Loading method and device for measuring micromechanical property of material under action of stress

A loading device and micromechanics technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve problems such as unsuitable, oversized loading device size, difficult sample loading, etc., to simplify the loading process and simplify The effect of the load method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] When the present invention qualitatively and quantitatively studies the nanomechanical properties of materials under stress, it is necessary to process a loading device suitable for the NanoIndenter (MTS, USA) nanoindenter, and design a test sample that meets the loading device according to the purpose of the experiment. Experimental purpose After loading the sample, use the nano indenter to test the loaded sample.

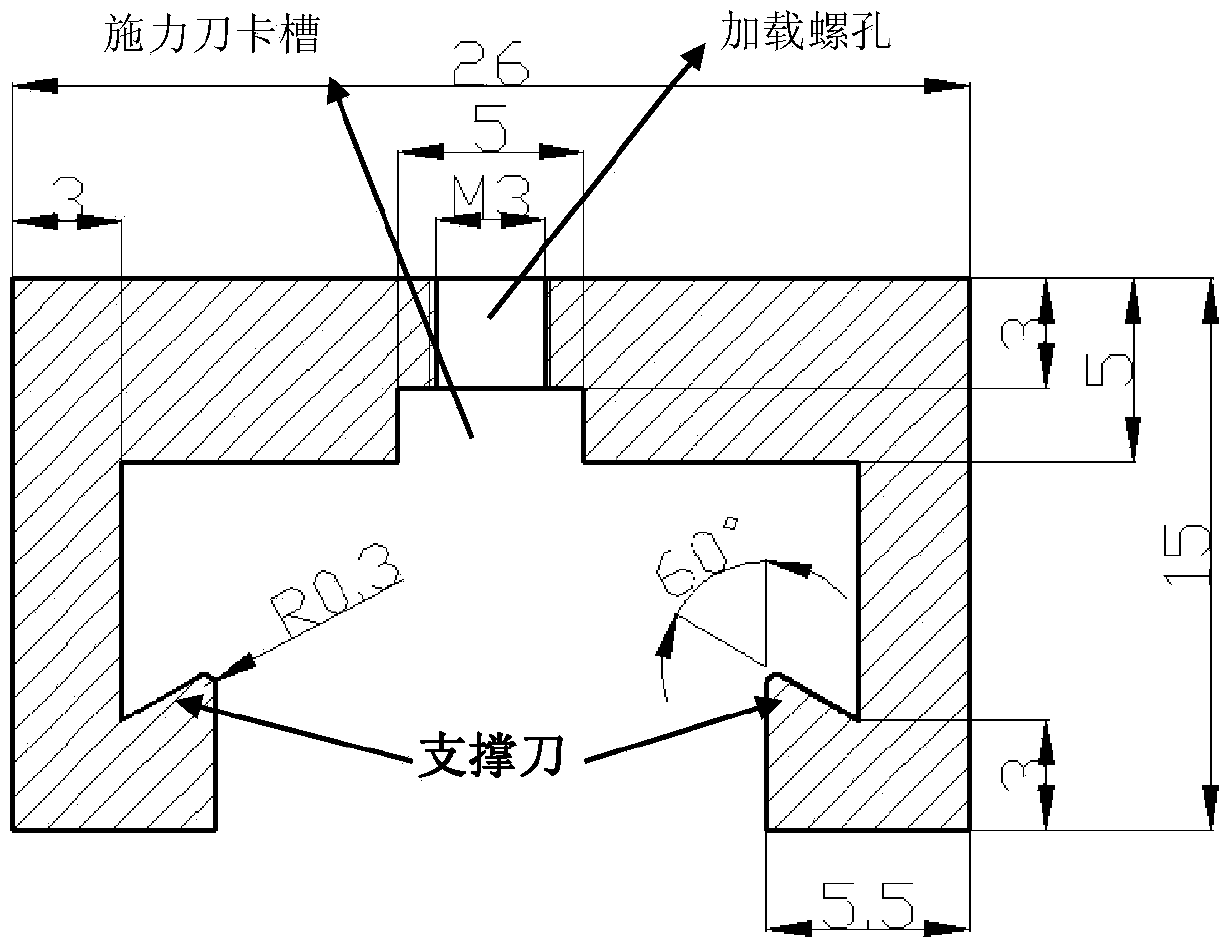

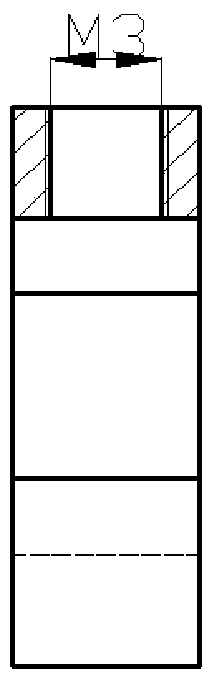

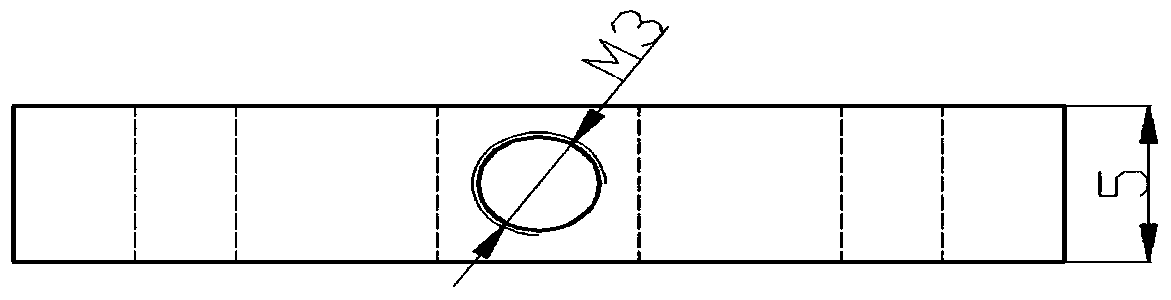

[0040] Figures 1-3 respectively show three views of the main body of the loading device, the force applying knife and the screw of the loading device. Its dimensions are marked in the figure, and the unit is mm;

[0041] (a) The main body of the loading device is in the shape of a hollow frame with an opening at the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com