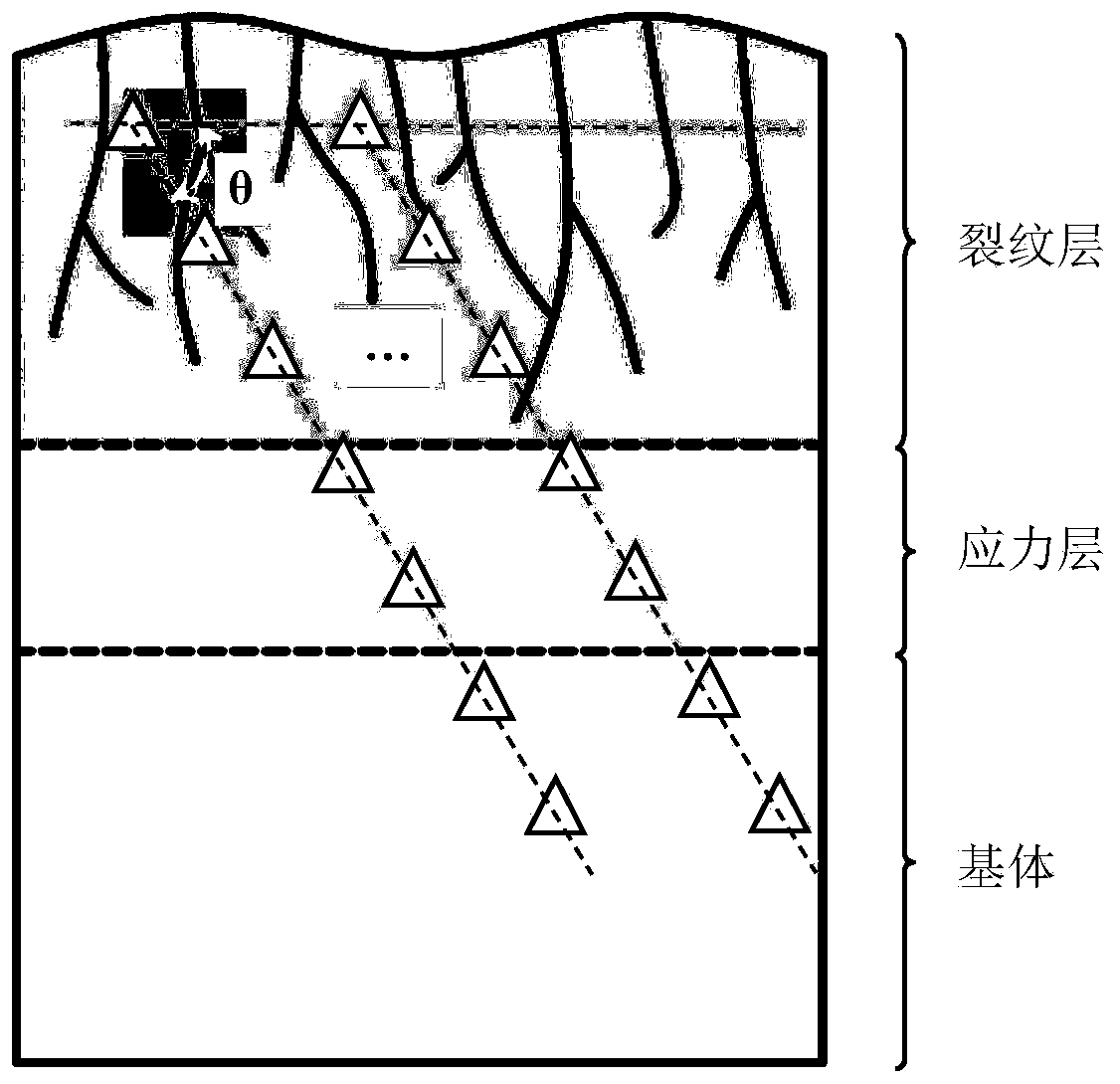

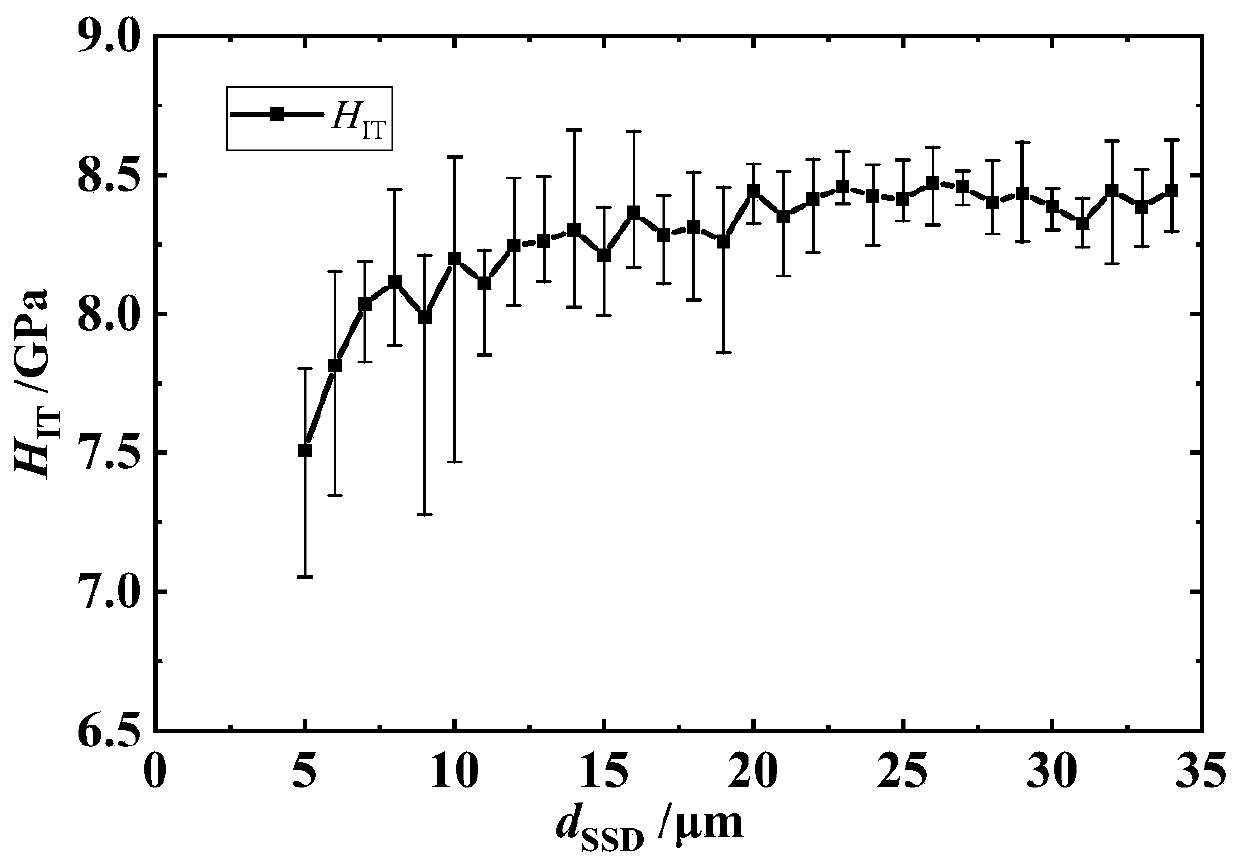

[0023] The mechanical action of optical glass in abrasive processing produces subsurface damage mainly cracks. Subsurface damage changes the microstructure of the surface layer of the material, thereby changing the mechanical properties of the surface layer of the sample. Therefore, the characterization parameters of the damaged layer should include geometric indexes and mechanical indexes. The invention uses a nano indenter to measure the high resolution of the mechanical index in the micro / nano scale range of the material, detects the gradient change of the mechanical index along the depth in the damaged layer section, and then determines the subsurface damage depth through the change curve, and tests the sample preparation process like figure 1 shown.

[0024] In this example, the mechanical characterization method for optical glass subsurface damage disclosed in the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com